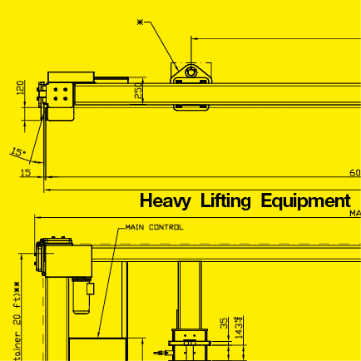

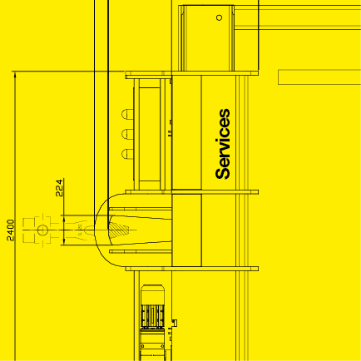

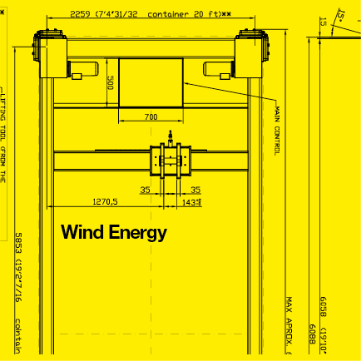

We design and manufacture tailor-made solutions for singular lifting and transportation tasks of the wind energy industry. We also deliver and maintain the equipment. We develop each of our projects to meet the specific needs of our clients.

Airpes solutions cover all stages of an offshore or onshore wind energy project, from initial specifications to training on-site.

We have been working in the wind industry since 2003. We develop each project with the same dedication and methodology. There is just one difference between projects: the number of qualified people involved along the time.

That philosophy lets us reduce the cost of every project without decreasing quality.

Airpes’ objective is to achieve a complete integration of all activities related to manufacturing equipment. That is how we reduce development time and increase the performance and reliability of our solutions for the wind energy industry.

wind industry solution deployment

Airpes Solutions

LATEST POSTS ON THE BLOG

Discover our brand new developments, events, get posted of our activity.

- Hoisting Weight LimitersHoisting weight limiters are critical for safe crane operations. Learn how they work, where to use them, and...

- 5S Lean Methodology for Industrial ExcellenceCrosby Airpes applies the 5S methodology internally to enhance safety, efficiency, and product quality. It's a key part...

- Wind Turbine Engineering: excellence in Blade InstallationCrosby Airpes applies the 5S methodology internally to enhance safety, efficiency, and product quality. It's a key part...

- Overhead Crane Parts: Complete Guide to Crane ComponentsHoists, rigging, sensors... What are the different components of an overhead crane? In this post we check it...