Building wind turbines in the ocean is a reality that has turned offshore wind energy into a true renewable revolution. This is demonstrated by WindEurope’s data which, in its report ‘Offshore Wind Europe’, states that Europe has achieved the record of installing 3,148 MW of this technology in 2019, twice as much as in 2018.

We are in the golden age of offshore wind energy according to Giles Dickson, CEO of WindEurope:

‘Offshore wind is a very important part of renewable energy. Moreover, as costs have fallen rapidly, investing in this technology today costs no more than investing in conventional energy.’

Forecasts for the year 2030 for wind energy in the ocean indicate that there will be a global growth in this technology, with the possibility that the installed capacity will triple in 10 years.

Learn about the challenges wind energy offshore brings and get an overview of this industry that promises to continue ”downwind” for years to come.

Factors to take into account to implement wind turbines in the ocean

1. Roughness

The wind industry uses a scale to classify the roughness of the terrain. The rougher the terrain, the slower the wind. Thus, while a forest may have a level 3 or 4 roughness, the sea surface has almost no influence on the wind, being class 0. It’s clearer why installing wind turbines in the ocean is a good idea, right?

2. Wind variability

It is the fluctuation of the wind speed and therefore of its amount of energy. Normally the wind is stronger during the day since the difference in temperature between the sea surface and the land surface is greater.

3. Turbulences

Those who used to fly in an airplane already know this phenomenon. It is an irregular movement of the airflow that can be caused by storms or by areas of great roughness. Turbulence reduces the use of wind for energy production and wears out the wind turbines.

Related post: Know the differences between onshore and offshore wind farms

How to build offshore wind farms?

The installation of an offshore wind farm is a real challenge that involves several professionals and works, such as dredging the seabed, assembling, transporting and fixing the foundations, installing underwater cables…

These activities require specialized equipment and personnel, as well as support infrastructure. For all these reasons, the exploitation of wind energy has a high cost, but in spite of everything it continues to be an investment with a great return, both economically and environmentally.

Step 1: Fixing the turbines at sea

The wind turbines are fixed to the terrain by means of specific foundations for offshore wind turbines. The conditions of the terrain are taken into account, as well as the advantages and disadvantages of each type of foundation, since it has to support static loads (such as the weight of the wind turbine) and dynamic loads (bursts and earthquakes).

In addition to the choice of foundation, 3 methods can be used for stabilization on the seafloor:

- Taking advantage of gravity, in which the own weight of the foundation guarantees stability.

- Fix stakes to the seafloor by drilling into the ground.

- Anchor a floating platform to the seafloor, preventing it from moving.

Step 2: Choosing the best turbines

The wind industry has made investments to adapt conventional wind turbines for use in the ocean. The main differences are related to the materials used: they include protection against erosion, support systems for humidity, as well as reinforcements in the metal coating used in the machinery.

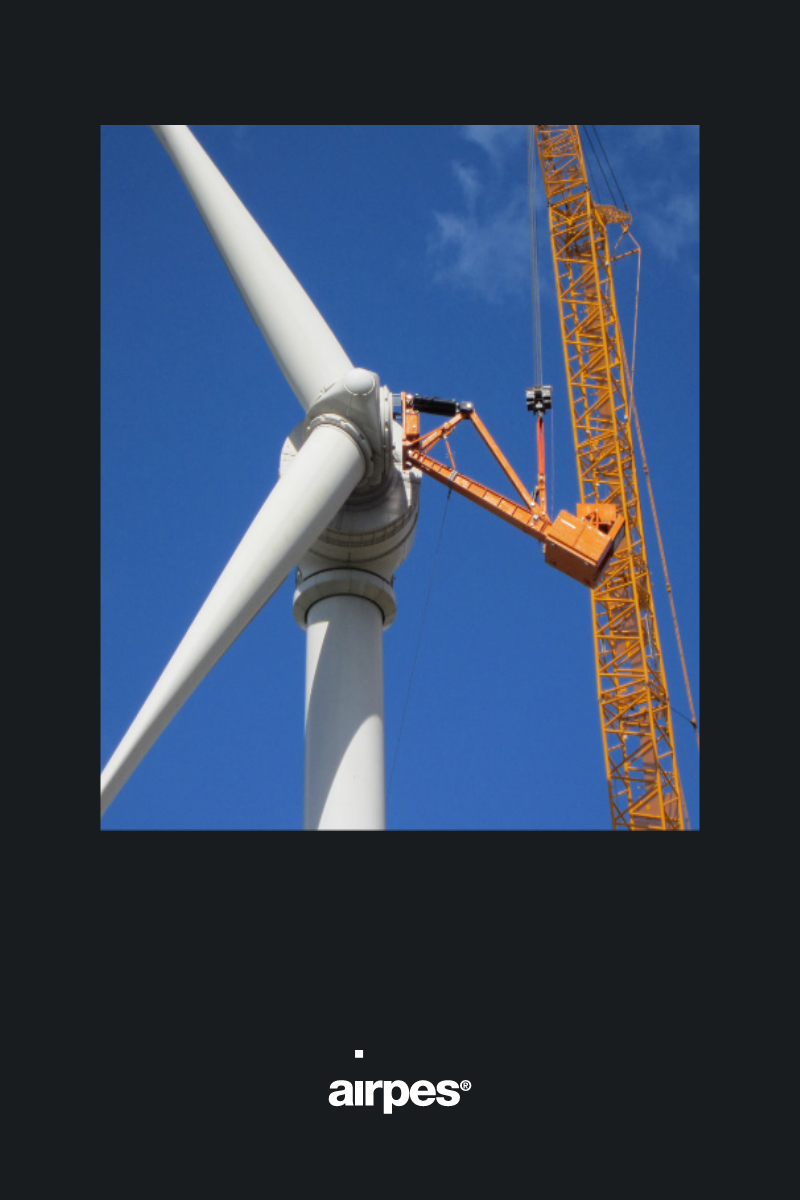

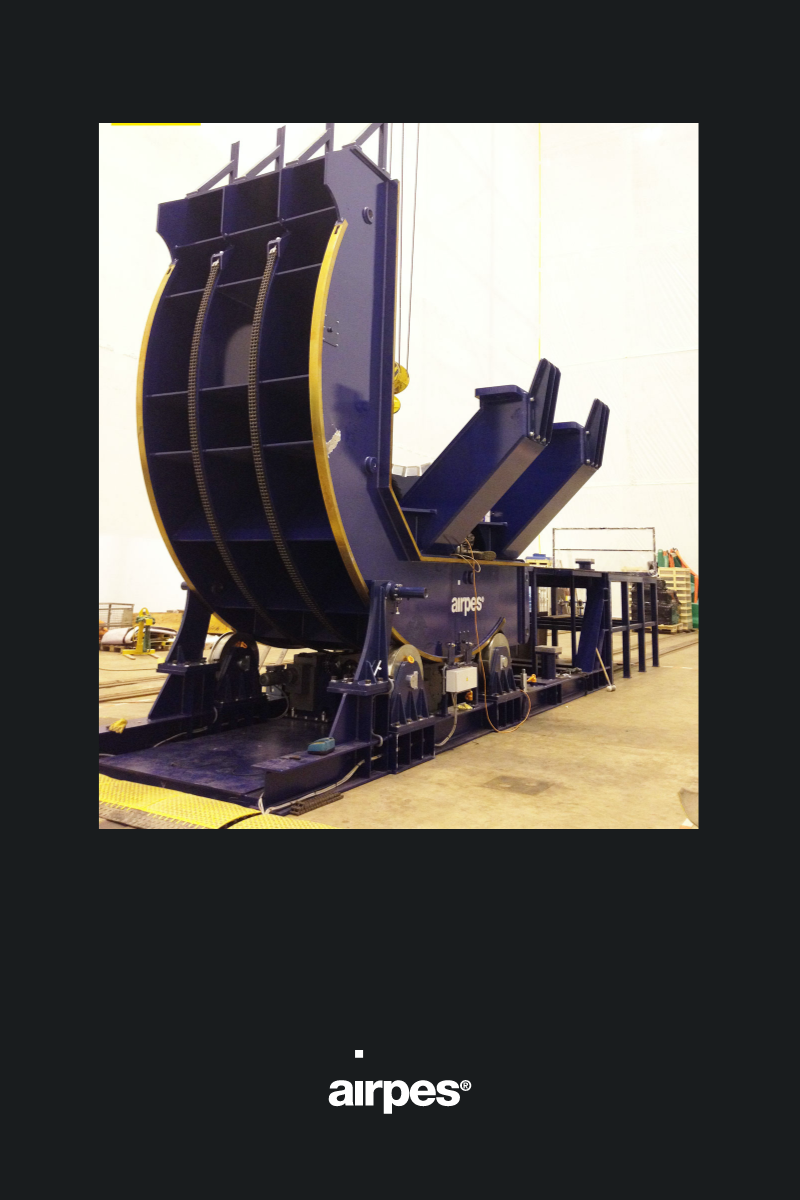

Transporting all the parts of a wind turbine and installing them at sea requires precision and safety. It is an engineering challenge that must often be met with on demand solutions for each project, such as those we can develop at Crosby Airpes.

Step 3: Bringing the energy to the ground

As we have seen, the production of wind energy in the ocean requires support structures for specific wind turbines and turbines that are capable of dealing with maritime conditions.

There are several electricity transmission systems, taking into account that offshore ones have quite restrictive installation, operation and maintenance conditions. The most used is the High Voltage Alternating Current Transmission Systems. This technology requires an underwater cable, an ocean substation, another station on land and a common connection point, in alternating current.

Once these conditions are guaranteed, the wind energy can be used to produce electricity that will be transported to the land and distributed through the electrical network to our homes.

Want to know more? How do you set up a wind farm?

Crosby Airpes solutions for the installation of windmills and wind farms at sea

Crosby Airpes offers you innovative tools that facilitate the installation of wind turbines at sea. We have more than 25 years of experience in the designing and manufacturing of weighing systems and handling equipment. This translates into quality products for the wind energy industry.

All Crosby Airpes products meet the strictest safety and quality standards of the European Union, in addition to having the design, manufacturing and marketing processes certified in ISO 14001:2015 and ISO 9001:2015 standards by the prestigious German organization TÜV.

On demand solutions for the installation of wind turbines in the ocean

Discover some of our on demand solutions developed specifically for offshore wind farm projects.