Selecting the wrong crane lifting equipment has derailed more industrial operations than most facility managers care to admit. The performance gap between facilities using engineered crane lifting equipment versus generic attachments is staggering. Whether you’re managing steel processing operations, shipyard assembly lines, or aerospace manufacturing, the lifting systems connecting your crane to the load determine your operational efficiency, safety margins, and ultimately, your bottom line.

Understanding Custom Crane Lifting Equipment

Crane lifting equipment encompasses all the specialized attachments and below-the-hook devices that bridge your crane’s hook to the load. These are engineered systems that determine how safely, efficiently, and precisely you can handle materials in your facility.

Modern heavy lifting equipment crane systems go far beyond basic hooks and cables. They incorporate load monitoring, remote control capabilities, and modular designs that allow a single crane to handle dozens of different materials simply by switching out the lifting attachment. This versatility separates facilities that maximize their crane investments from those constantly struggling with limitations.

Types of Crane Lifting Equipment: Finding the Right Solution

Let’s explore the key options and when each makes the most sense for your operations.

Below-the-Hook Lifting Devices

Below-the-hook devices form the critical connection between your crane and the materials you’re moving. Each type excels in particular applications.

Lifting Beams and Spreader Bars

Lifting beams distribute crane loads across multiple lifting points, preventing damage to materials that couldn’t withstand concentrated forces at a single point. Standard lifting beams work beautifully for balanced loads, but what about materials with off-center weight distribution? That’s where hydraulically adjustable beams come in, with mobile centers of gravity that automatically compensate for unbalanced loads.

Spreader bars extend even further, providing four-point or six-point lifting configurations. The capacity range is remarkable: from compact 5-ton beams for machine shop work up to massive 500-ton systems for bridge construction and offshore installations.

-

LIFTING BEAM

Engineered lifting beams for industrial environments At Crosby Airpes, we design lifting beams that meet the highest standards of safety,…LIFTING BEAMSeptember 22, 2020 -

SPREADER BEAM

Airpes spreader beams are the perfect solution if you need a lifting beam and you don't have a low headroom…SPREADER BEAMSeptember 22, 2020

C-Hooks and J-Hooks

C-hooks revolutionized how industries handle coiled materials. Steel service centers, cable manufacturers, and paper mills rely on these specialized crane lifting equipment pieces daily. The design is elegant: a curved hook that cradles coiled materials through their center bore, distributing weight evenly.

What separates adequate C-hooks from exceptional ones is the ability to adjust to different coil diameters. The best designs feature variable opening widths, allowing facilities to handle everything from tight cable coils to wide steel coils with the same device. Some models incorporate motorized rotation, enabling operators to orient coils precisely before placement.

J-hooks serve a similar purpose but with an open design that allows side loading, invaluable in confined spaces where you can’t position the crane directly above the coil’s center.

Lifting Tongs and Grabs

When materials lack convenient lifting points, lifting tongs provide the solution. These self-gripping devices use the weight of the load itself to maintain a secure hold: the heavier the load, the tighter the grip.

Scissor lifting tongs excel at handling steel plates, concrete beams, and tree logs. The key is matching the tong design to your material. Handling steel slabs requires hardened gripping surfaces and precise jaw geometry to prevent slippage. Systems range from compact 500kg units for workshop applications up to heavy-duty 100-ton systems for steel mill operations.

-

COIL LIFTING TONGS

Check out our vertical coil tongs, designed by our engineers to meet every customers' requests on mechanical features, electronic components,…COIL LIFTING TONGSSeptember 22, 2020 -

SCISSOR LIFTING TONGS

Scissor lifting tongs are designed and manufactured by Airpes to lift and handle different types of loads. Our product features…SCISSOR LIFTING TONGSSeptember 22, 2020

Specialized Heavy Lifting Equipment Crane Systems

Load Rotators

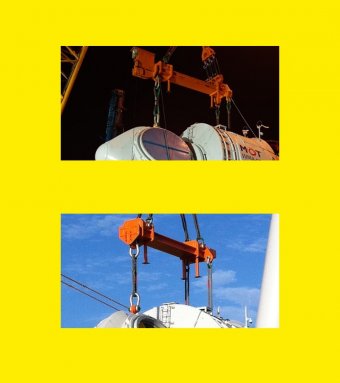

Manufacturing aircraft fuselages, assembling ship engines, or building wind turbine components all share a common challenge: these massive objects need rotation during assembly while suspended. Load rotators make this possible.

These sophisticated systems incorporate electric or hydraulic motors that rotate loads through 360 degrees while hanging from the crane. The control is precise: you can position a 20-ton aircraft section within millimeters of your target alignment. Advanced designs include integrated load weighing systems that provide real-time center-of-gravity data, ensuring balanced rotation even with complex assemblies.

-

LOAD ROTATOR

Meet our range of high capacity electric powered rotators designed to rotate all types of materials. It can be adapted to…LOAD ROTATORSeptember 22, 2020

Electro-Permanent Lifting Magnets

For facilities handling ferromagnetic materials (steel plates, structural components, processed metal) lifting magnets eliminate the need for slings, chains, or manual rigging.

Electro-permanent magnets represent the latest technology. Unlike electromagnetic systems requiring constant power, these use a brief electrical pulse to magnetize or demagnetize, then hold loads purely through permanent magnetism. This creates an inherently safe system: power loss doesn’t result in dropped loads.

The versatility extends to handling multiple plates simultaneously. A single magnet system can lift one thick plate or multiple thin plates in a stack, adjusting automatically.

-

LIFTING ELECTRO MAGNET

We have the most interesting products in the industrial electromagnet field because we are in charge of the whole lifting electromagnet design, but…LIFTING ELECTRO MAGNETSeptember 22, 2020

Motorized Rotating Crane Blocks

Sometimes you need rotation capability without the complexity of a full load rotator. Motorized rotating crane blocks provide this solution: compact devices that install directly between the crane hook and your lifting attachment, offering 360-degree rotation in a maintenance-friendly package.

What makes these valuable as crane lifting equipment is their modularity. You’re not dedicating a specialized rotator to a single application. Instead, the rotating block travels with the crane, available whenever rotation capability is needed.

-

MOTORIZED ROTATING CRANE BLOCK

One of the most demanded applications is the motorization of the crane’s hook block (often called crane blocks or crane…MOTORIZED ROTATING CRANE BLOCKSeptember 22, 2020

How to select the right Crane Lifting Equipment for your operation

Walking into a lifting equipment catalog without a clear selection criteria is overwhelming. Let’s establish a practical selection process.

Load Capacity and Weight Distribution

Start with actual load weight plus the weight of the crane lifting equipment itself. Facilities commonly calculate load weight correctly but forget that the lifting beam, C-hook, or tongs adds hundreds or even thousands of pounds to what the crane must lift. A 10-ton rated crane using a 500-pound lifting beam has only 9,750 pounds of usable capacity remaining.

Weight distribution deserves equal attention. A 5-ton load concentrated at a single point creates different stresses than the same weight distributed across four lifting points. Materials like glass panels or thin-walled tanks often lack the local strength to withstand concentrated loads: this is where lifting beams prove essential for protecting delicate loads from the lifting process itself.

Center of gravity calculations can’t be ignored. An off-center load using standard equipment will swing when lifted, creating dangerous pendulum effects. This is where adjustable lifting beams or load rotators with self-leveling features become necessary.

Material Characteristics and Handling Requirements

Every material presents unique handling challenges. Steel coils demand C-hooks or coil tongs. Steel plates work with lifting magnets or plate tongs. Awkward machinery might require custom spreader beams with multiple attachment points.

But it goes deeper than basic compatibility. Consider surface finish requirements… are you handling polished stainless steel that can’t tolerate grip marks? Standard tongs might leave impressions, requiring designs with rubberized jaws or nylon-protected contact surfaces.

Temperature matters too. Handling materials fresh from heat treatment requires crane lifting equipment rated for those conditions. Standard grease-lubricated mechanisms fail in high-heat environments…you need systems designed specifically for those conditions.

For a deeper dive into this topic, our guide on how to select material handling equipment explores critical selection factors in detail.

Environmental and Safety Considerations

Your operating environment shapes equipment selection as much as the loads themselves. Outdoor applications face weather exposure (rain, humidity, temperature extremes) therefore standard crane lifting equipment won’t survive these conditions.

Explosive atmospheres in chemical plants or grain facilities demand ATEX-certified equipment. Spark-producing mechanisms aren’t just discouraged, they’re prohibited. Every component must meet explosion-proof standards.

Operator visibility is crucial. In high-bay warehouses or cluttered manufacturing spaces, visibility is often limited. This is where remote control systems integrated with your heavy lifting equipment crane setup become crucial for safety. Wireless control solutions give operators freedom to position themselves for optimal visibility while maintaining complete control over lifting operations.

Load monitoring adds another safety layer. Electronic systems that display real-time load weight prevent overload situations before they become dangerous. For facilities handling varied loads throughout the day, this feedback proves invaluable.

Maximizing Crane Performance with Advanced Lifting Attachments

Your crane represents a significant capital investment, but its return is directly proportional to how well you’ve equipped it with appropriate crane lifting equipment.

Remote Control Systems Integration

Manual crane operation from a suspended cab or floor pendant creates inherent limitations. Remote control systems eliminate these constraints. We integrate wireless control technology into heavy lifting equipment crane installations. Operators can position themselves to maintain visual contact throughout the lift, with emergency stop functions literally in their hand. Response time to unexpected situations drops from seconds to milliseconds.

Interchangeable Lifting Systems

Rather than dedicating cranes to specific tasks, design your lifting equipment inventory to be interchangeable. A single overhead crane can handle steel plates in the morning using lifting magnets, switch to C-hooks for coil handling in the afternoon, and finish the day moving machinery with a custom spreader beam.

This flexibility requires planning. Your crane’s hook height must accommodate the tallest lifting attachment without losing useful lift. The quick-change mechanism between the crane hook and different attachments needs to be safe and efficient.

You may also be interested in this complementary resource: our in-depth analysis of crane lifting hooks explores how different hook designs and attachment systems impact the versatility and safety of your lifting operations.

Conclusion: Transform Your Lifting Operations with the Right Equipment

The crane lifting equipment hanging from your overhead cranes defines what your operation can accomplish. Outdated lifting beams limit your versatility. Generic C-hooks force compromises in how you handle coils. Absent load monitoring systems, you’re operating without critical safety data.

Upgrading or expanding your heavy lifting equipment crane systems doesn’t require replacing cranes or reconfiguring your facility. Often, the highest-return investment is precisely engineered lifting attachments that unlock capabilities your existing cranes already possess.

For comprehensive guidance on our range of industrial lifting solutions, visit our dedicated heavy lifting equipment landing page.

Contact our team today for a detailed consultation. We’ll discuss your specific applications, evaluate your current equipment, and provide expert recommendations backed by four decades of engineering excellence.