You can use a crane scale to suspend massive or weighty loads and measure their weight within the workplace. This equipment helps minimize some risks associated with handling heavy loads because it simplifies the process of lifting and weighing and reduces the time spent transporting loads from one place to another to measure them.

Since crane scales help you carry heavy-duty material, you must consider additional safety measures to avoid any accidents regarding personal injury or goods damage. Let’s review six basic safety precautions to keep in mind when using a crane scale.

How to use crane scales safely

1. Ensure your crane scale is installed properly

Before using a crane scale, you must ensure that the equipment has been installed appropriately. The installation must follow the rules and necessities the manufacturer sets out in the relevant handbook and comply with safety measures. A proper installation will avoid problems, malfunctions, or accidents.

2. Only allows your trained workers to be the ones using the crane scale

Only those who are professionally trained can operate crane scales to avoid accidents. Heavy machinery needs knowledge and skills to be used safely, and crane scales are no exception.

3. Train your team in risk prevention

Training in occupational risk prevention is a must in every business, and it’s even more critical in environments where big loads must move around. Ensure your team has the training to keep from suspended loads and know the risks when operations occur.

4. Never pass under a suspended load

You should never go underneath a load suspended during the weighing process. If the load falls, it can cause severe injuries (such as broken bones) and property damage. There can never be enough caution.

5. Never go over the maximum load limit of the scale

To avoid breaking a crane scale, never exceed their maximum load limit. You have to know the exact load limit of your equipment and ensure you never trespass it. To obtain an accurate reading, you must stay within the suitable capacity; otherwise, you may damage the measuring element or the hook. If the hook is damaged, it can cause the load to fall (and consequent injuries and damage).

6. Performs periodic maintenance and inspections of the crane scale

Please ensure your weighing equipment, such as your crane scales, is inspected regularly to check for malfunctions or inaccurate readings. Periodic inspection and maintenance are mandatory to guarantee safety for your team. Moreover, it will be the only way to ensure the weighing data’s accuracy over time.

You may be interested in: The benefits of using a crane scale

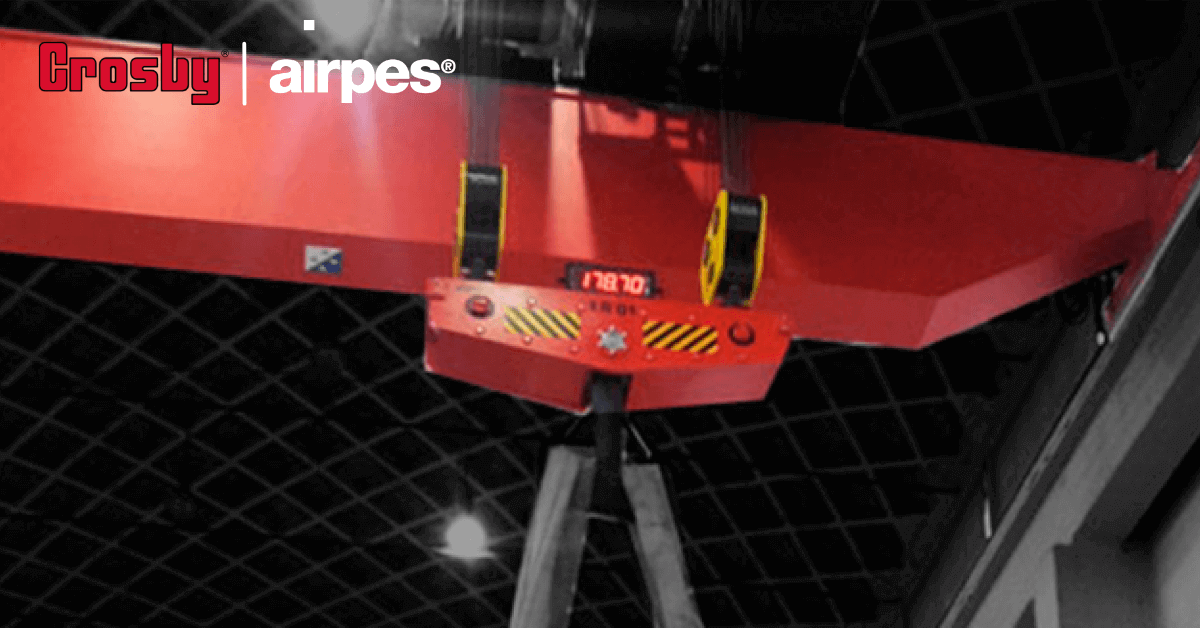

Discover Crosby Airpes crane scale solutions

-

HOOK BLOCK SCALE ATP-100

The ATP hook block scale is an electronic weighing system of great precision, thought to be adapted to any type…HOOK BLOCK SCALE ATP-100November 15, 2020

-

ELECTRONIC CRANE SCALE AGE-120

The AGE-120 electronic crane scale has been designed to be hung up from the hook of the overhead traveling crane,…ELECTRONIC CRANE SCALE AGE-120September 22, 2020

-

ELECTRONIC CRANE SCALE AGM-180

The electronic crane scale AGM-180 has been designed to be hung up from the hook of the overhead traveling crane,…ELECTRONIC CRANE SCALE AGM-180September 22, 2020

Crosby Airpes designs and manufactures on-demand crane scales

¿Do you need a crane scale? We can design and manufacture crane scales to control the entrance and exit of items, storage control, stock control, and other actions.

Our measurement equipment can reset the tare, display the weight in kilograms or pounds, send the weight information via radio, and even use an infrared control system. Calibration is accurate, every single scale is easy to operate, and every model complies with all safety standards.

We can manufacture a new crane scale with a hook from scratch or add a scale to your previous hook. We adapt to your needs.