Looking for a reliable and precise solution to handle sheet metal packages?

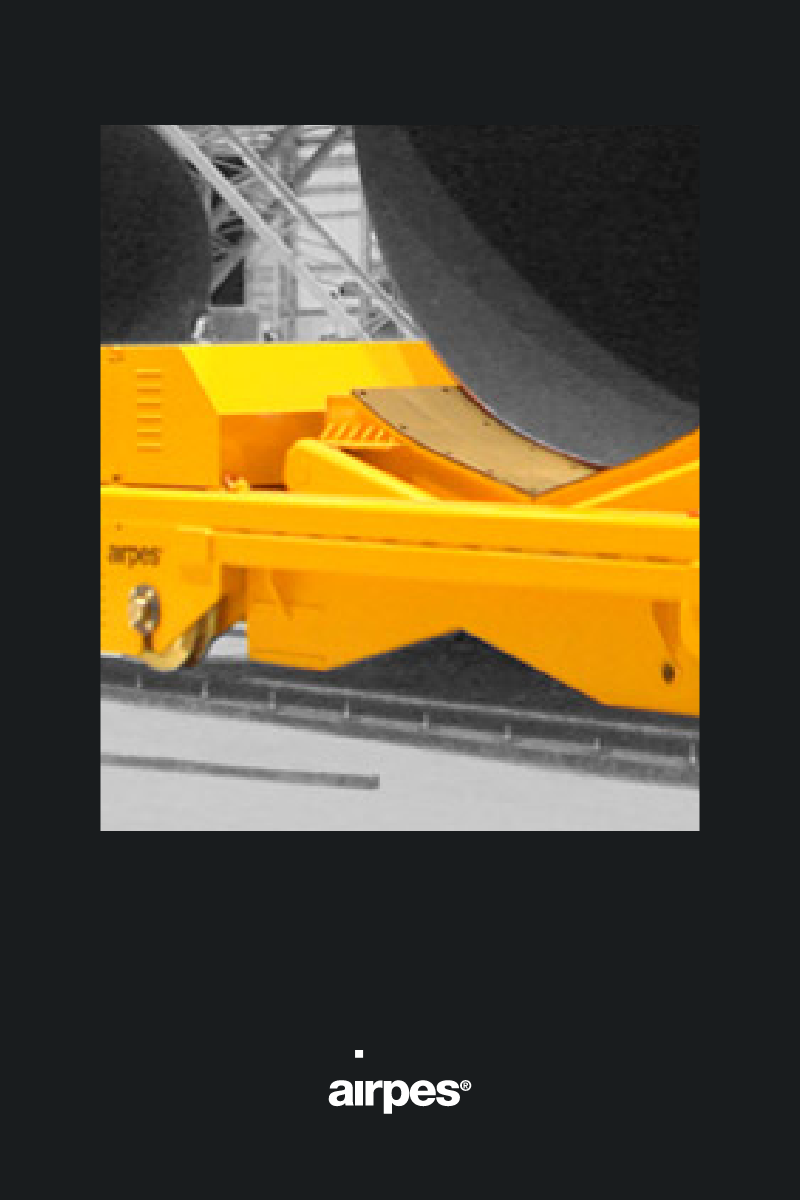

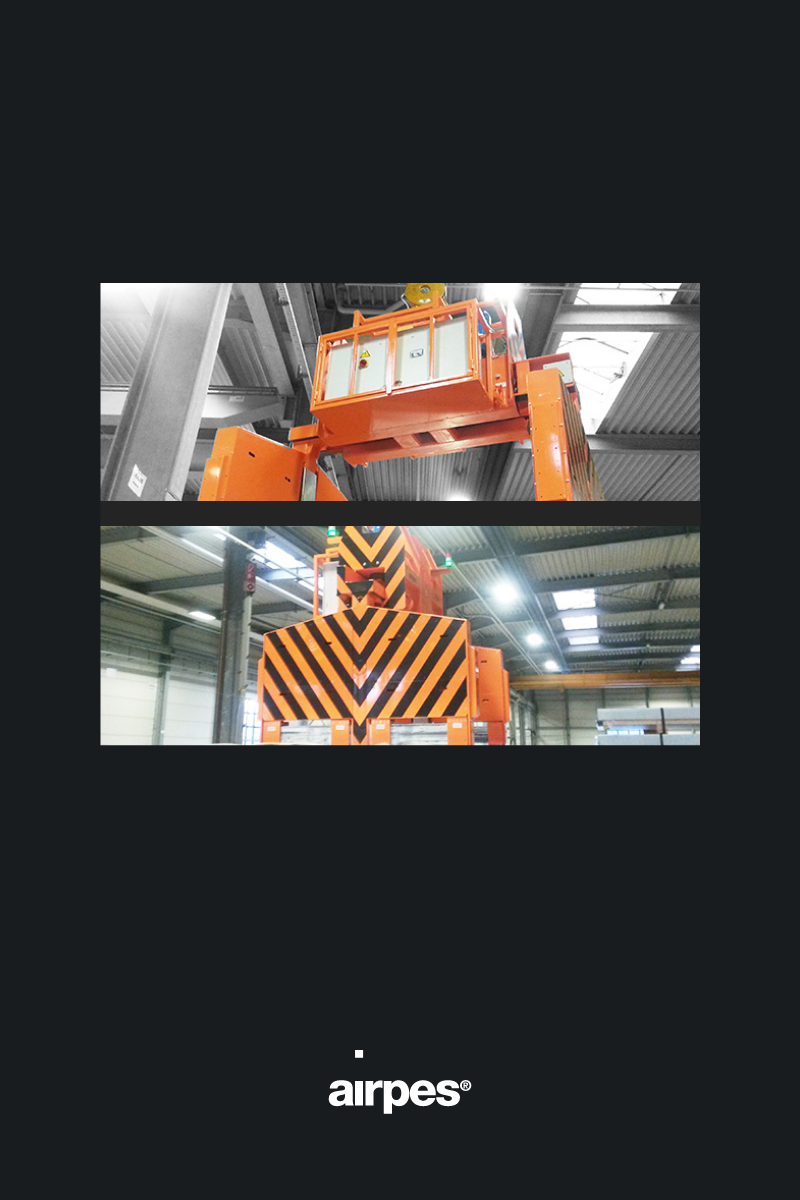

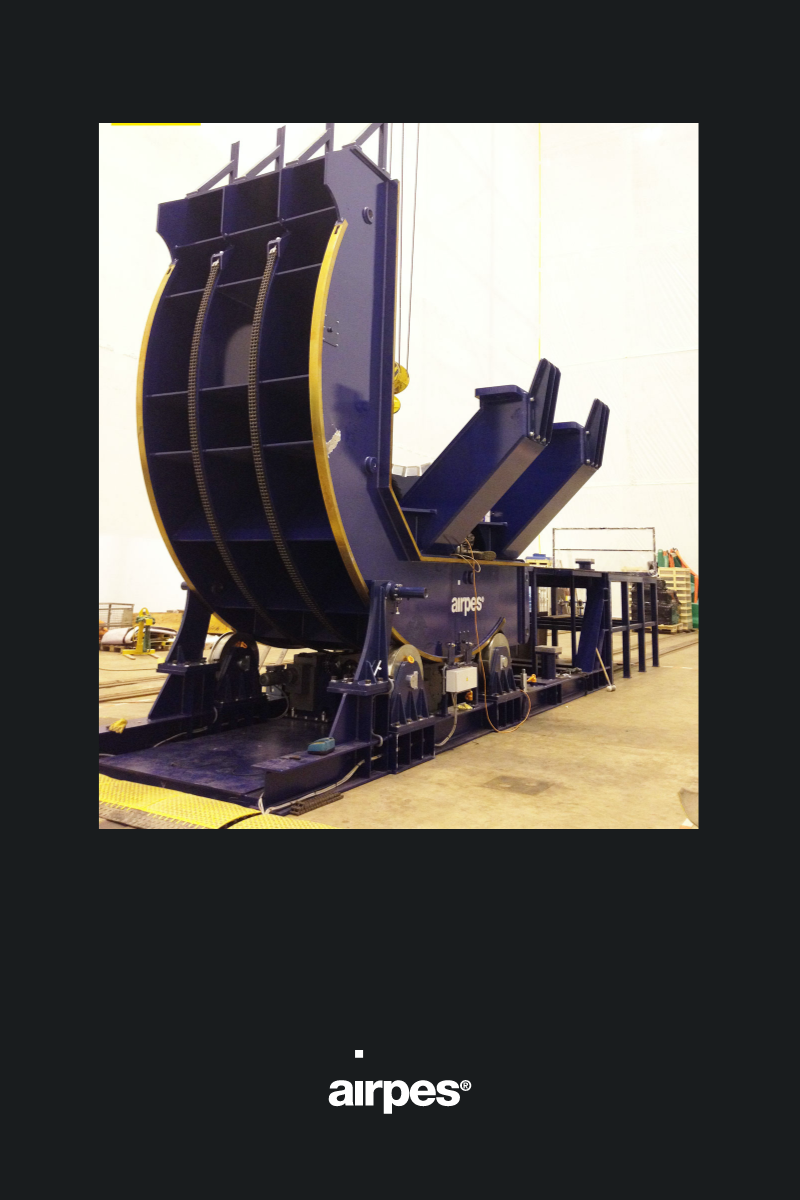

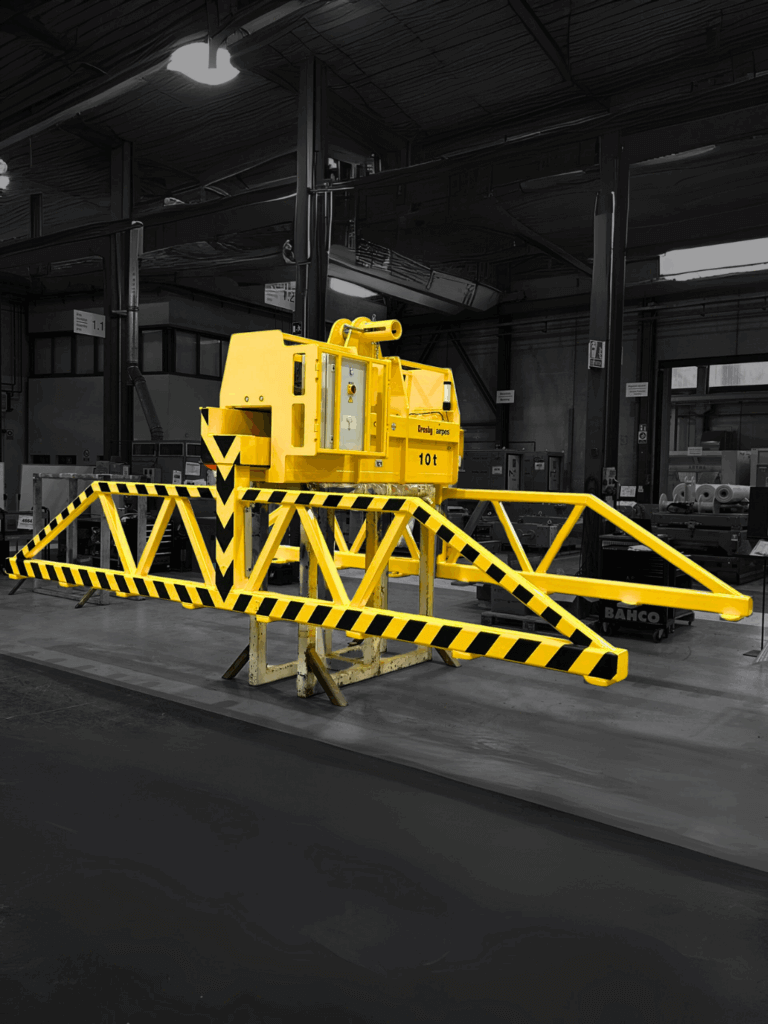

Discover how Crosby Airpes designed a custom sheet metal package tong 10T, fully adapted to the most demanding industrial requirements.

Handling heavy sheet metal safely and efficiently

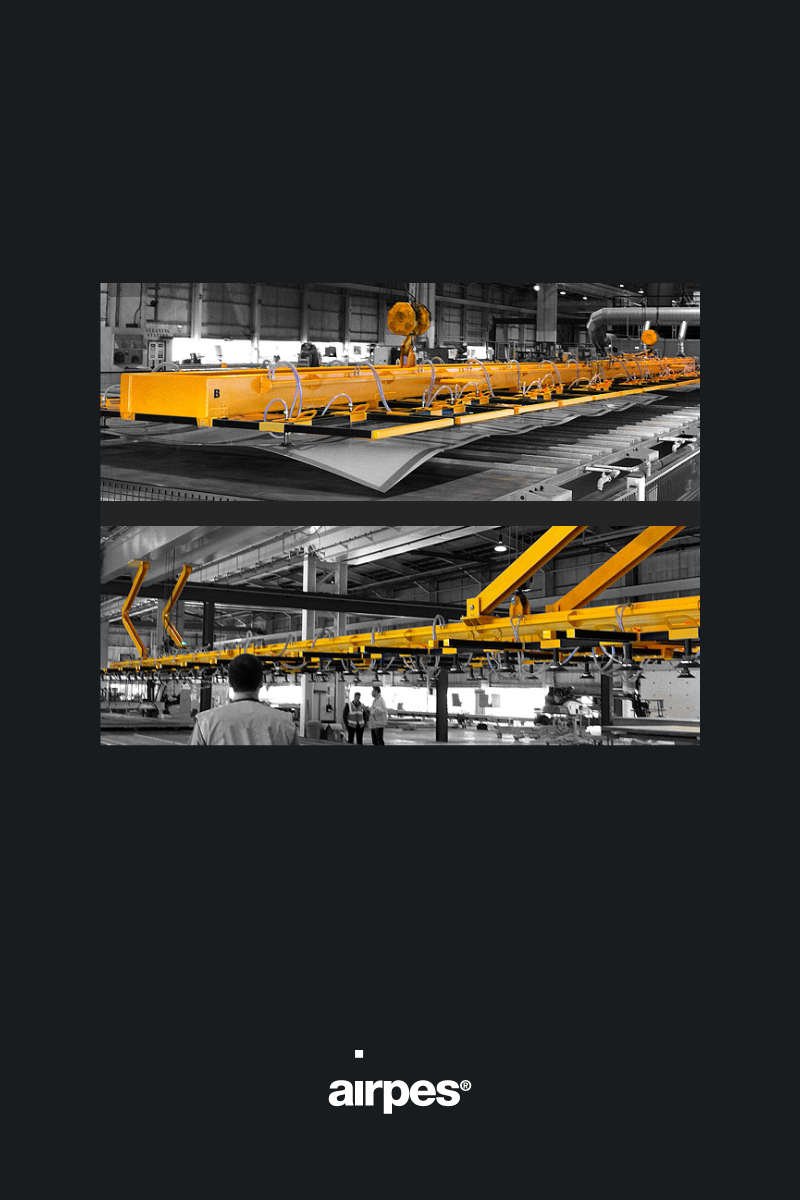

Our client needed to move large-dimensions steel sheet packages weighing up to 10 tons, with variable widths and lengths, and under multiple environmental conditions.

- A secure grip with controlled pressure

- Smooth motorized closing

- Adaptability to a wide range of formats

- Compliance with international safety standards

Safety: a non-negotiable requirement

Given the size and weight of the packages, plus operational speed and human safety concerns, the project demanded a high-performance, tailormade tong system to ensure zero compromise between security and productivity.

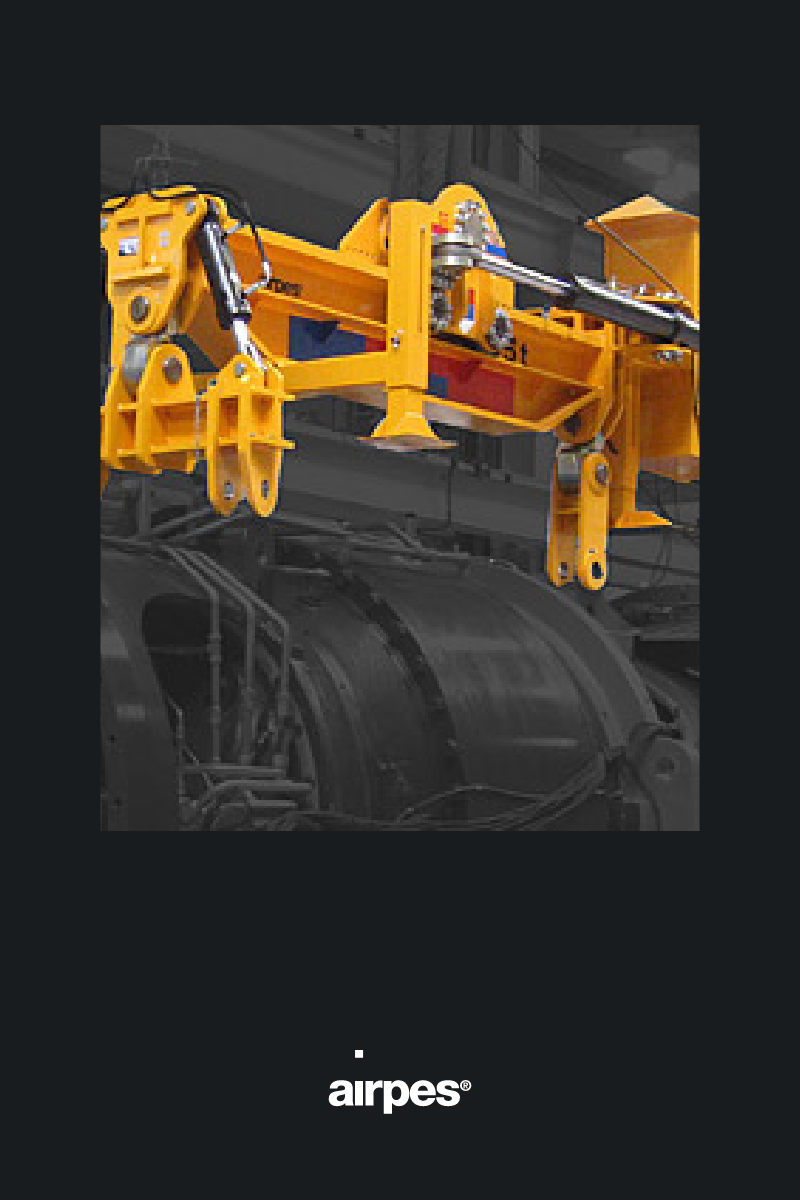

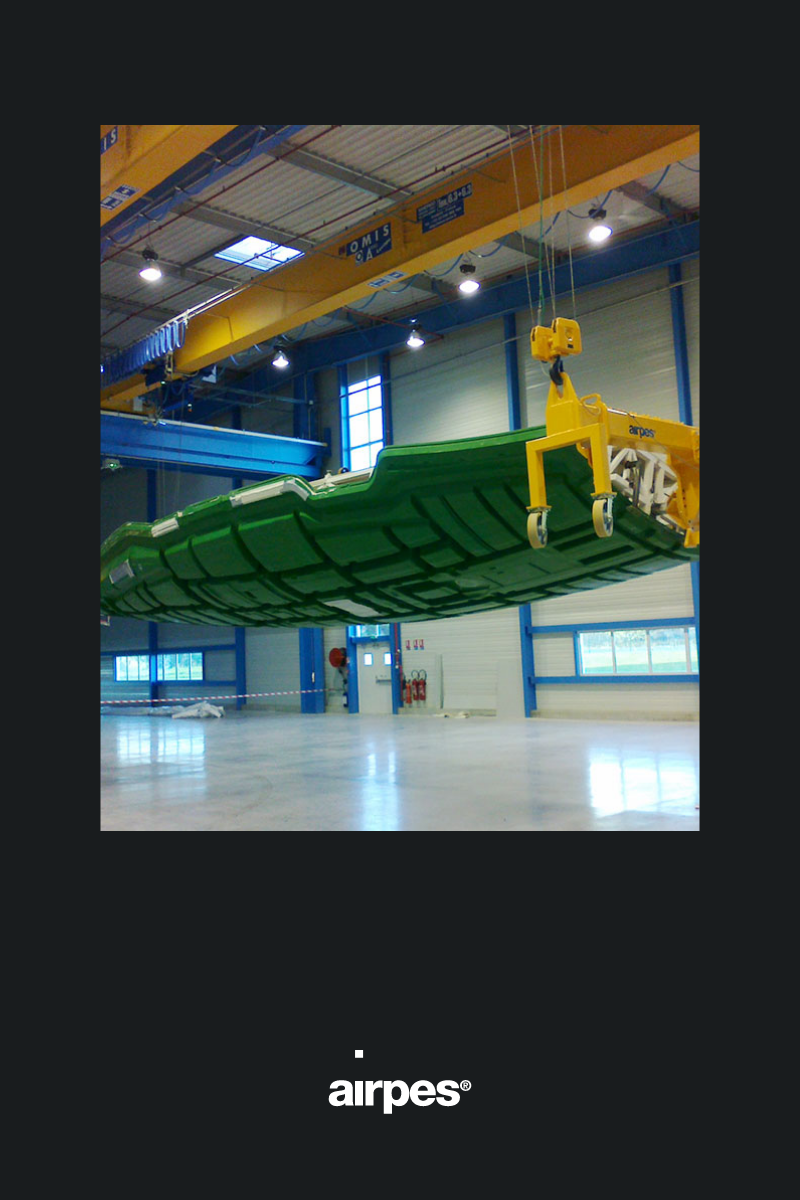

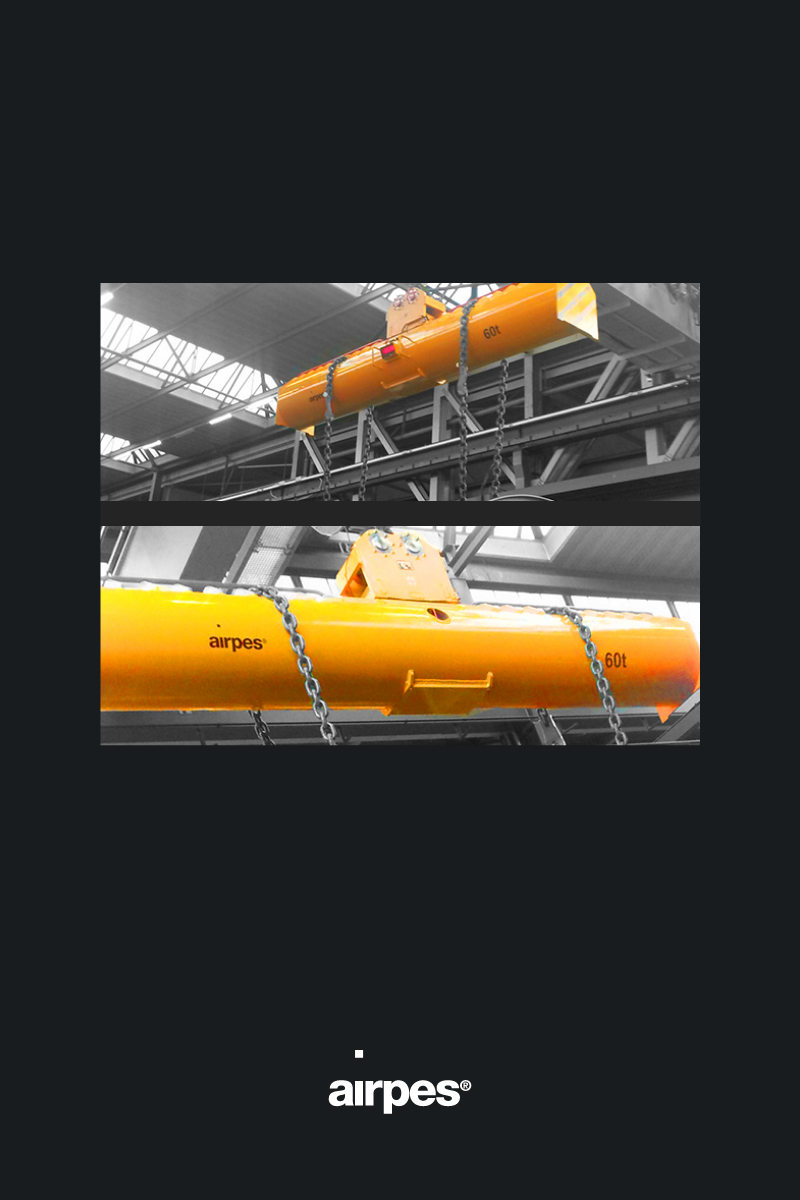

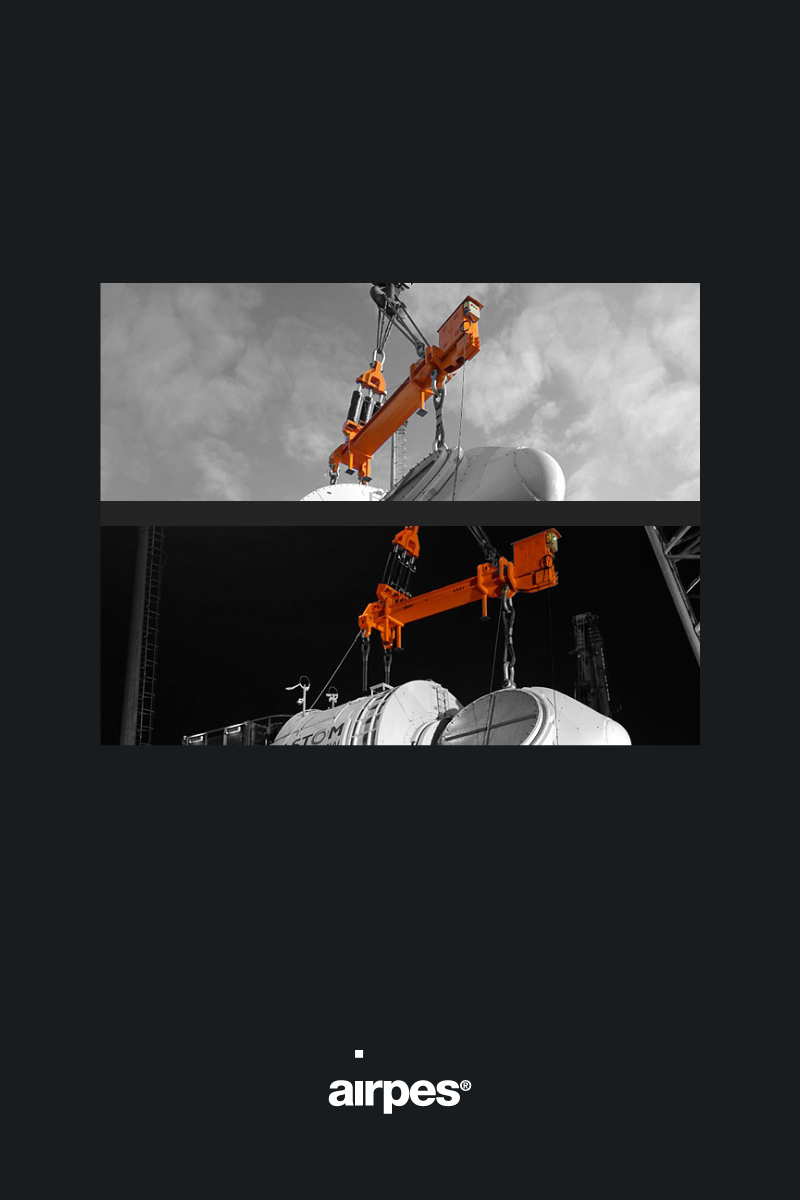

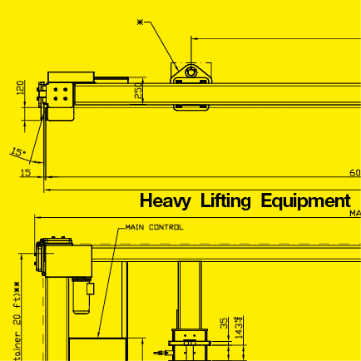

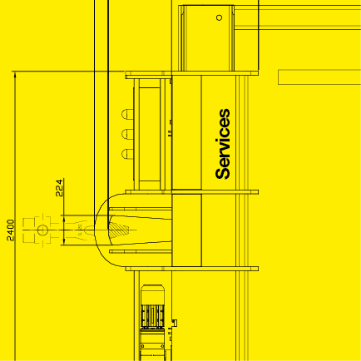

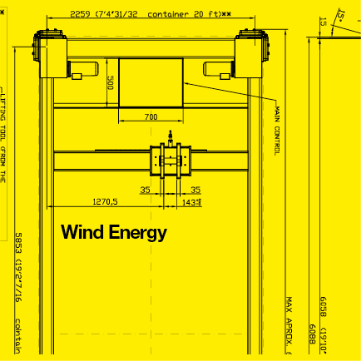

We delivered a custom-engineered heavy duty sheet metal tong—powered, sensor-equipped and precision-built to ensure optimal performance. Our tongs sheet metal systems are designed to adapt to different dimensions, weights and formats while maintaining maximum safety and efficiency.

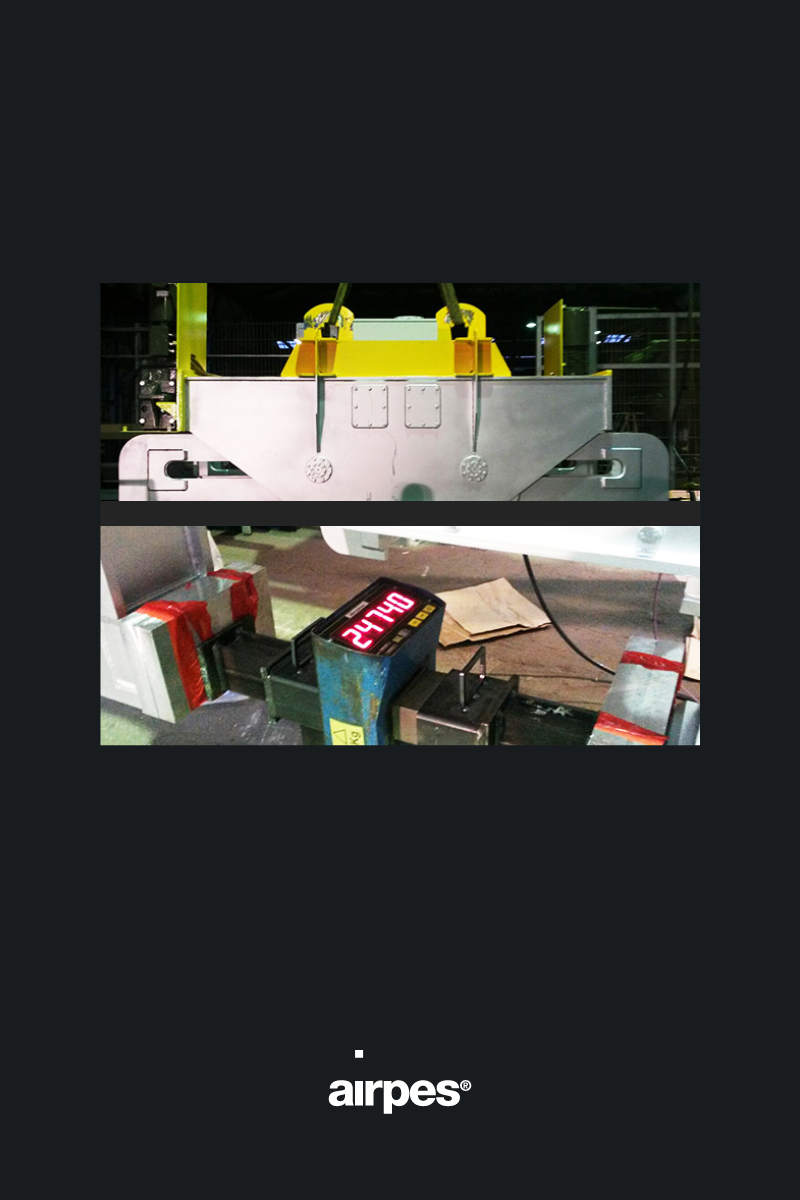

- Capacity: up to 10,000 kg

- Max. width: 1,950 mm | Min. width: 500 mm

- Length: from 1,500 mm to 8,000 mm

- Height: 700 mm

- Operating temp: up to +45°C

- Motor: 460Vac 60Hz

- Leg closing speed: 8 m/min

- Tare weight: approx. 2,900 kg

- Motorized gear system with automatic tong arms

- Hook compliant with DIN 1540 – Nº20

- Dual load sensors and pivot flap sensors

- End limit switches for minimum and maximum openings

- Manual locking system for added safety

- Dual-side lighting for improved visibility

- Centralized electrical box for easy maintenance

All our products comply with the strictest European regulations and are certified by:

- ISO 9001:2015 (Quality Management)

- ISO 14001:2015 (Environmental Management)

- ISO 45001:2018 (Occupational Health and Safety)

Our engineering, manufacturing and commercial processes ensure safe lifting solutions that meet the toughest industrial demands.

Efficiency gains for the client

With our sheet metal tong 10T, the client benefits from:

- Faster handling times

- Reduced manual intervention

- Increased operator safety

- Adaptation to multiple sheet sizes

Even in heavy duty environments, Crosby Airpes tong systems ensures consistency, control and safety.

From concept to commissioning, our sheet metal package tong 10T project is proof of how far custom engineering can go when safety and performance matter most.

Looking for a reliable partner to develop your custom lifting equipment? We design your solution.

- Expert engineering

- Safety-first design

- Industrial-grade components

- Responsive support

With over 260 years of experience, Kito Crosby is the global reference in customized lifting solutions for steel, logistics, energy and more.

1. What is a sheet metal tong used for?

A sheet metal tong is used to safely lift, grip and move large or heavy metal sheets in industrial environments. It applies controlled pressure on both sides of the sheet, allowing operators to handle wide, long or high‑weight formats without damaging the material or risking manual handling injuries.

2. What is the 4T rule for sheet metal?

The 4T rule states that the minimum bend radius of sheet metal should be four times its thickness. This guideline prevents cracking or stress fractures during bending, helping maintain the metal’s structural integrity and ensuring a cleaner, more reliable forming process.

3. What tools do I need for sheet metal?

Sheet metal work typically requires cutting and shaping tools such as shears, snips, press brakes, rollers and bending jigs. For handling large or heavy sheets, industries also rely on lifting tools like sheet metal tongs or vacuum lifters to ensure safe, precise and efficient movement.

4. How thick can sheet metal be before it’s considered a plate?

Sheet metal is generally defined as material up to about 6 mm (0.25 in) thick; anything thicker is classified as plate. This distinction matters because plate requires different cutting, forming and lifting equipment due to its greater rigidity and weight.

5. Can sheet metal tongs be customized for different sizes?

Yes, sheet metal tongs can be custom‑engineered to fit different widths, lengths and load capacities. Custom tongs may include motorized arms, sensors, adjustable openings or reinforced frames, allowing industries to handle specific sheet formats safely and efficiently.

-

MESH NIPPERS

Find out more about Airpes’ Mesh Nippers, our best tool to ensure a perfect and safe lifting for your wire…MESH NIPPERSSeptember 22, 2020 -

Sheet Lifters for Safe and Efficient Steel Plate Handling

At Crosby Airpes, we design and manufacture sheet lifters that guarantee safe, efficient, and precise handling of steel plates and…Sheet Lifters for Safe and Efficient Steel Plate HandlingSeptember 22, 2020

OUR on demand solutions

Airpes Solutions

LATEST POSTS ON THE BLOG

Discover our brand new developments, events, get posted of our activity.

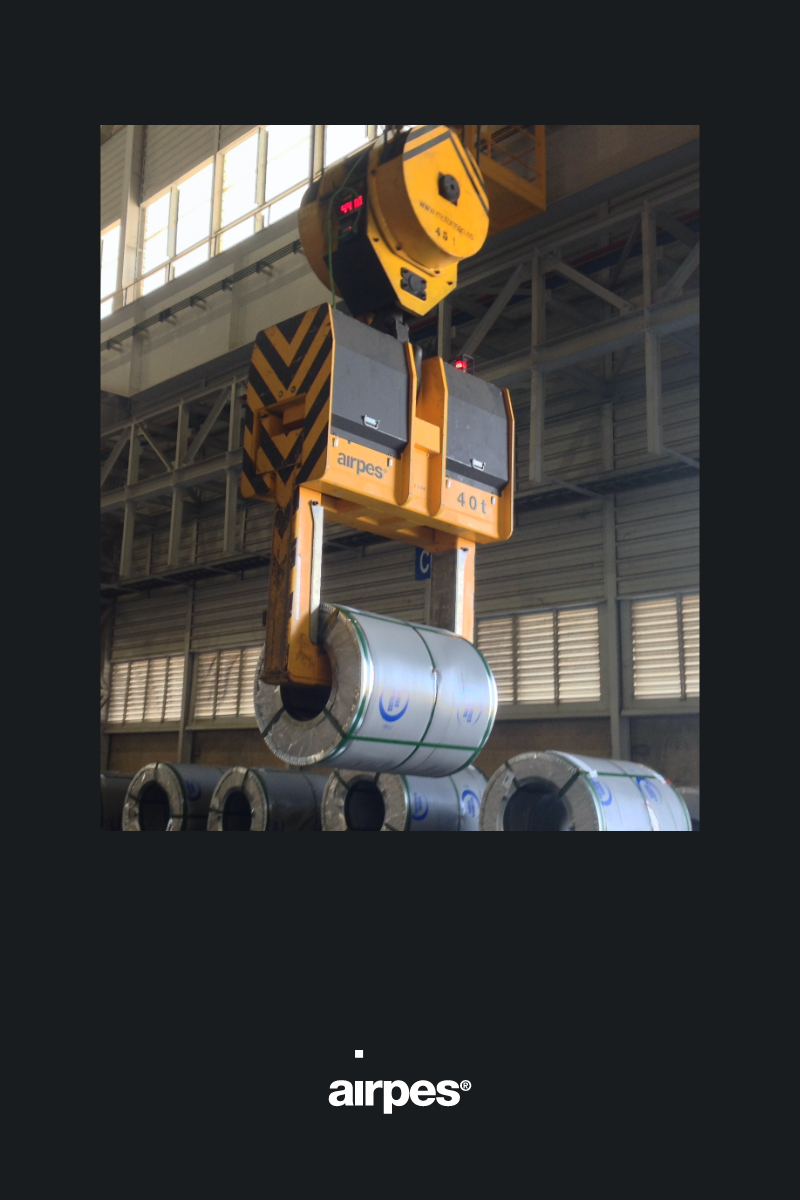

- Coil Transfercar: handle industry coils safelyCoil transfer cars are mobile platforms for the safe transport of industrial coils of any type, size and...

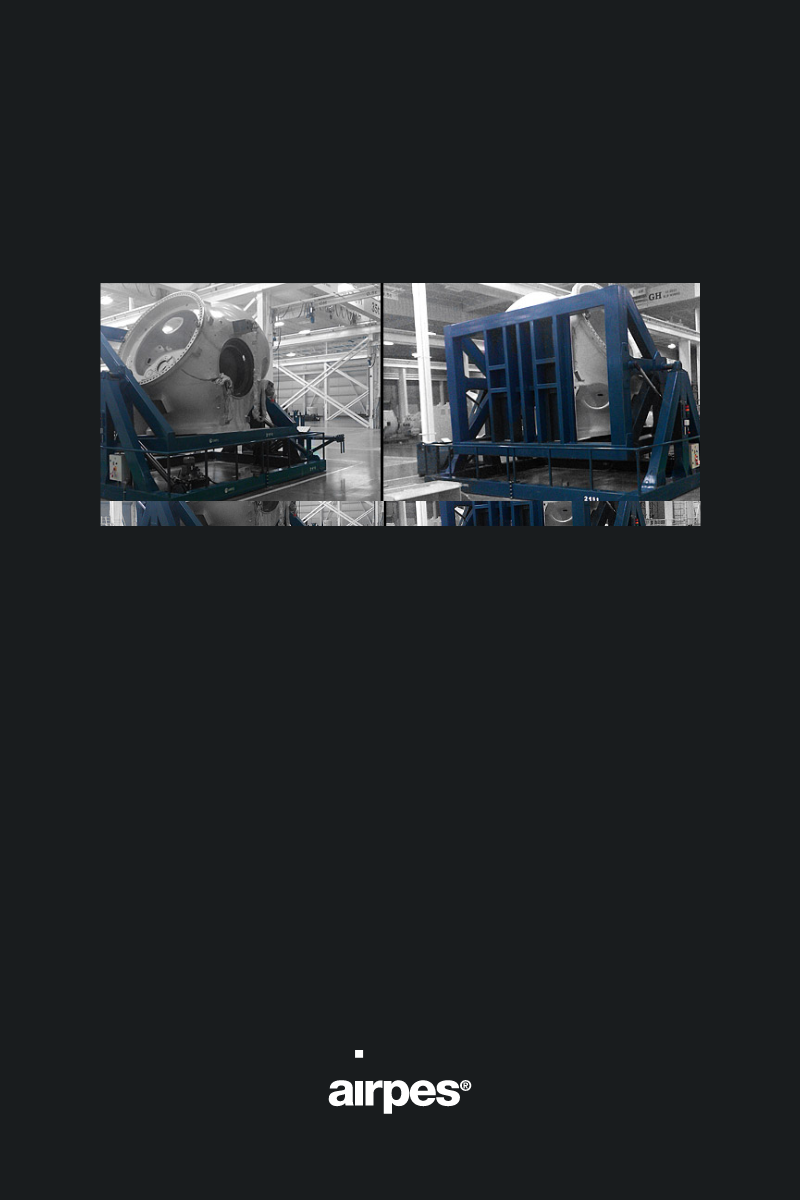

- Industrial Load Turning Devices: how to choose the right solutionNot all heavy loads are the same and not all turning devices should be either. In this guide,...

- Industrial scale safety: essential measures for crane scales and lifting equipmentWe review six safety precautions to keep in mind when using a crane scale to minimize some risks...

- Difference between onshore and offshore wind farmsOnshore and offshore wind energy present similarities and differences. We analyze the challenges involved in working in each...