Have you ever wondered how we approach our lifting tongs design? Each type of lifting equipment must fulfill specific needs that we must consider when manufacturing them.

Get to know the details behind the design of lifting tongs and how they can help to improve your business.

Design is vital for weight lifting equipment performance

The design of lifting tongs and other solutions is crucial, particularly when focusing on personalized solutions, as it directly impacts the efficiency, safety, and user satisfaction in handling diverse materials across various industries.

Personalized design solutions in lifting tongs cater to the specific needs of different operations, materials, and environments, offering tailored functionality that generic equipment cannot provide.

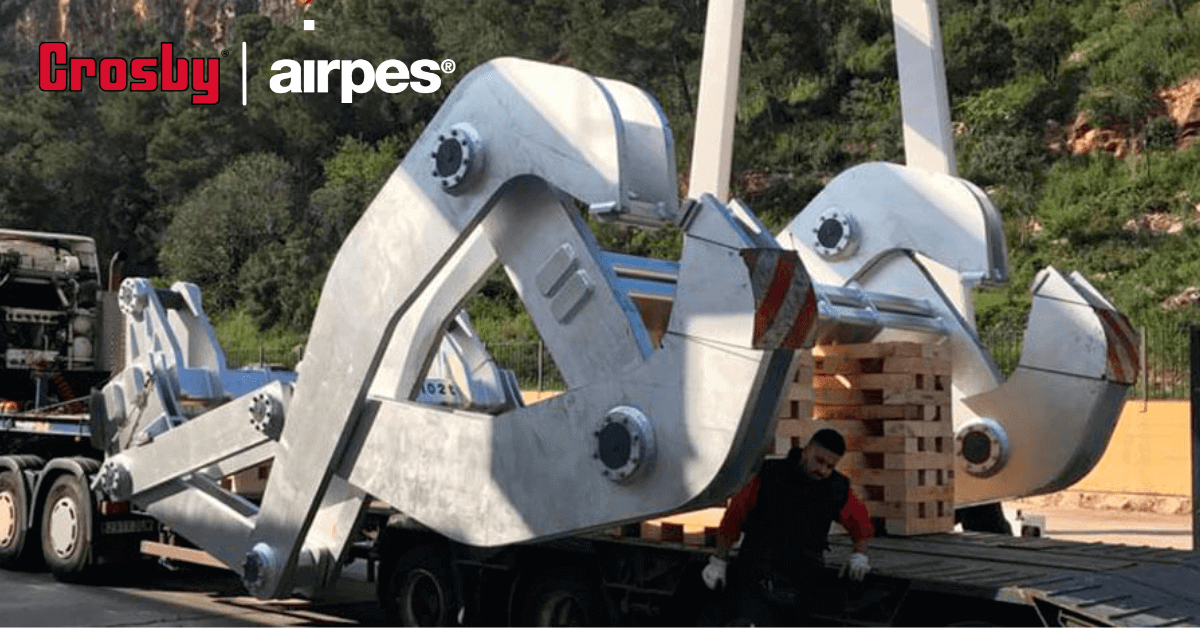

CITA: Crosby Airpes’ lifting tongs designs are engineered to safely grab and lift various materials and objects from existing crane configurations.

You may be interested in: Lifting Magnets Design

General steps of lifting tong design

There are 6 main steps for designing lifting tongs, although a company specializing in this type of tools will adapt the steps for each client.

- Define the requirements. Determine the material, weight, size, and environmental conditions the tongs will be used in.

- Conceptualize the design. Choose the type and gripping mechanism based on the application and material characteristics (this could involve flat surfaces for sheets, curved for cylinders, or custom shapes for irregular objects).

- Detailed Design and Engineering. Create precise CAD drawings, select materials, and perform stress analysis for durability and safety (incorporating locking mechanisms to prevent accidental release of the load).

- Prototype and Testing. Build a prototype for practical evaluation and conduct load tests to ensure safety and functionality (pay attention to the ease of use and the effectiveness of the gripping mechanism).

- Manufacturing and Quality Assurance. Decide on manufacturing processes and implement quality control for consistency and reliability.

- Documentation and Compliance. Prepare user manuals and compliance documents for safe operation and regulatory adherence.

Scalable designs for lifting tongs

Crosby Airpes can scale the lifting capacity of any lifting tongs design. The only limit is the lifting capacity of the crane where the tong will be installed and other factors such as the headroom in the case of the clamp working in indoor spaces.

We can design lifting clamps with the capacity to lift small weights such as several tons to scissor clamps that allow handling up to more than 100 tons of material in a single lift.

Another great advantage of the lifting tongs is that being a relatively simple mechanism, they require less maintenance than other products and can work in environments with dust, humidity, and/or high temperatures without a problem.

Crosby Airpes can design lifting tongs adapted to any crane and desired configuration.

Crosby Airpes help you with your lifting tongs design

At Crosby Airpes, we help you to make great your effort in improve your work. From the beginning to the end, we think, make and improve for you.

Do you have specific needs? We adapt to them with our on-demand solutions.