When we talk about optimizing industrial processes, few investments offer such tangible returns as integrating a digital crane scale into your daily operation. These weighing systems transform a conventional crane into a precise measurement tool, eliminating unnecessary steps and reducing cycle times. At Crosby Airpes, we’ve spent over 20 years designing and manufacturing industrial lifting and weighing solutions, both standard and customized, adapted to each client’s real needs.

If you’re looking for precision, traceability, and reliability in demanding environments, you’re in the right place. Request a quote and discover how we can help optimize your operation.

What is a Digital Crane Scale (Digital Crane Weighing Scale)?

A digital crane scale is a precision electronic device that suspends from a crane hook to measure load weights during lifting operations. Unlike traditional analog scales—which relied on mechanical mechanisms with needles and springs—or hydraulic dynamometers, a digital system uses electronic load cells that convert applied force into electrical signals processed by microcontrollers.

The main advantage lies in accuracy and repeatability. While a mechanical dynamometer may present deviations due to wear, material fatigue, or environmental conditions, a modern digital crane weighing scale offers resolutions up to 0.01% of nominal capacity, with automatic temperature compensation and self-diagnostic capabilities. This not only improves precision but also provides digital data that can be integrated directly into management systems, traceability protocols, or quality control processes.

Key components of a digital crane scale

- Load cell body designed for the working load limit (WLL) and a defined safety factor.

- Hook or shackle interface sized for the rigging chain, sling, or hook block.

- Electronics with stable A/D conversion, temperature compensation, and filtering to cope with vibration.

- Display and telemetry options: handheld indicator, overhead display, or data sent to PLC/SCADA.

- Power system (battery/charger) sized for your duty cycle.

How a digital crane scale works

Inside the digital crane scale, strain gauges bonded to the load-bearing body form a Wheatstone bridge. As the load changes, the bridge output varies proportionally. The electronics amplify and digitize the signal, apply calibration factors, and present a stable weight reading. In advanced models, the digital crane scale streams data wirelessly to a remote display, historian, or MES. Autonomy depends on battery capacity, duty cycle, and environment; quality designs maintain repeatability and resolution across the operating range, even in harsh conditions.

Safety by design

A properly engineered digital crane scale is built around the rigging path, not around the electronics. Bodies are designed with safety factors above rated capacity, and housings protect the measurement chain from impact, dust, and moisture (IP rating per application). Overload events can be limited or monitored with complementary devices when your risk assessment requires it.

Where to Use a Digital Crane Scale: Industries & Use Cases

Steel and Metal Production, Ports and Logistics, Wind Energy, Heavy Manufacturing, and MRO

The versatility of digital crane weighing scales makes them indispensable across a range of industrial sectors.

In steel mills and metal production facilities, precision weighing directly impacts both quality control and profitability —a 0.5% error on a 20-ton load means significant revenue loss, making real-time verification from furnace to shipping essential.

Ports and logistics operations rely on integrated crane scales for SOLAS-compliant verified gross mass (VGM) measurements, eliminating truck scale queues and dramatically improving terminal throughput.

The wind energy sector uses these systems for safe handling of massive turbine components (100+ ton nacelles, 60+ meter blades), where real-time load monitoring is critical for offshore installations with tight weather windows.

Heavy manufacturing environments (aerospace, shipbuilding, pressure vessel fabrication) deploy digital scales for continuous process control during assembly, catching weight distribution errors before they become costly rework.

Maintenance, repair, and operations (MRO) teams use weighing as diagnostic verification, confirming complete reassembly of motors, pumps, and gearboxes before returning equipment to service.

Selection guide: choosing the right digital crane weighing scale

Choosing the appropriate digital crane scale for your operation isn’t about finding the “best” model—it’s about matching capabilities to your specific requirements. Let’s break down the critical decision factors.

Capacity & safety factor (WLL)

Select a digital crane scale with a capacity that covers your typical range and peaks, with a clear margin. Factor in rigging weight and dynamic effects. Look for well-documented safety factors and materials suitable for the temperatures and shocks of your process.

Accuracy & resolution

Accuracy classes, repeatability, and minimum divisions determine how actionable your readings will be. A well-calibrated digital crane scale provides consistent results across the full range; resolution should match the tolerance you use for billing, batching, or acceptance testing.

Environment & duty cycle

Temperature swings, dust, humidity, and vibration influence measurement stability. Specify the digital crane scale IP rating, mechanical protection, and battery autonomy for the number of lifts per shift. For outdoor or marine environments, consider corrosion protection.

Display, connectivity & integration

Decide how operators will read and log the weight. Many workflows benefit when the digital crane scale connects to handheld indicators, large overhead displays, or directly to PLC/SCADA and data historians. If you manage recipes or production batches, ask for data logging and export formats aligned with your software.

Ergonomics & maintenance

Battery change/charge simplicity, charger placement, and accessory compatibility matter to uptime. A digital crane scale that is easy to service—connectors, access to calibration ports, and spare availability—reduces lifecycle cost.

Tip: if you compare multiple models, create a short checklist: capacity, accuracy, IP rating, autonomy, indicator type, and integration options. Weight the criteria by your process risk and lead time constraints.

Compliance & quality: how we build and validate

We follow stringent quality procedures in design, manufacturing, and calibration of every digital crane scale. Metrological traceability, documented calibration steps, and functional tests are part of our standard workflow. All of our design and manufacturing processes are ISO 9001:2000 certified by the renowned German institute TÜV.

Bringing your internal QA requirements to the discussion helps us align tolerances, certificates, and test procedures with your standards.

You may be interested on: “Benefits of using a crane scale”

Related Lifting & Weighing Solutions

A digital crane scale is often just one component of a comprehensive industrial weighing and material handling strategy. Understanding the full range of available solutions helps you optimize your entire workflow rather than just solving a single measurement challenge.

Weighing Hooks

Weighing hooks represent the most straightforward implementation of crane-based weighing. These systems suspend directly from your crane’s existing hook or cable, requiring no modification to the crane itself. This makes them ideal for facilities with multiple cranes where weighing requirements shift between locations, or for rental fleets where equipment moves between job sites.

-

ELECTRONIC CRANE SCALE AGE-120

The AGE-120 electronic crane scale has been designed to be hung up from the hook of the overhead traveling crane,…ELECTRONIC CRANE SCALE AGE-120September 22, 2020 -

ELECTRONIC CRANE SCALE AGM-180

The electronic crane scale AGM-180 has been designed to be hung up from the hook of the overhead traveling crane,…ELECTRONIC CRANE SCALE AGM-180September 22, 2020 -

ELECTRONIC CRANE SCALE AGP-100

The AGP-100 electronic crane scale is an appropriate device for the control of entering and leaving of a product, control…ELECTRONIC CRANE SCALE AGP-100September 22, 2020

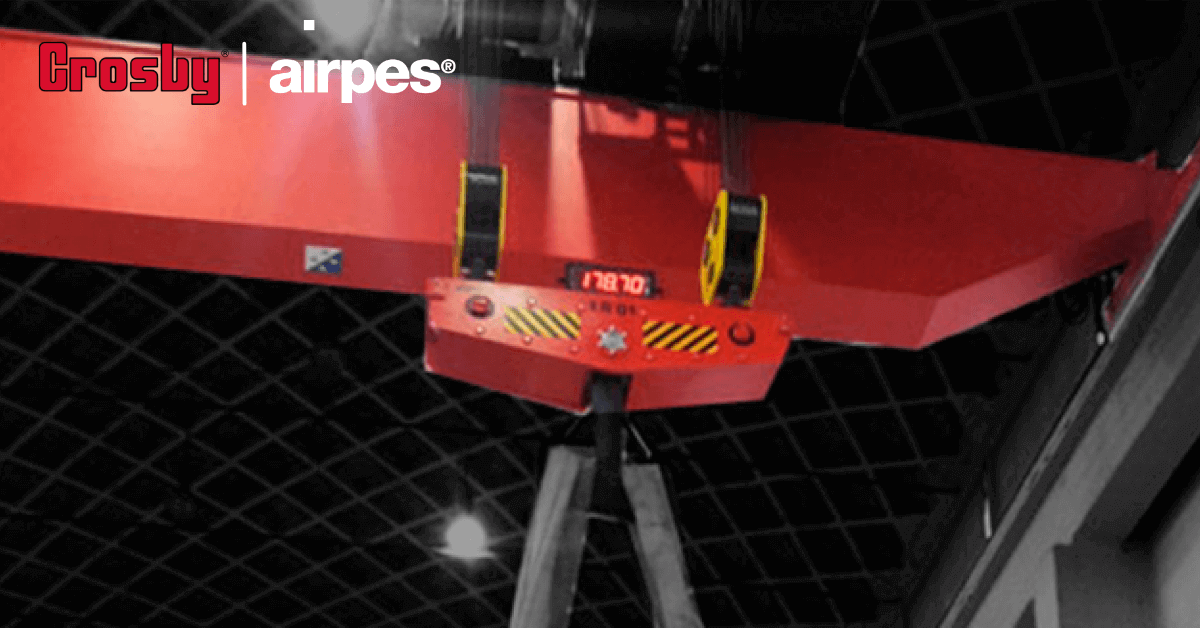

Weighing hook blocks

Weighing hook blocks are the perfect element for automatically carrying out two tasks at the same time.

A lifting and weighing hook block will allow us to lift any type of load with a hook at the same time as we are weighing it.

With a weighing block two tasks are carried out at the same time: a load is lifted and transported at the same time as it is weighed. In addition, as the block itself performs the weighing, we save the need to install an additional scale and we do not lose height from the ceiling (headroom) with our crane. Our ATP-100 weighing block can be installed on any type of crane. A backlit LED or LCD panel indicates the weight in a precise way, besides being able to control almost all the functions remotely with a remote control system.

Our lifting block ATP-100 can be scaled to perform weighing ranging from 2,000 to 250,000 kg.

-

HOOK BLOCK SCALE ATP-100

The ATP hook block scale is an electronic weighing system of great precision, thought to be adapted to any type…HOOK BLOCK SCALE ATP-100November 15, 2020

Weighing pallet truck

As in the case of weighing block, a weighing pallet truck allows two tasks to be performed automatically at the same time: transporting a material from one place to another at the same time as the material is weighed. With a weighing pallet truck you gain time and efficiency in any logistics warehouse, in addition to reducing the risks in the workplace as it is not necessary to transport the loads to an industrial scale to proceed with weighing.

Accessories & monitoring

- Electronic limiters to supervise overload risks alongside the digital crane scale.

- Mechanical limiters for simple, rugged protection.

- Load cells for custom fixtures or embedded weighing points tied into a digital crane scale.

On-demand engineering

See how we adapt weighing systems to unique constraints in this real case: On-demand weighing system for a Swiss company.

Why Crosby Airpes

As part of the Crosby Group, Crosby Airpes designs and manufactures lifting, handling, and weighing solutions for heavy industry. Our engineering team works end-to-end—from application study and risk analysis to design, manufacturing, FAT, and commissioning. That means your digital crane scale is not a standalone device; it is a reliable element inside your process.

Practical tips to get more value from your digital crane scale

- Define the job. List your heaviest loads, rigging weights, and environmental constraints.

- Plan data flow. If you need traceability, involve your automation team early so the digital crane scale outputs (wired or wireless) map to your data systems.

- Protect the rigging path. Make sure the scale body, shackles, and hooks keep the correct geometry to avoid side-loading and preserve accuracy.

- Schedule calibration. Set a simple calibration routine and keep a record. A stable digital crane scale fosters trust across shifts and audits.

- Train operators. A two-minute refresh on zeroing, tare, and reading practices reduces errors and speeds up operations.

Conclusion

A digital crane scale improves safety, compresses handling time, and gives you the data you need to run tighter operations. Whether you are validating inbound material, batching in production, or loading for shipping, the right digital crane scale delivers reliable numbers at the hook—and integrates with the systems you already use.

Need help specifying the optimal solution? Our engineering team can assess your lifting points, environment, and data requirements and recommend the digital crane scale configuration that fits your process. Let our specialists help you select the most suitable industrial weighing solution for your needs.