Material handling equipment is essential in any industrial environment where it is necessary to move, lift, hold, store, or transport loads safely and efficiently. These systems, internationally known as Material Handling Equipment (MHE), allow for the optimization of processes, reduction of operating times, and improvement of safety in sectors such as steel, automotive, construction, wind energy, heavy logistics, and many others.

When choosing the most suitable handling material for a given industrial task, doubts may arise. In this post, we will discuss the different types of material handling equipment to resolve them.

What is industrial material handling equipment?

Industrial material handling equipment covers a wide range of tools, storage units, apparatus and accessories used to transport, store, control, list and protect products at any stage of manufacture, distribution, consumption or disposal.

These systems are specifically used to:

- Lift loads.

- Hold and transport materials.

- Rotate, turn over, or position parts.

- Handle coils, sheets, plates, structures, or industrial components.

- Improve operational safety and efficiency.

This is a very broad category that includes everything from lifting equipment to gripping devices, industrial magnets, or load rotators. All of them share the common goal of automating, facilitating, and securing the handling of any type of load.

Lifting Equipment vs. Material Handling Equipment

Although often used interchangeably, there is an essential nuance. Lifting equipment (cranes, hoists) focuses on the vertical and horizontal movement of a load in a limited area. Material handling equipment or MHE material handling equipment, on the other hand, is the accessory or implement connected to the lifting equipment (or a vehicle) that directly interacts with the load.

At Crosby Airpes, we manufacture solutions that combine both functions, allowing for complete load handling with a single customized system.

Sectors where material handling systems are used

The need to move heavy, bulky, or delicate loads makes material handling equipment indispensable in virtually any industrial sector. Crosby Airpes has extensive experience in:

- Steel and Metallurgy: Handling of coils, slabs, billets, and large steel parts.

- Construction and Civil Engineering: Moving tunnel sections, precast concrete, and wire mesh.

- Wind and Energy: Handling of wind turbine components and power plant parts.

- Logistics and Storage: Solutions for containers and large components.

Types of material handling equipment

Below is a complete classification detailing the material handling equipment most commonly used by the industry:

Lifting Equipment

Systems designed to distribute the load and securely attach to the crane hook.

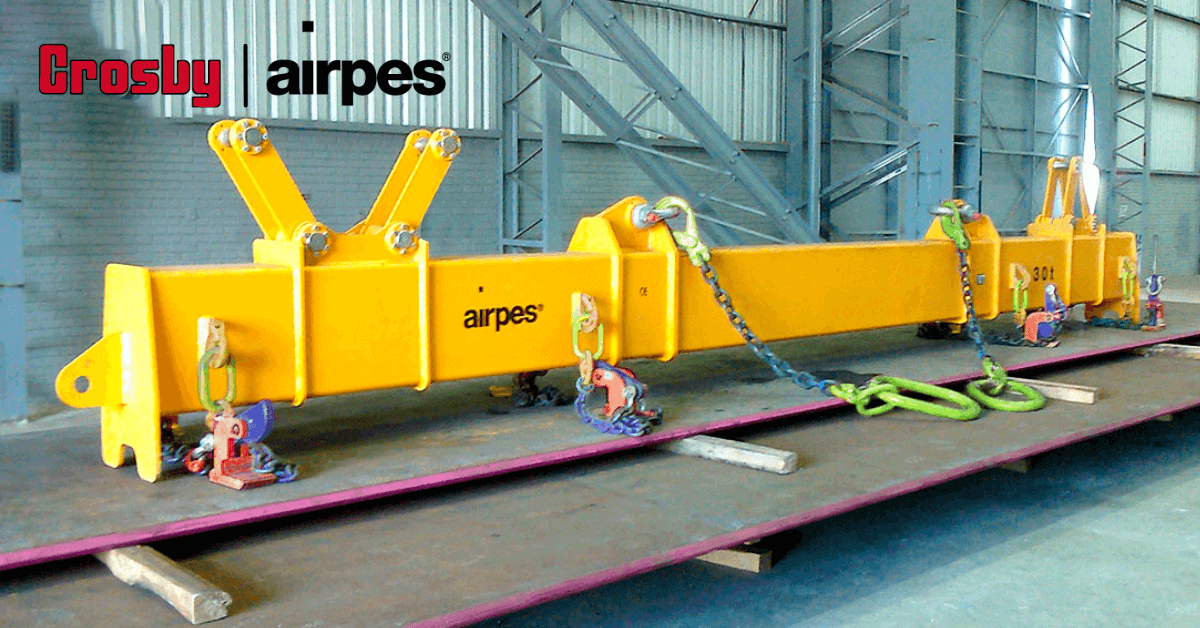

Lifting Beam

C Hooks

A lifting beam is a solid piece of metal beam designed to be attached to a crane hoist by a rigging consisting of a chain or lifting wire. It allows to lift objects whose weight is not equilibrated or cannot be lifted with a standard lifter.

We offer many types of lifting beam designs, some of them are: fixed beams, H beams, moveable centre of gravity beams, hydraulic powered beams or spreader beams.

C-Hooks are essential for the horizontal handling of coils and rolls of paper or metal. They are designed to lift and move wire or rope coils in a safe efficient and quick way. Our c-hooks are designed to meet every customer’s specific requirements for load configuration, weight, lifting area and headroom available.

With the C Type crane hook you will be able to move any coiled wire with your existing overhead crane, no matter which type of crane it is.

Sheet Lifter

The sheet lifter provides fast and smooth leg adjustment and allows for additional force to be applied to the sides of the loads. It helps you loading sheets no matter its size. The plate lifter is a heavy duty handling system designed to efficiently lift the load and safely handle it.

Gripping and Clamping Equipment

Systems that ensure secure and damage-free mechanical fixation to the workpiece

Scissors Tong

Suitable for all types of materials (steel, concrete, structures…). Scissor tongs are custom-manufactured according to the load, process, and existing facility.

Coil Lifting Tong

Coil Tongs are the most efficient and safe way to handle large coils. These tongs can be custom designed according to the needs of the client, type of use, material of the roll, type of lifting beams or hoist, lifting requirements, etc.

Tunnel Segment Tong

Designed to handle concrete segments. They incorporate sensors that guarantee completely safe lifting. These tunnel concrete segment tongs are manufactured in all sizes and capacities according the customer’s request. They have sensors on the legs and in the laterals to detect the segments and when all sensors are activated, the machine operator can lift the load in a secure way.

Mesh Nippers

Mesh Nippers are designed to handle packages of large and heavy electro-welded mesh. They allow for the handling of wire mesh with a single operator and complete safety, reducing loading and unloading times.

Magnetic Equipment

Used for the quick and efficient handling of ferrous loads, without the need for mechanical anchors.

Electromagnets

Electromagnets are a versatile solution for moving ferromagnetic materials. They are ideal for demanding environments and high-intensity processes. They operate in extreme conditions and allow for quick and safe operation.

Rotation and Positioning Equipment

Systems that allow for controlled rotation and precise orientation of the load.

Load Rotators

The load rotator consist in an electric powered rotator designed to turn all types of materials 360 degrees with millimeter control, essential for manufacturing and assembly processes. It can be adapted to all type of hoists and cranes.

We can produce a different types of load rotators, adequate to the customer’s demand. The design can be adapted for the rotation of different elements and parts.

Load rotators

The load rotator consist in an electric powered rotator designed to turn all kinds of materials. It can be adapted to all type of hoists and cranes. Crosby Airpes can produce a different types of load rotators, adequate to the customer’s demand. A load rotator can be adapted for the rotation of different elements and parts. We As well the design can be adapted to multiple uses and weights. The material being turned will move 360 degree and can be stopped in any position. The harnesses used with the device will turn the loads in a slow and efficient way.

How to Choose Material Handling Equipment: Practical Guide

Choosing the appropriate material handling system is an engineering decision that directly impacts the profitability and safety of your plant. As experts in MHE material handling equipment, we advise you to focus on these critical factors:

1. Material Type and Dimensions

The nature of the load is the starting point. Is it a coil, a plate, or a concrete segment? The maximum weight, dimensions (length, width, diameter), and surface characteristics (grease, temperature, roughness) will determine the design of the necessary grabs, hooks, or electromagnets. A design error here can be catastrophic.

2. Existing Cranes and Systems

The new material handling equipment must integrate perfectly with the current infrastructure. It is vital to know the capacity, operating radius, and type of hook of your cranes. In many cases, a custom design ensures that the material handling equipment not only fulfills its function but also maximizes the performance of the existing lifting system.

3. Production Flow

What is the frequency of use? Will the material handling equipment operate continuously, or only during peaks? Does the system need to rotate or tilt the load? The speed and sequence of the process will influence the choice between a manual, semi-automatic, or fully automated system.

4. Material Flow Pattern

A vertical flow pattern will require elevators, conveyors, pipes, etc., while the horizontal flow pattern will require trucks, bridge cranes, conveyors, etc.

5. Maintenance

High-quality material handling equipment translates into a lower total cost of ownership (TCO). Ask about maintenance cycles, spare parts availability, and the robustness of the design. Our material handling equipment is designed to withstand severe industrial environments.

6. Safety and Regulations

This is the pillar of any operation. Ensure that the manufacturer complies with international design and manufacturing regulations such as ISO 9001:2015 (Quality Management) and that the material handling equipment has CE certification and adheres to standards like EN 13155 (Lifting Accessories). A commitment to safety is a commitment to your human team.

Why choose us as a manufacturer of material handling equipment

With over 20 years of experience, we are a specialized manufacturer of custom-made MHE material handling equipment, designed to meet the most demanding industrial needs.

We offer:

- Custom design and manufacturing.

- Certified material handling equipment according to European regulations.

- Solutions for complex loads or critical processes.

- Technical support from engineering to commissioning.

Every piece of material handling equipment is designed with maximum safety, efficiency, and durability in mind.

Optimize your operations with advanced material handling equipment

Material handling equipment (MHE) is essential for any company that handles loads intensively. Choosing the correct solution improves productivity, reduces risks, and optimizes operating times.

If you need standard material handling equipment or a fully customized solution, we can design and manufacture the perfect handling system for your process. Request your project today.