Handling & engineering project for a UK Manufacturer

Handling & Engineering Project for a UK Producer.

Initial situation description

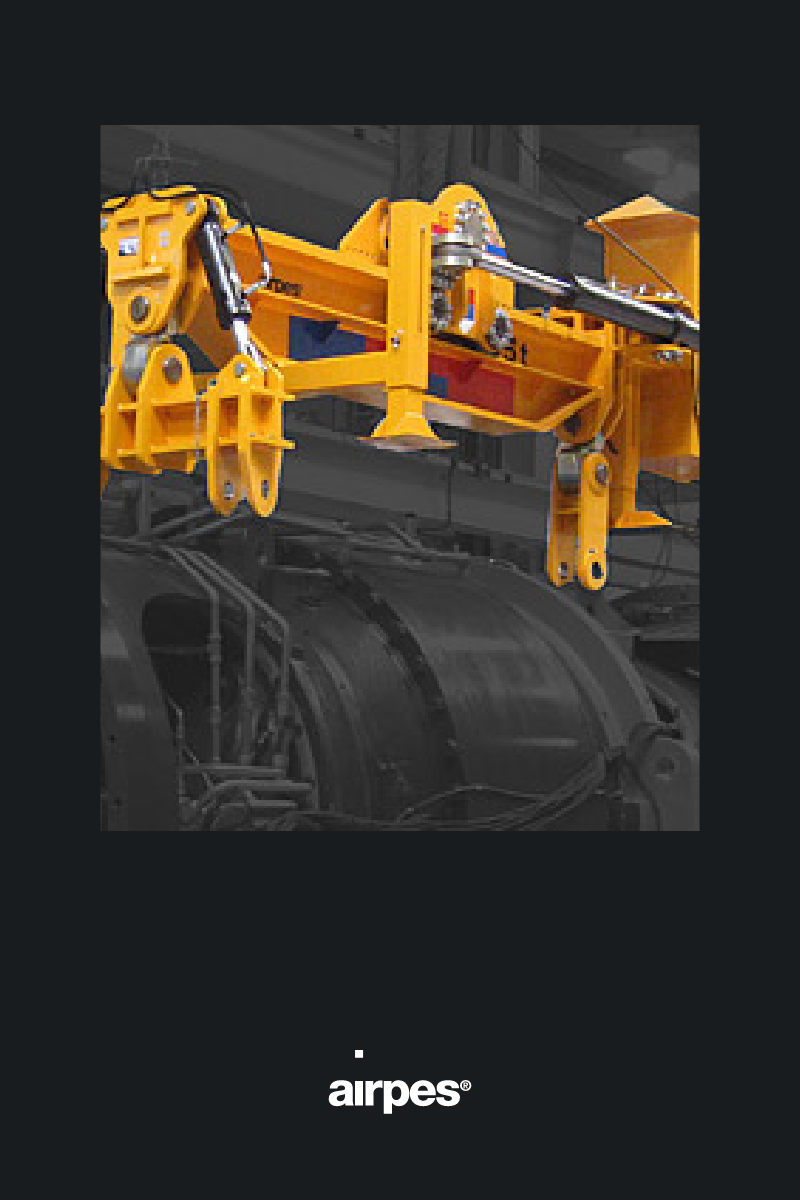

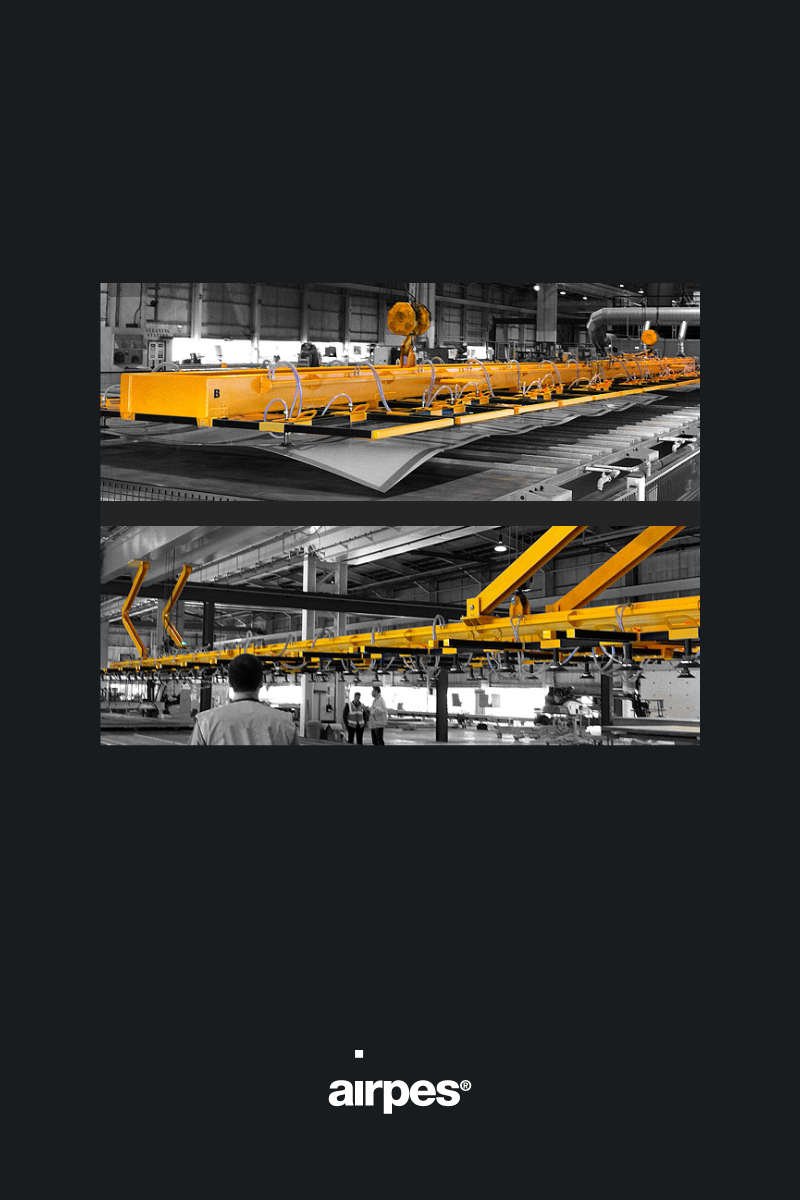

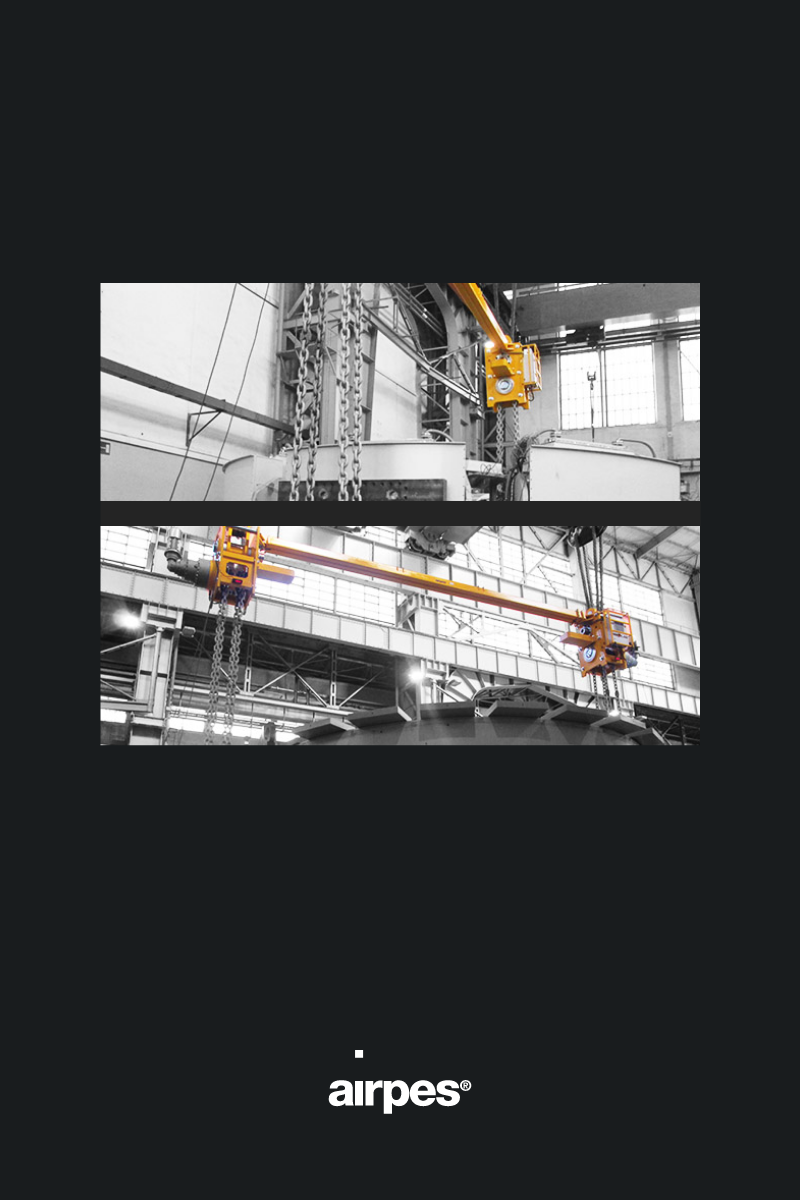

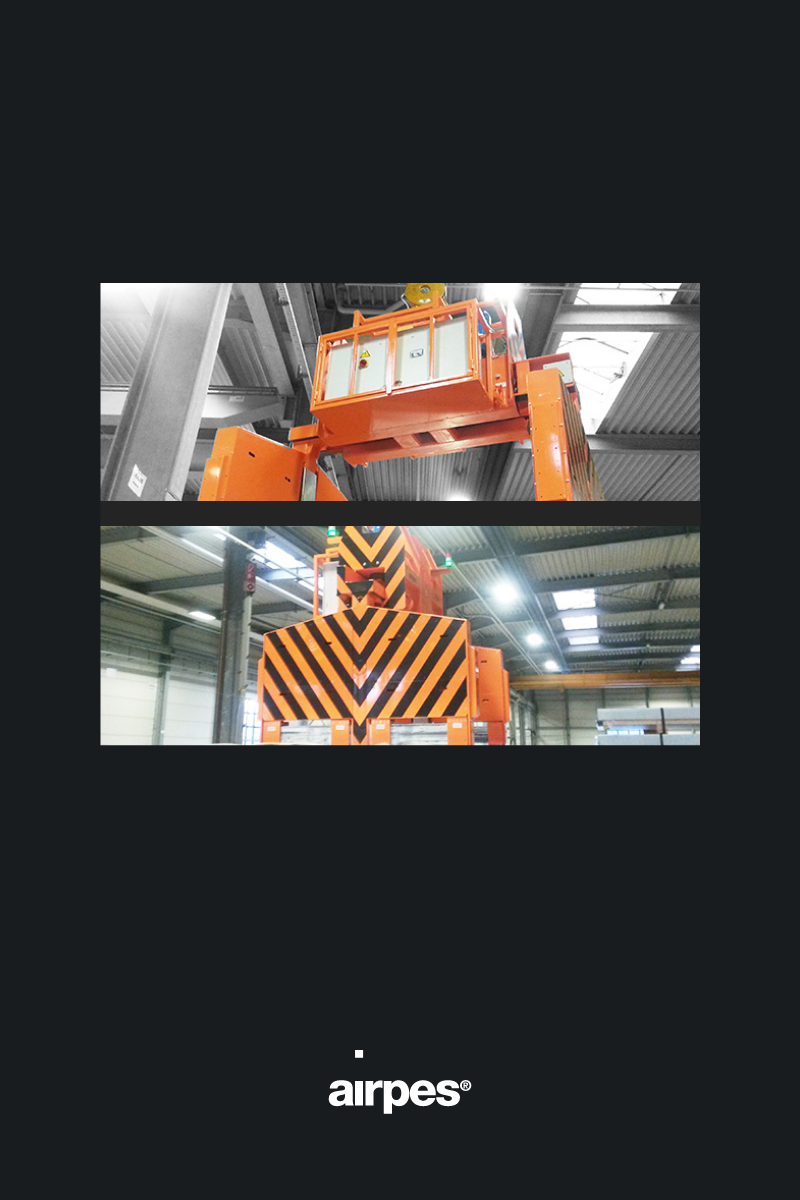

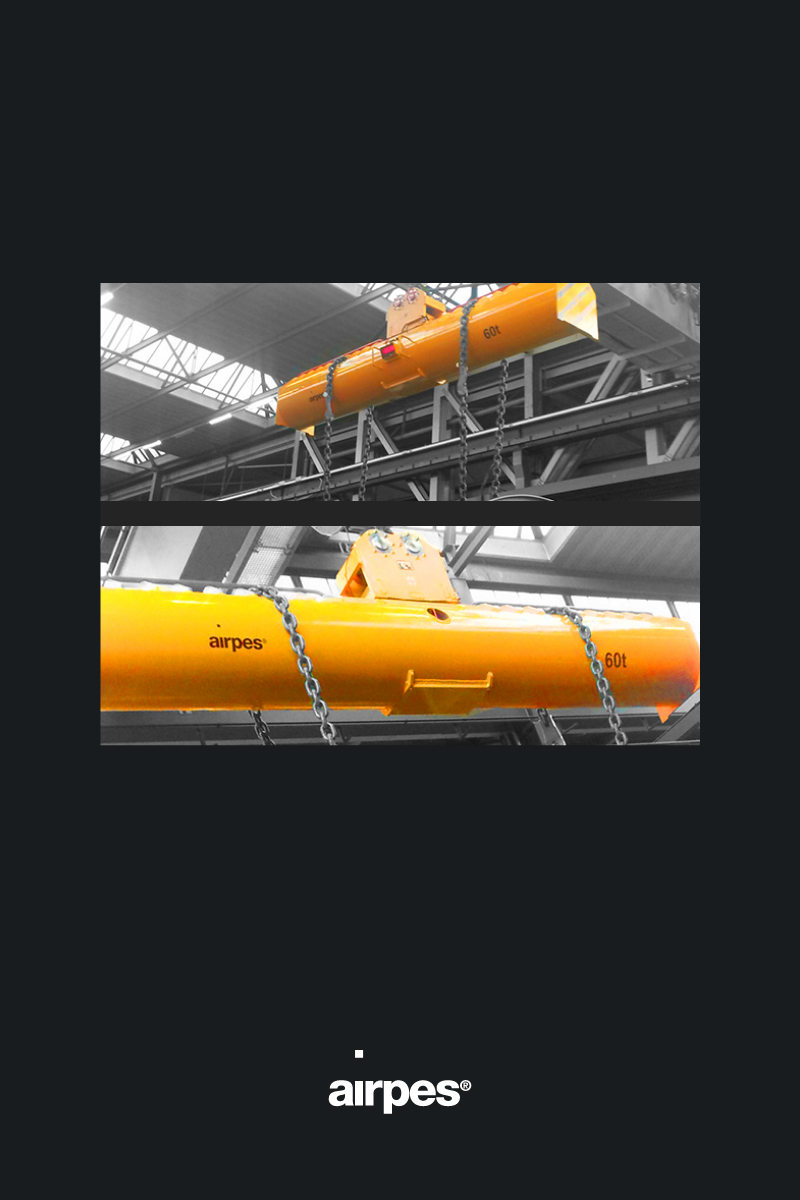

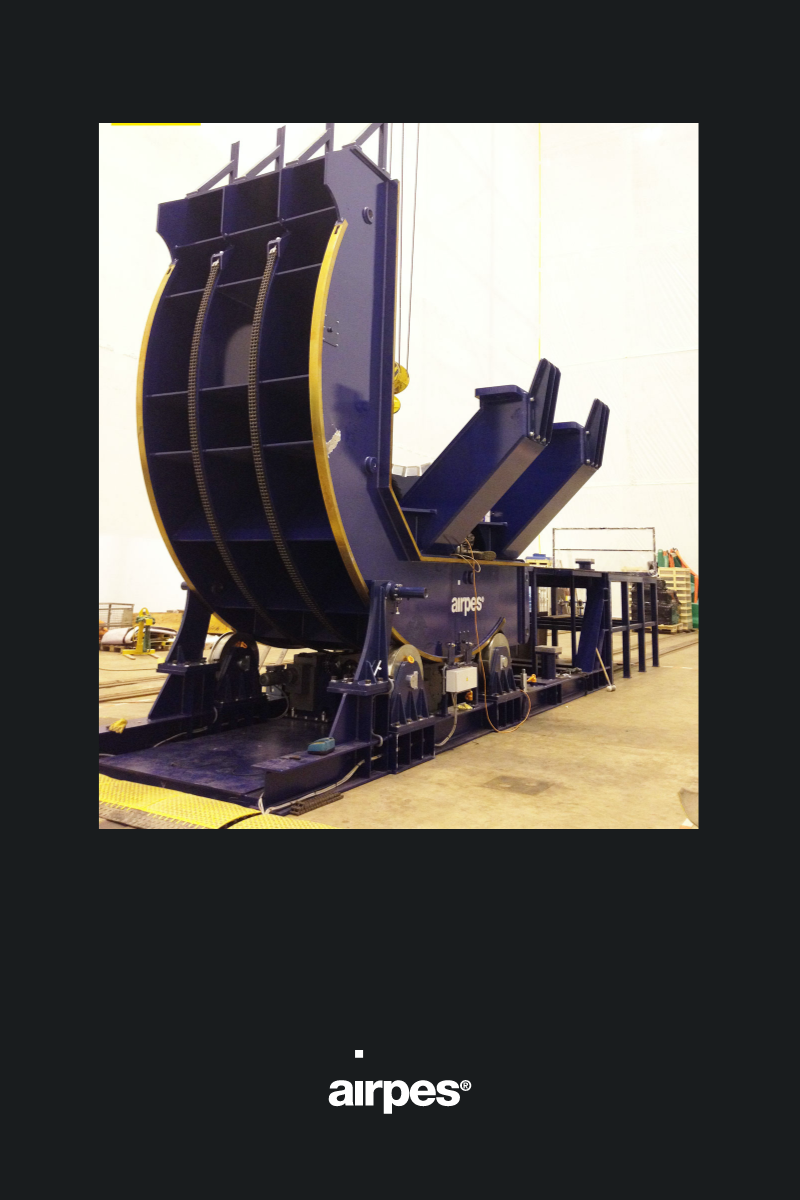

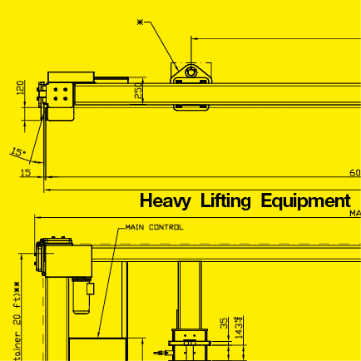

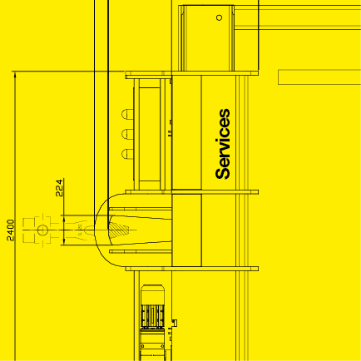

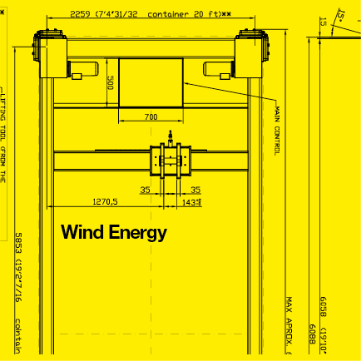

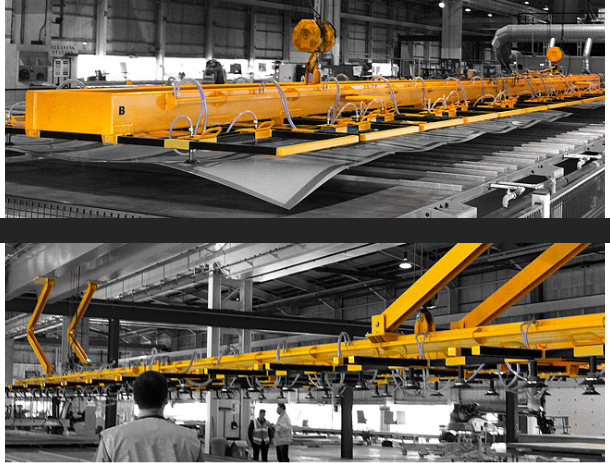

Airpes designed and manufactured 2 beams equipped with vacuum systems composed of 64 suction pads to ensure a correct positioning and grip for a safe transport.

Need to solve

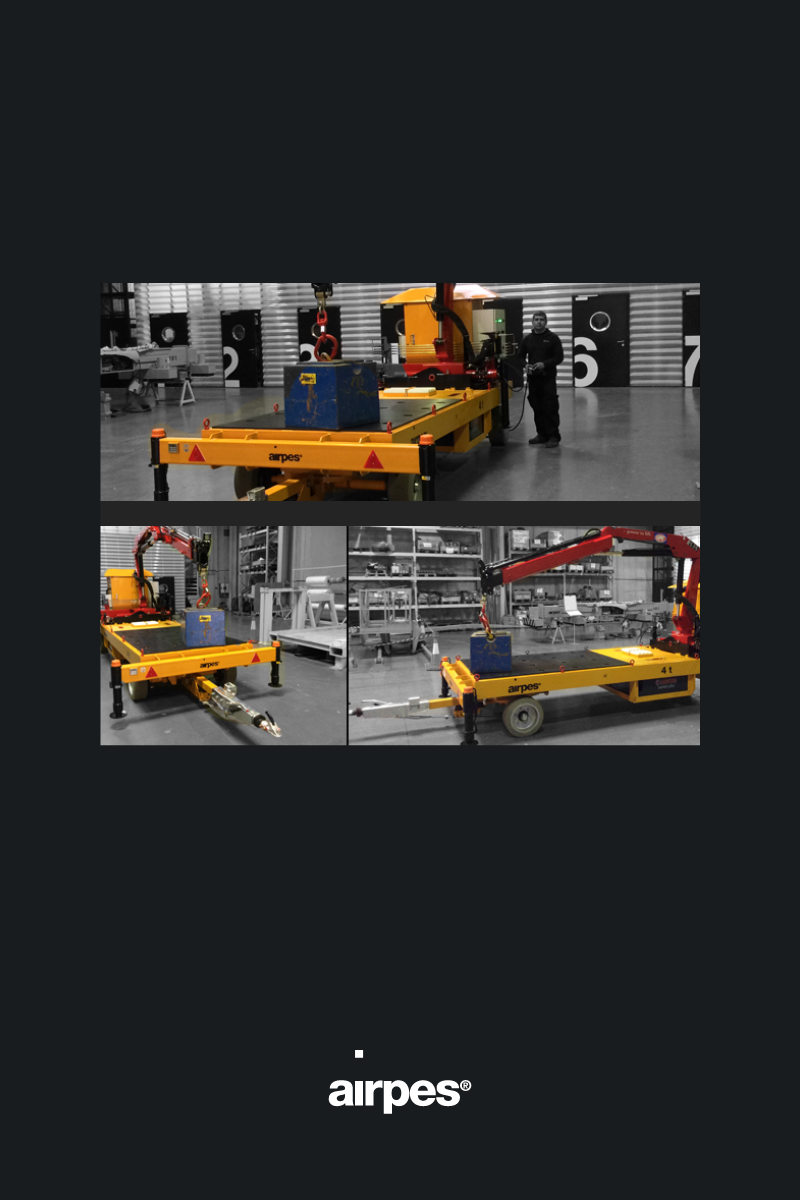

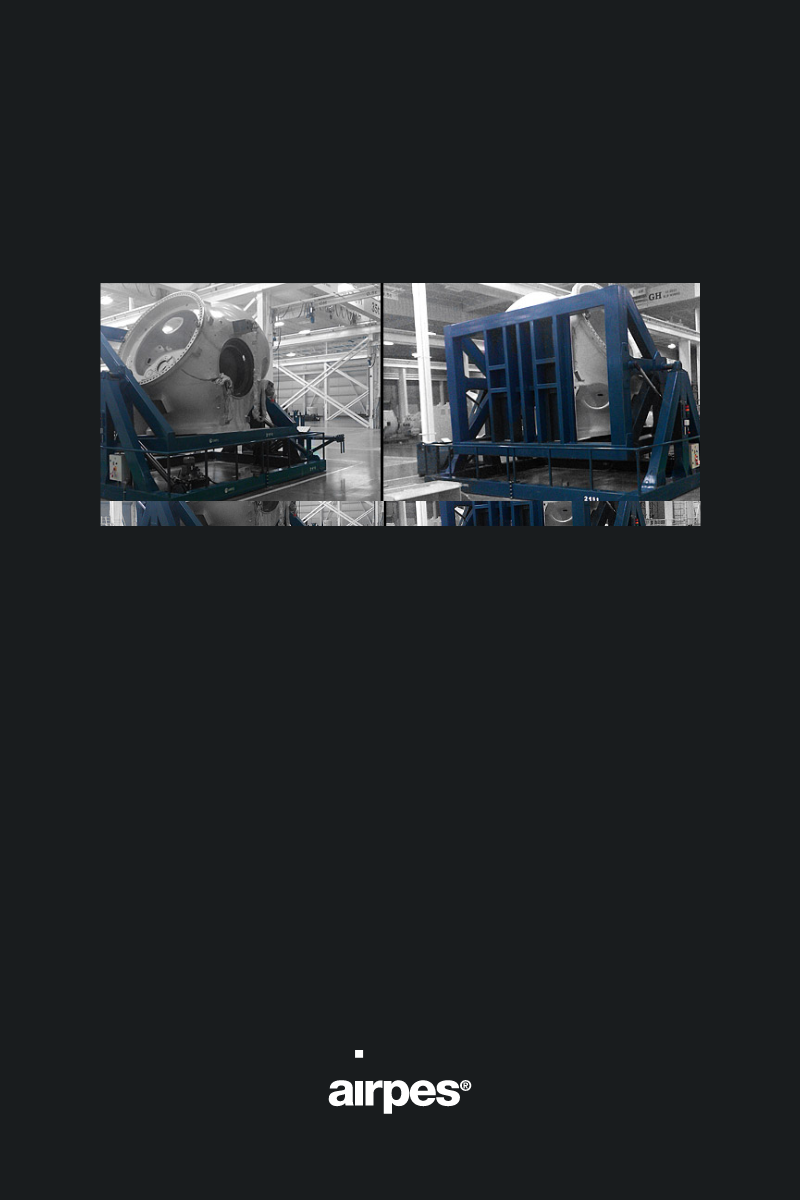

The manufacturer required for this project to improve the handling and transportation of the steel plates assuring safety regulations.

Airpes, as the lifting equipment supplier designed, manufactured and supplied 2 lifting beams equipped with vacuum systems composed of 64 suction pads to ensure correct positioning and grip on the steel plates to safely transport.

The beams also use a sensor based detection protocol to ensure the right position of the steel plates to be transported. Due to the flexibility of the design, the suction pads can be adjusted to follow the shape of the plates.

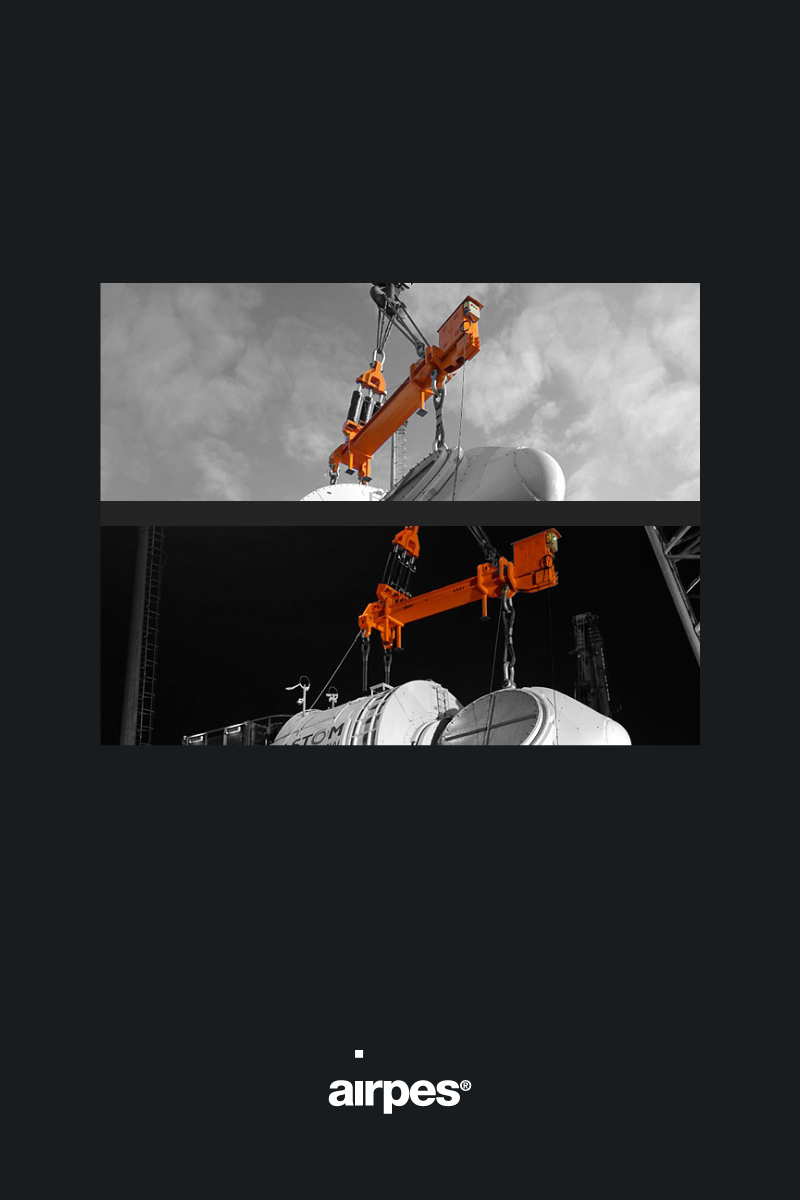

Extreme difficulty with the handling, transportation, and safety of getting the steel plates (up to 19.5m in length) to the presses. Once the steel plates arrived at the presses, placing them on the presses is extremely time consuming.

- Transportation process efficiency increased more than 40% in this phase by now utilizing the suction cups reliability in place of previous method.

- Process now under safety regulation requirements.

OUR on demand solutions

Airpes Solutions

LATEST POSTS ON THE BLOG

Discover our brand new developments, events, get posted of our activity.

- Hoisting Weight LimitersHoisting weight limiters are critical for safe crane operations. Learn how they work, where to use them, and...

- 5S Lean Methodology for Industrial ExcellenceCrosby Airpes applies the 5S methodology internally to enhance safety, efficiency, and product quality. It's a key part...

- Wind Turbine Engineering: excellence in Blade InstallationCrosby Airpes applies the 5S methodology internally to enhance safety, efficiency, and product quality. It's a key part...

- Overhead Crane Parts: Complete Guide to Crane ComponentsHoists, rigging, sensors... What are the different components of an overhead crane? In this post we check it...