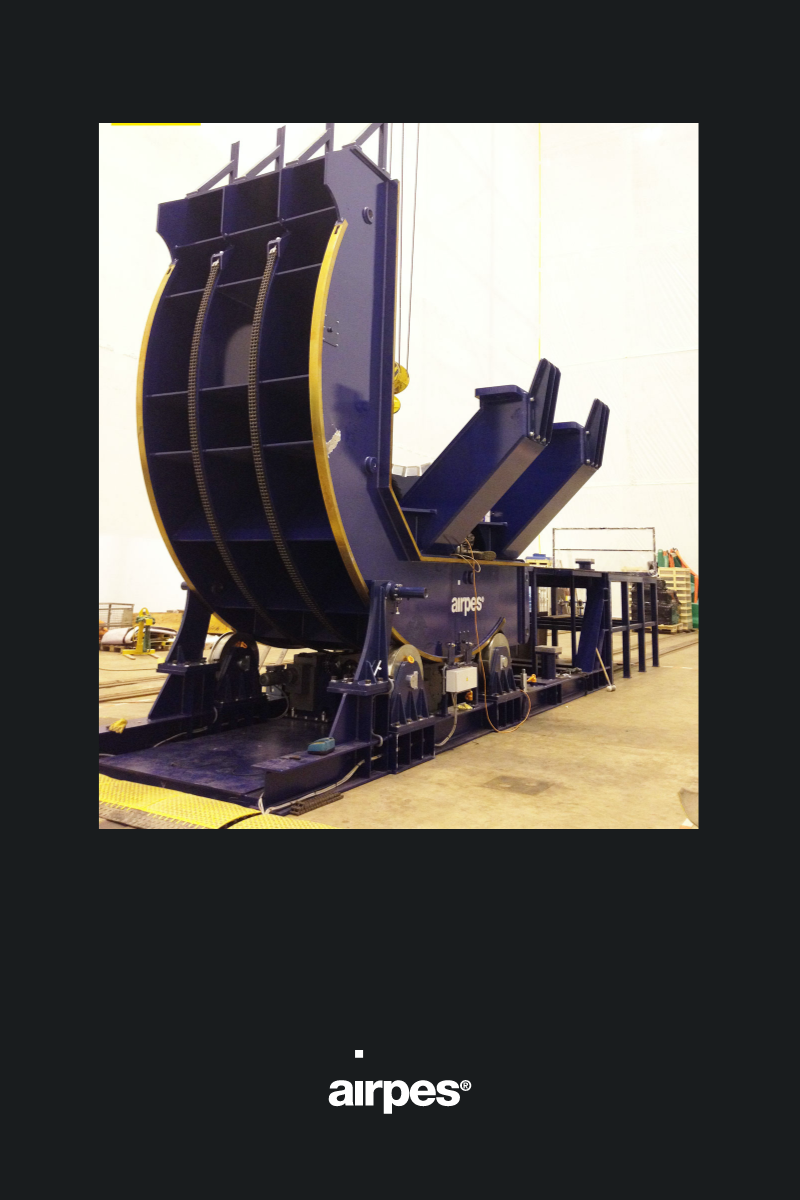

Transport & lifting system with Atex protection for Repsol

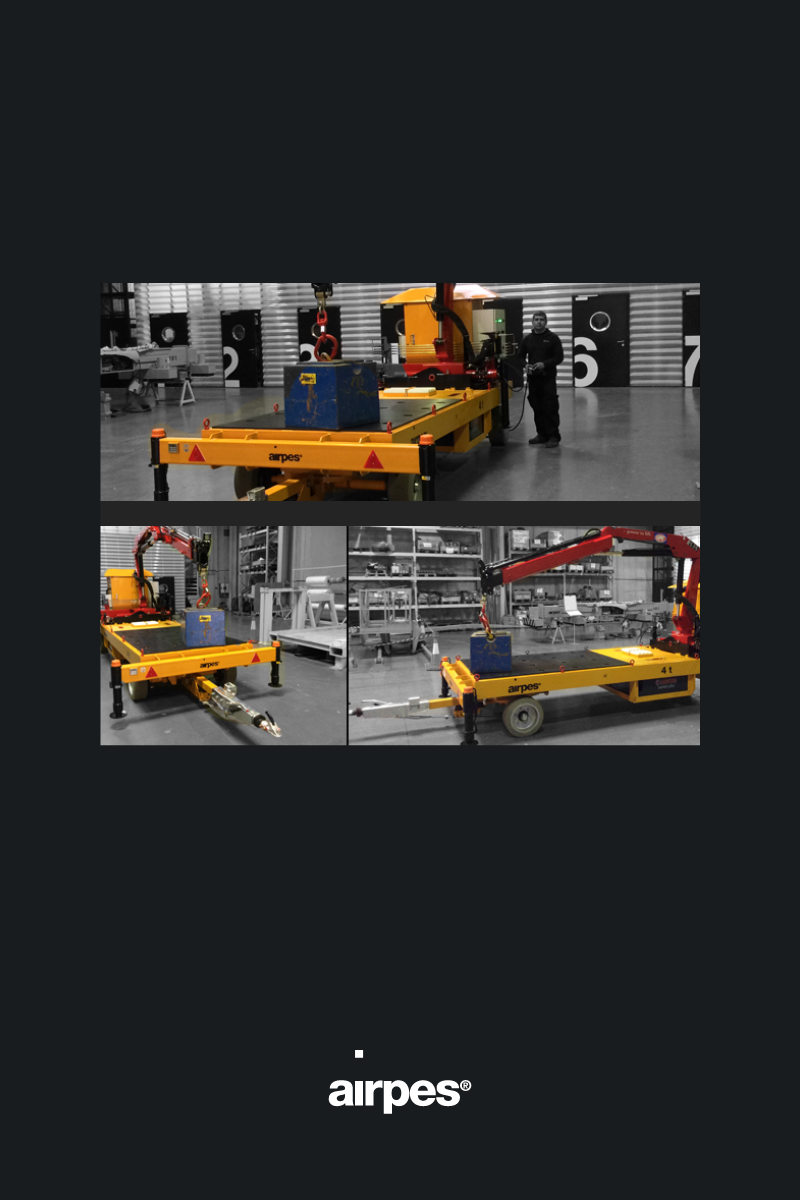

Repsol required a load lifting and transporting equipment up to 4 t. to operate inside its refinery facility located in Cartagena (Spain). It is a high explosive risk area.

Repsol, the customer, requires a load lifting and transporting equipment up to 4 t. to operate inside its refinery facility located in Cartagena (Spain). This is a high explosive risk area and also there are large distances between work areas inside the plant itself.

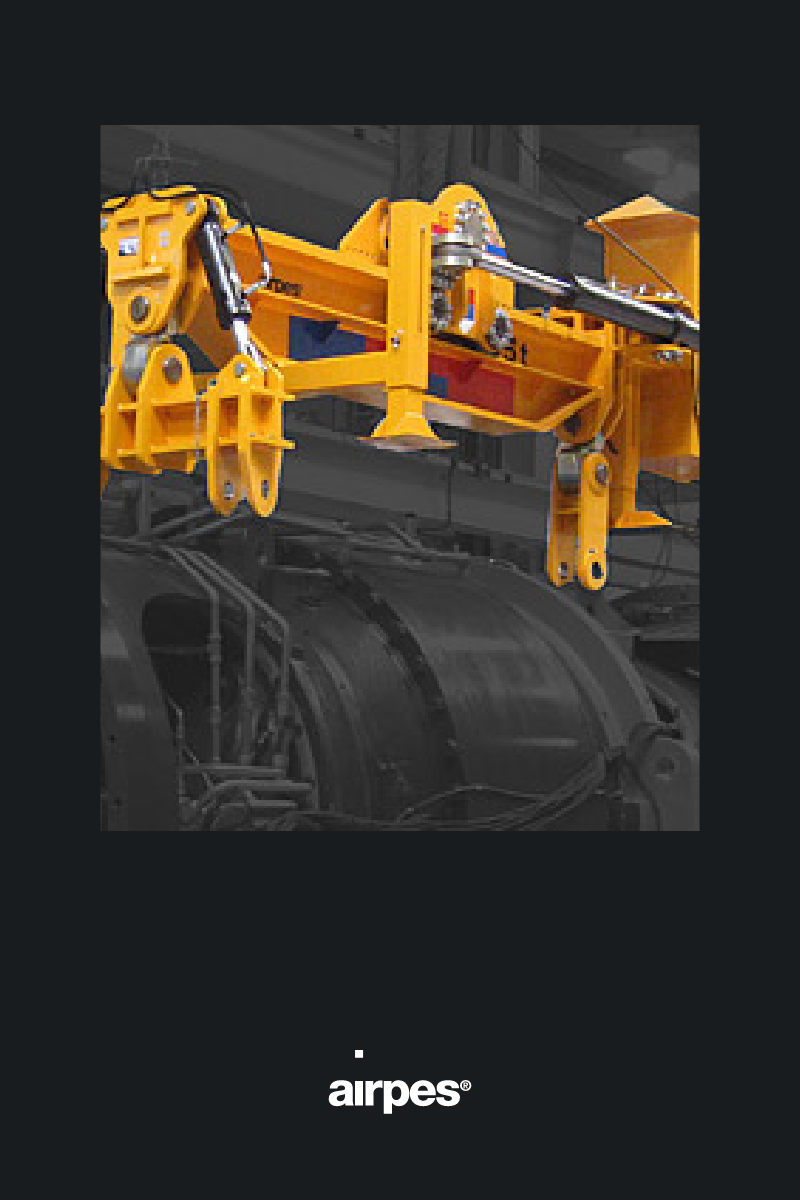

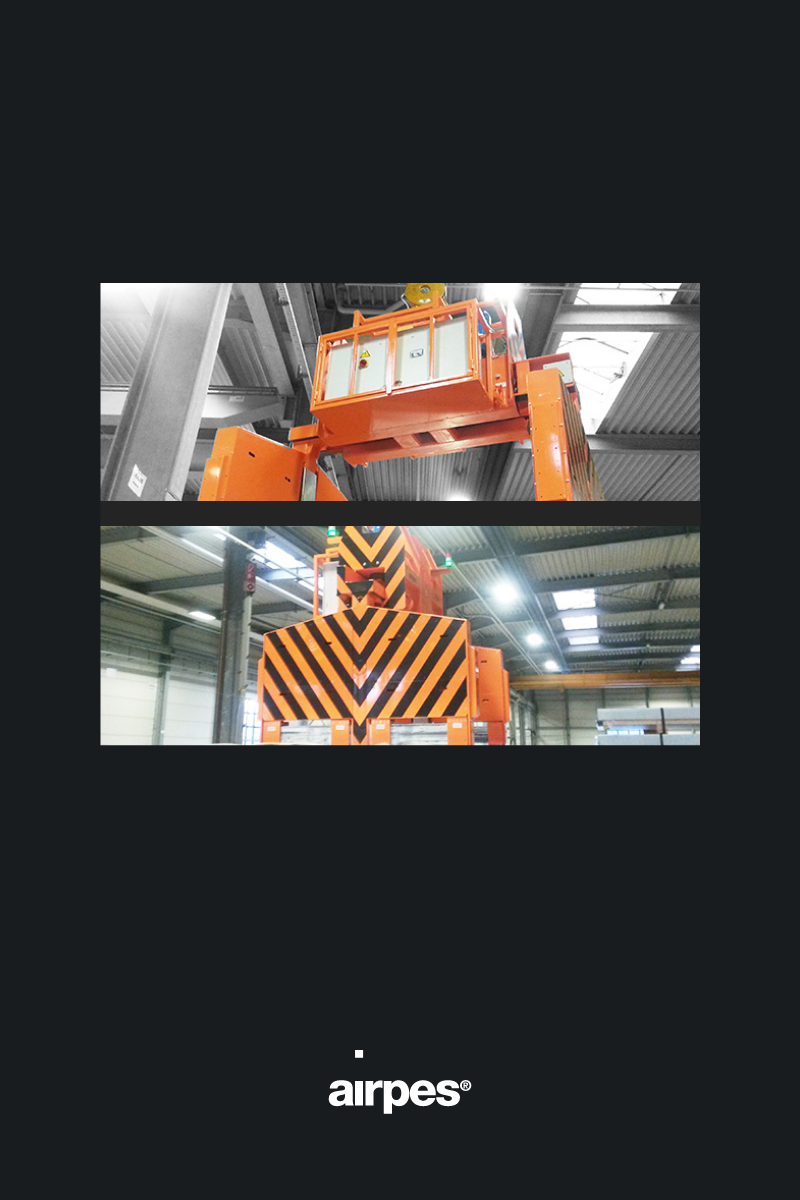

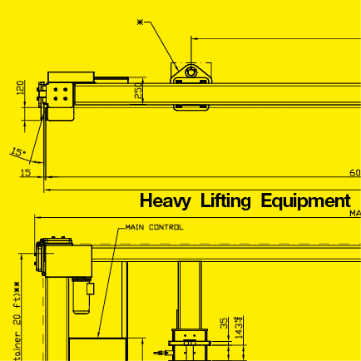

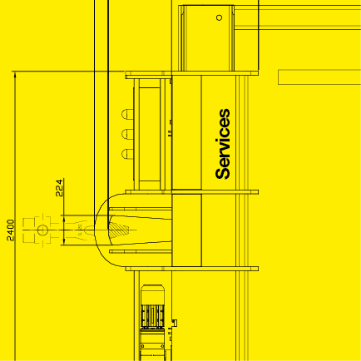

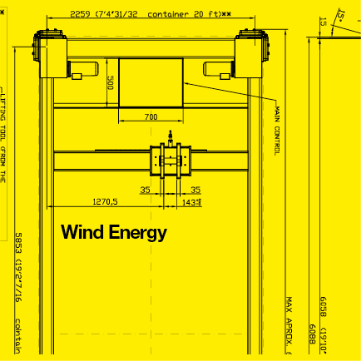

A stand-alone cart with a crane with a telescopic boom installed on board. The power supply must be through batteries, also, a latch system will be equipped to free the turning and convection drives so it can be used as a trailer. This way, it can move throughout the plant extension without risk of depletting batteries.

Stand-alone cart with a crane with a telescopic boom. Battery powered. The cart meets the requirements set by the established policy for areas with potentially explosive atmosferes (ATEX Policy, see the identifying symbol, image1). The carrier operates in a refinery inside potentially explosive areas. These areas are classified as Zone I, Class I, IIB Group, T3.

OUR on demand solutions

Airpes Solutions

LATEST POSTS ON THE BLOG

Discover our brand new developments, events, get posted of our activity.

- Types of lifting hooksChoosing the type of lifting hooks that will help you in your work can be a difficult task....

- Types of lifting tongsDiscover how Crosby Airpes' lifting tongs design is made to safely grab and lift various materials and objects...

- Lifting tongs design: the most precise toolDiscover how Crosby Airpes' lifting tongs design is made to safely grab and lift various materials and objects...

- Benefits of adjustable lifting beams to your businessAdjustable lifting beams offer versatile solutions for various load sizes and shapes, reducing the need for multiple beams,...