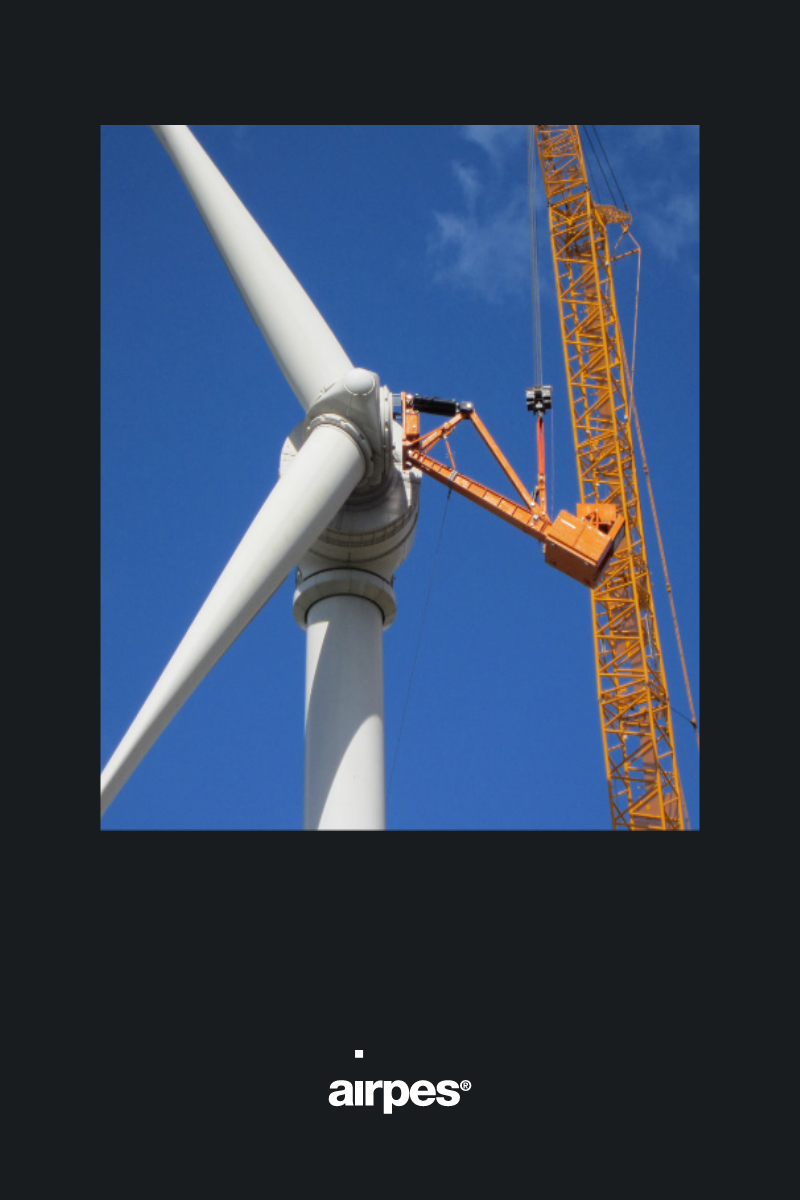

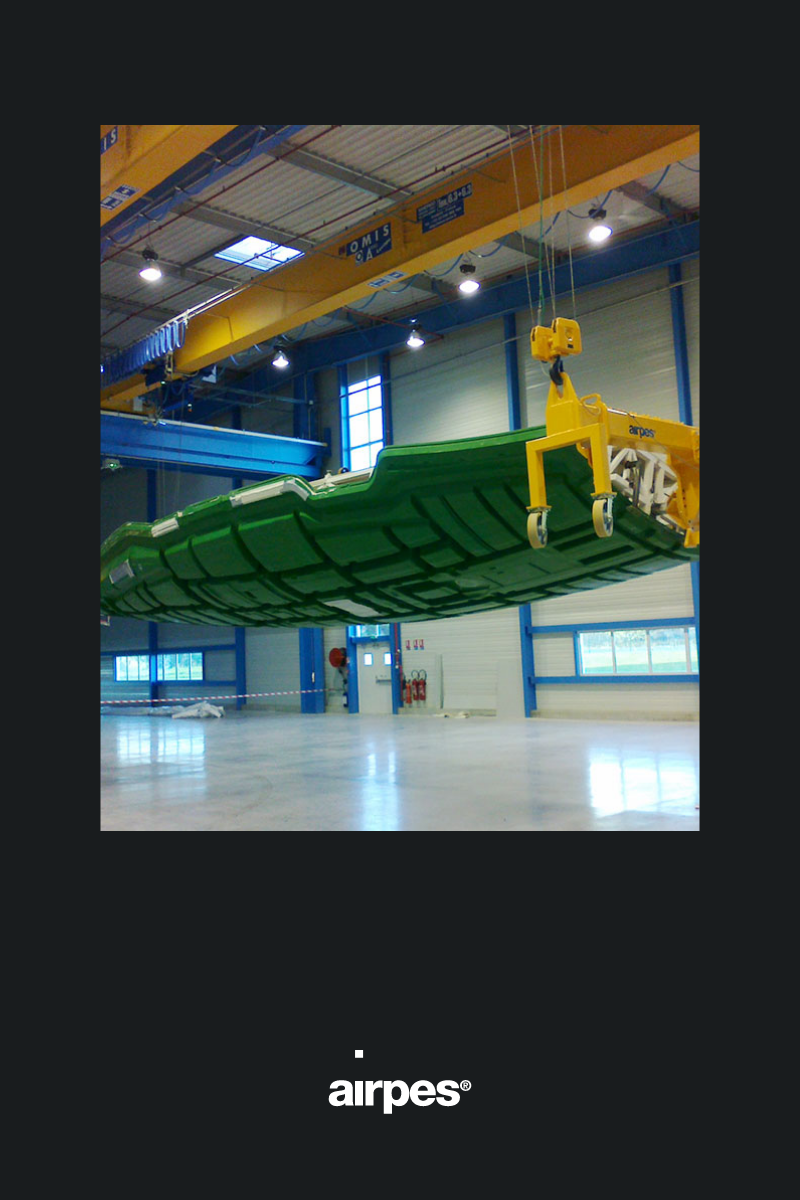

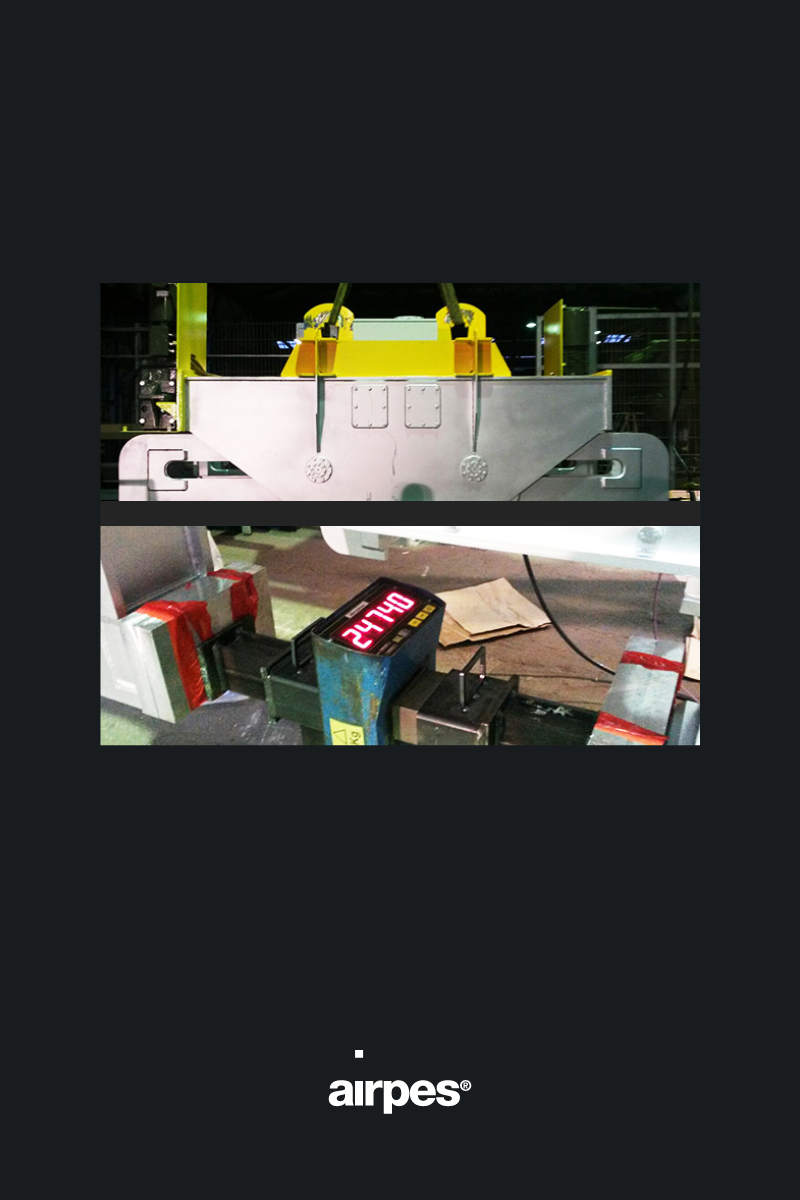

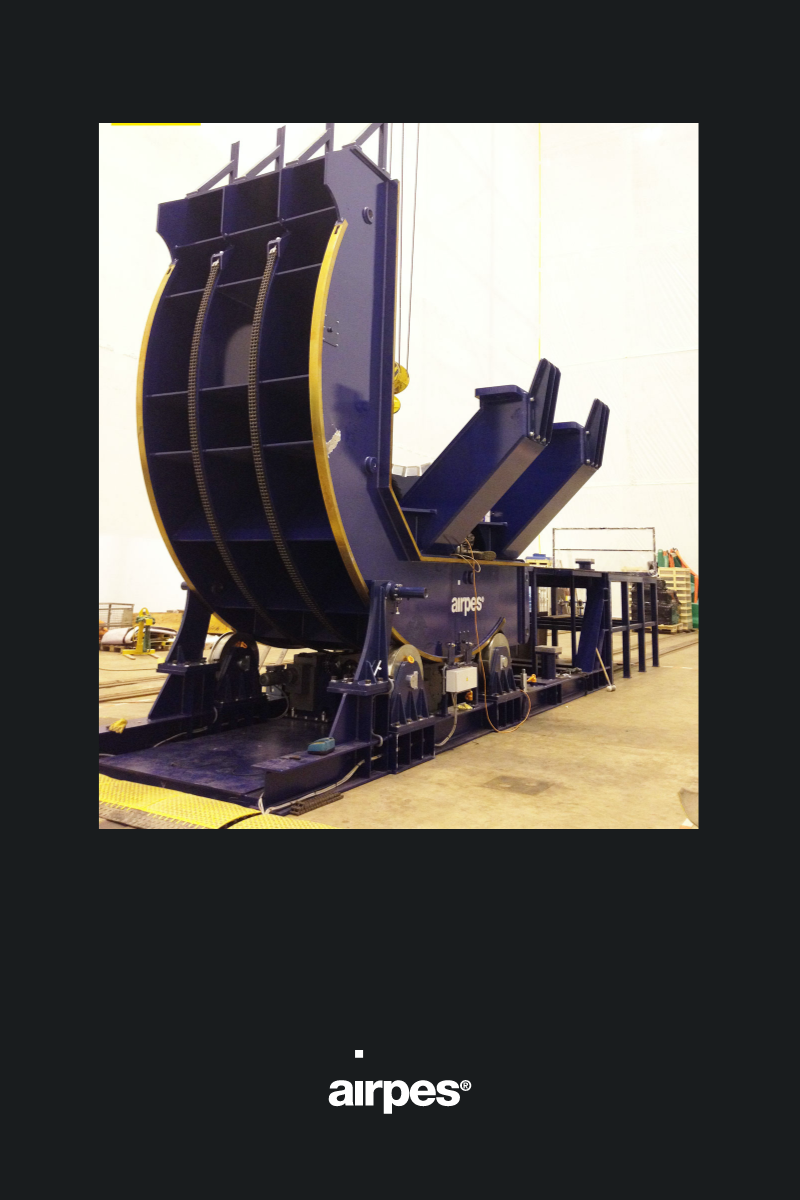

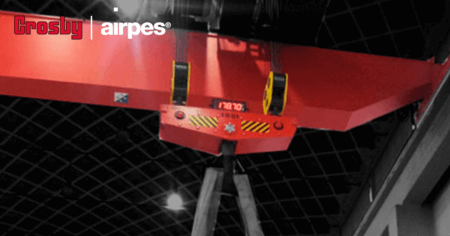

Offshore project: Upender and Gangway for Adwen

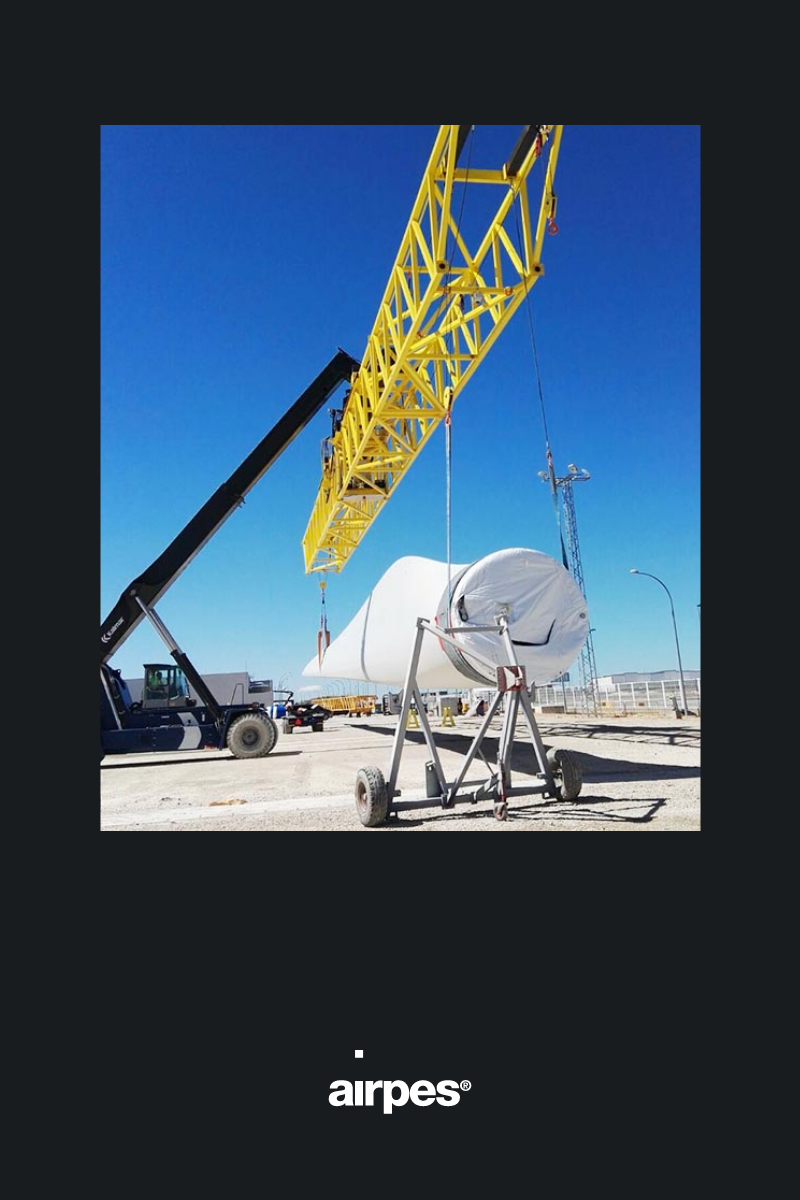

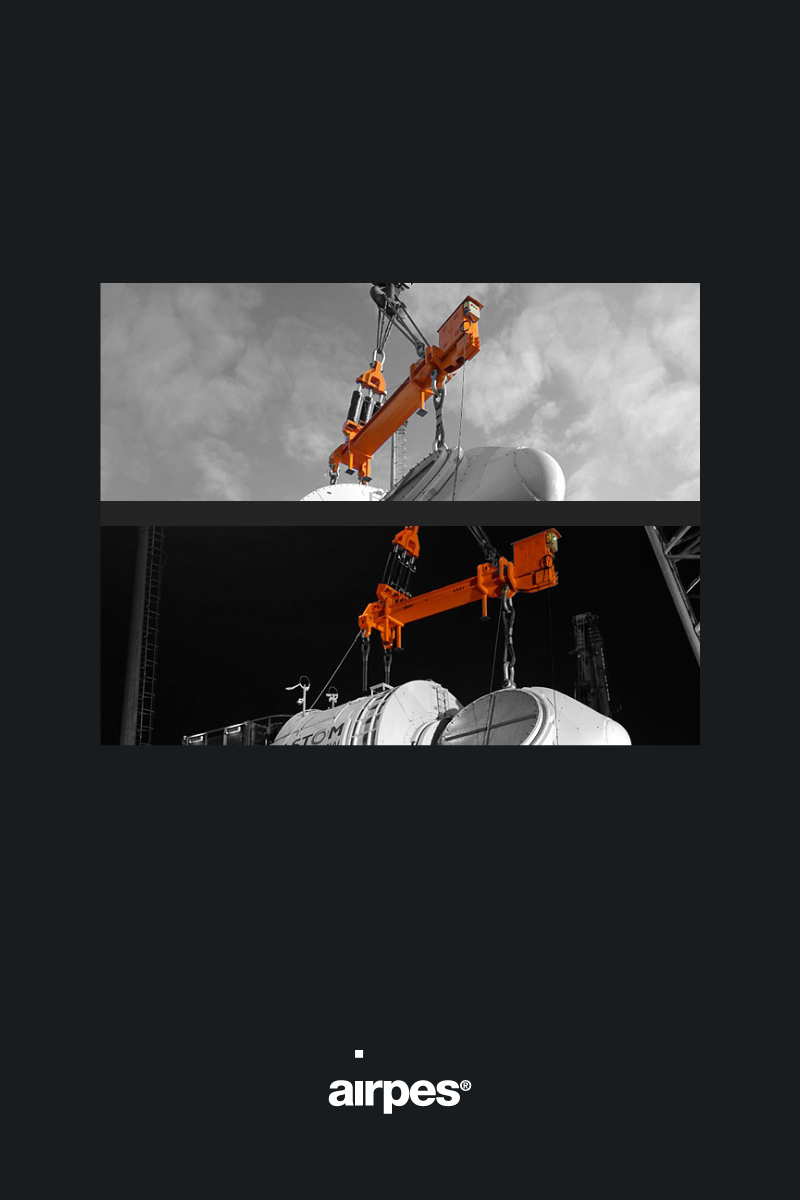

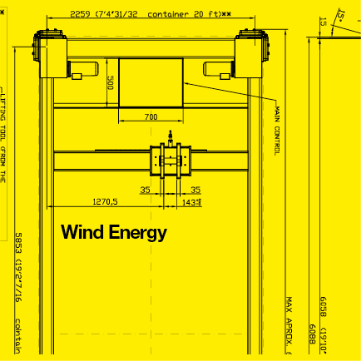

Offshore Company Adwen needed equipment to assemble a part of the JV8-170 or JV8-180 wind turbine, also known as MSA.

Initial situation description

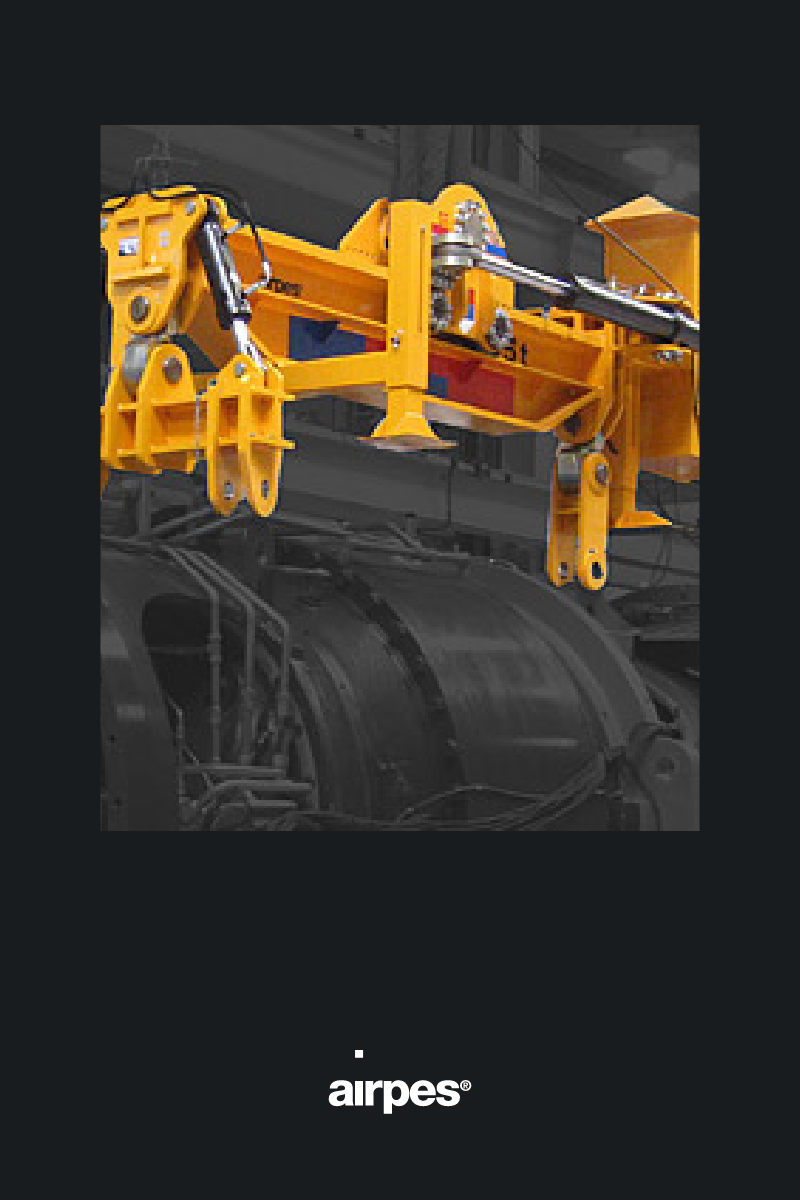

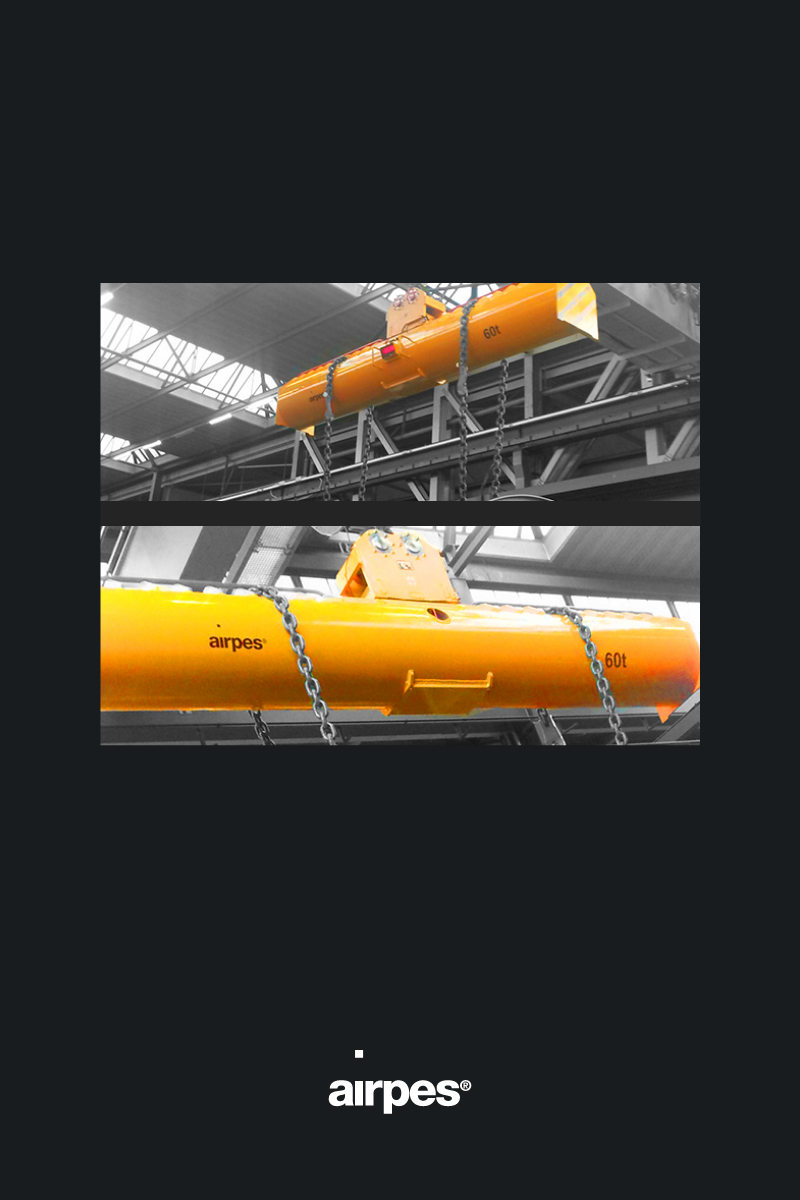

This MSA is composed of two parts: the hollow shaft and the bearing housing structure.

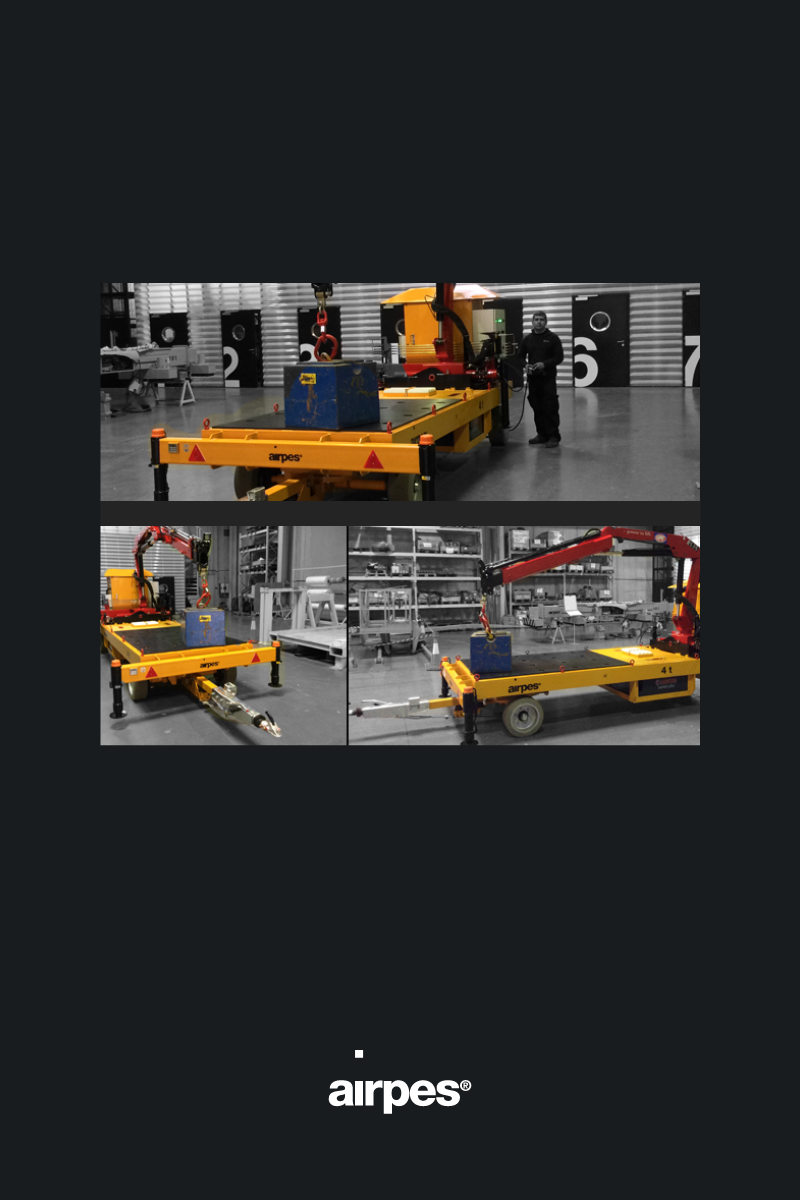

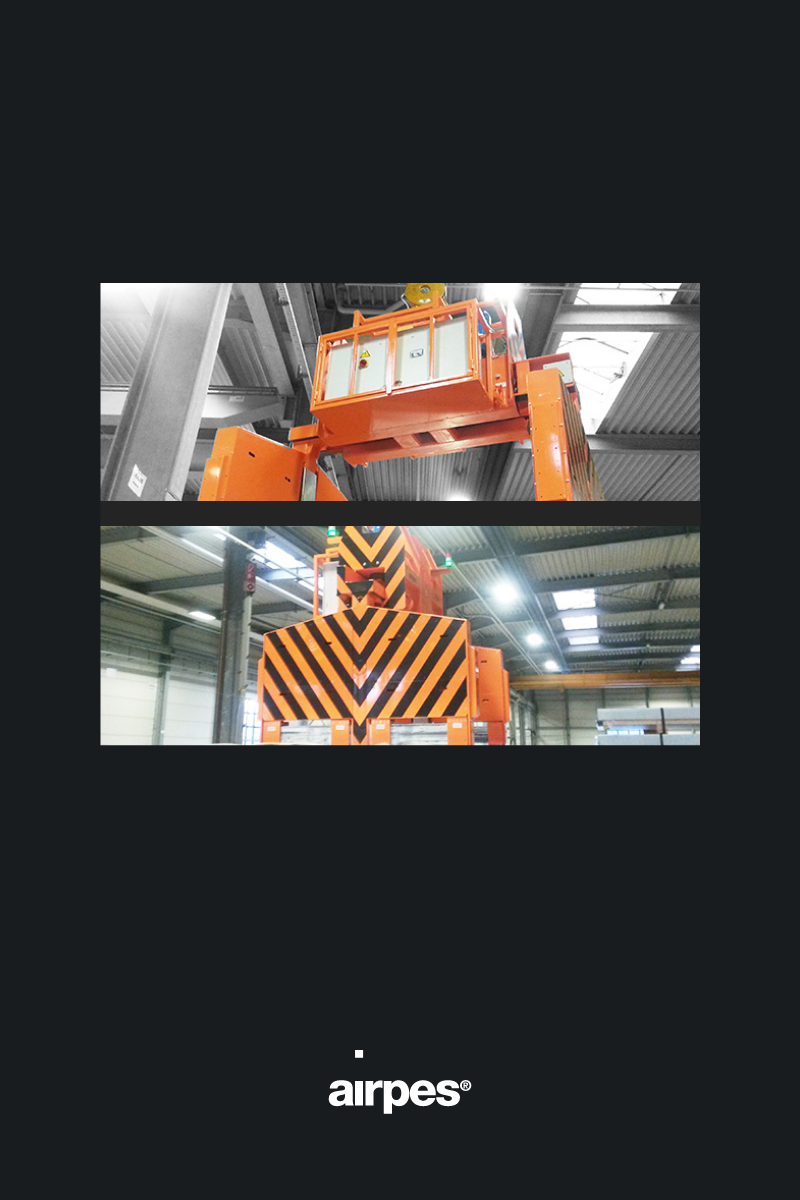

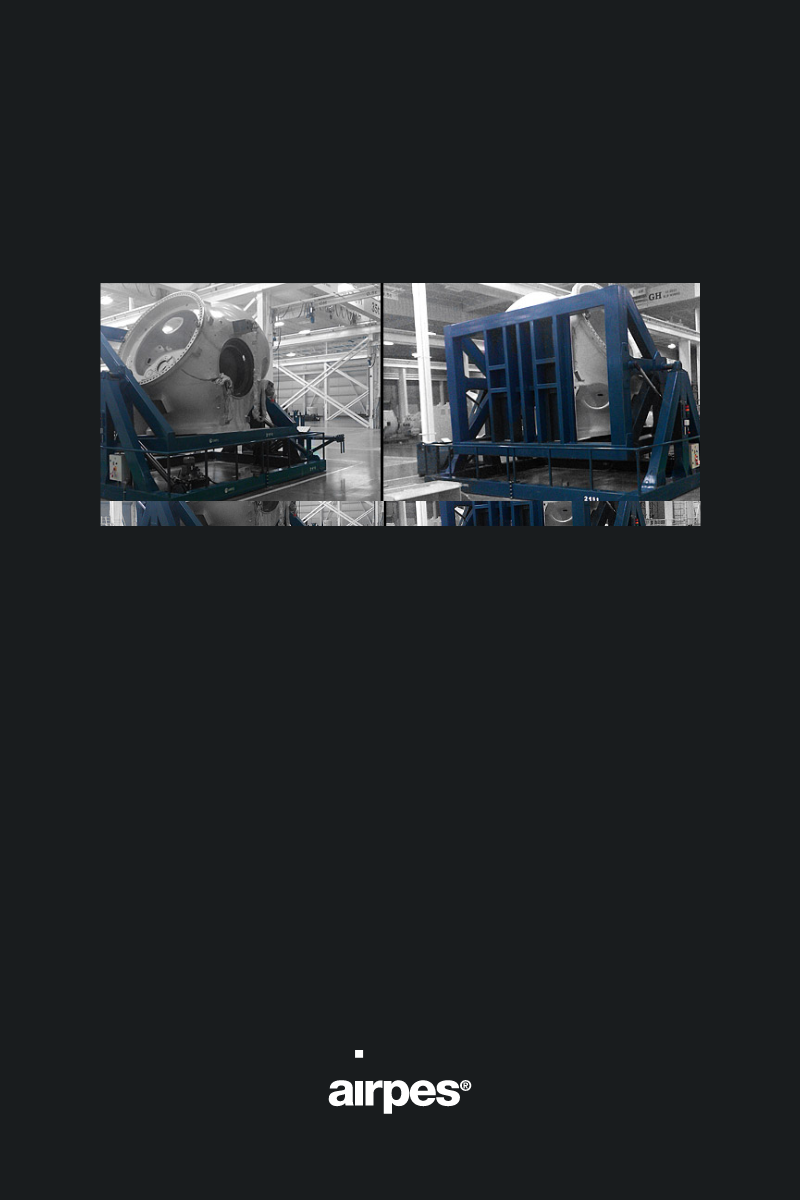

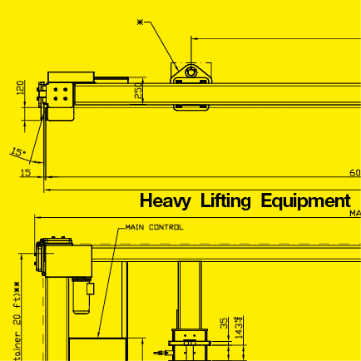

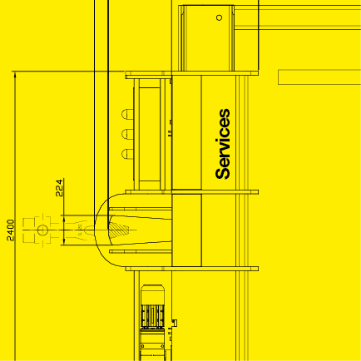

Airpes was in charge of the design of the tilter and the gangway responsible for assembling the MSA parts.

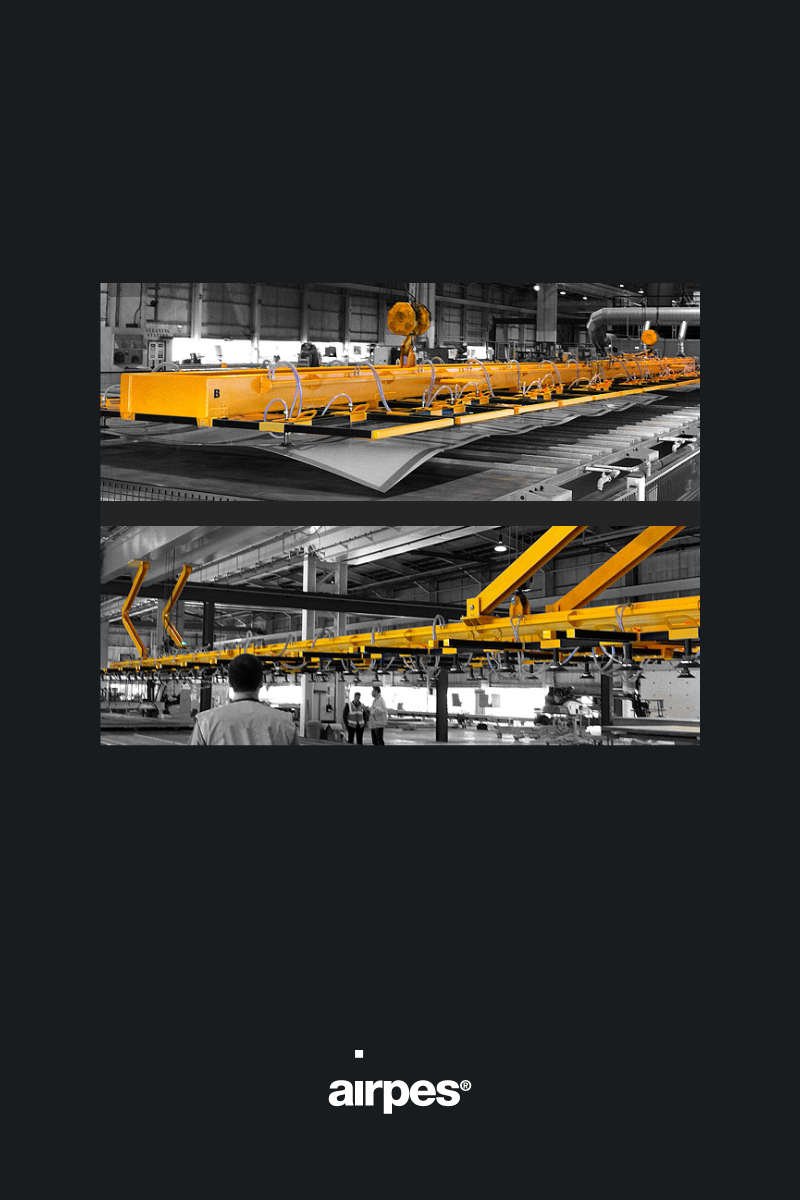

The MSA assembly process comes in two phases:

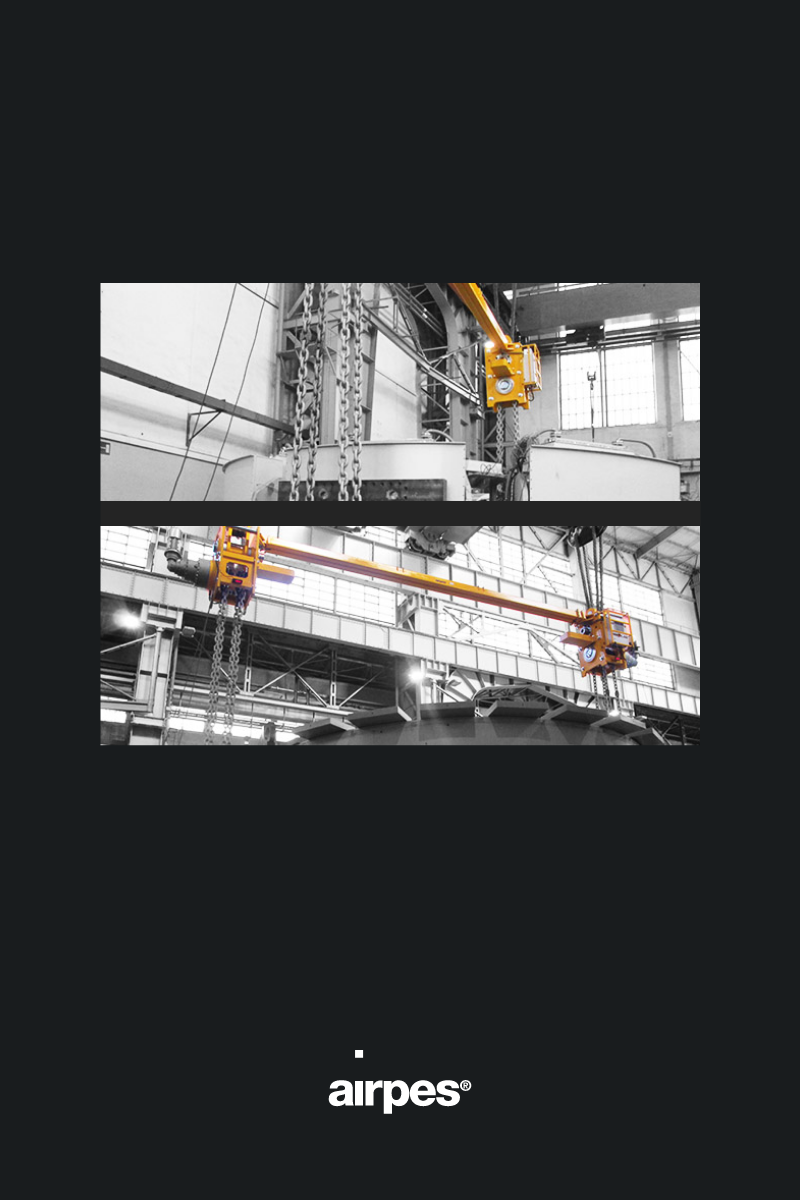

• Turning of the bearing housings

The bearing housings are supported on the upender’s structure horizontally, then vertically and finally the bearings are installed. It is removed from the tilter by a crane and re-installed horizontally and upside-down on the upender, at 180 °.

It is required to repeat the process to install the bearings on that side.

• Hollow shaft

The hollow shaft is installed horizontally and is lifted with the help of the upender at 90º. Finally, the bearing housing is inserted into the hollow shaft and assembled. At the end of these operations, it is necessary to return to the horizontal position to completely assemble the drive train.

OUR on demand solutions

Airpes Solutions

LATEST POSTS ON THE BLOG

Discover our brand new developments, events, get posted of our activity.

- Industrial Load Turning Devices: how to choose the right solutionNot all heavy loads are the same and not all turning devices should be either. In this guide,...

- Industrial scale safety: essential measures for crane scales and lifting equipmentWe review six safety precautions to keep in mind when using a crane scale to minimize some risks...

- Difference between onshore and offshore wind farmsOnshore and offshore wind energy present similarities and differences. We analyze the challenges involved in working in each...

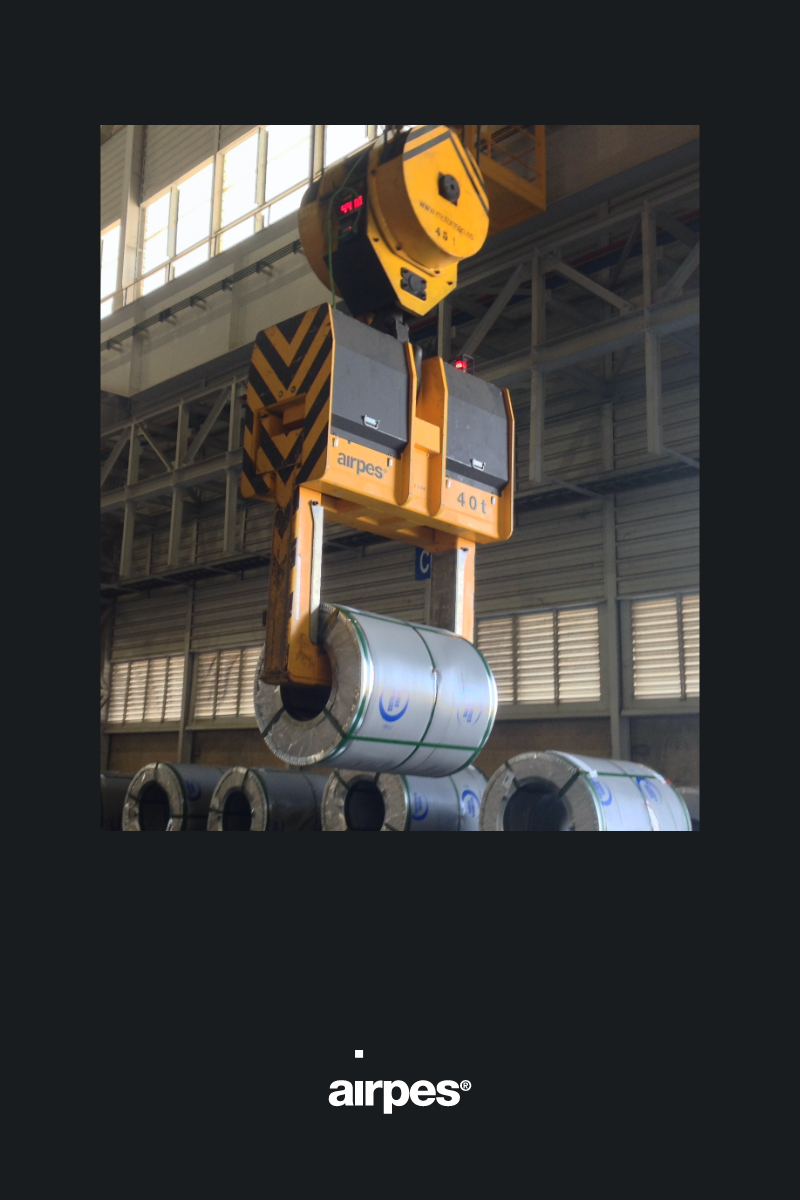

- Types of coil handling devicesDiscover the different types of coil handling devices you can use for handling or lifting any coil: metal...