3 Steps when assembling a Wind Farm, a modern problem and the Crosby Airpes’ solution to it

Setting up a wind farm involves a great deal of work by technicians and engineers to make sure that everything fits perfectly and there are no failures. A wind turbine is made up of parts of colossal dimensions and high production costs. Any error in transport or assembly that causes damage to any of the parts will mean adding more time of return on investment. In this article we will briefly describe the steps to assemble a wind turbine on land without failures.

Step #1: Opening of roads and accesses

Before you can even begin to build the base for a turbine it is necessary to open entrances to the machinery. These roads will also serve for the passage of the special transports in charge of moving the different pieces that compose a wind turbine.

Step #2: Building a solid base and foundation

Logically, the initial phase of construction of any wind turbine begins with the foundation. The total weight of a wind turbine can easily exceed 100 tons, so it is extremely critical to build a solid and stable base that can support the entire structure.

Step #3: Tower and gondola assembly

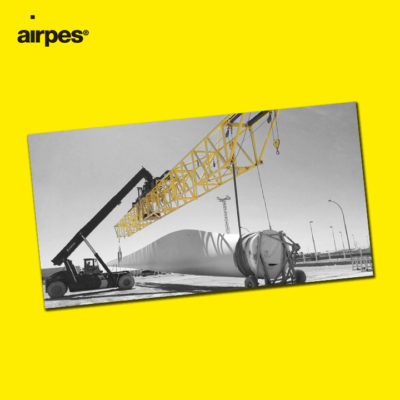

The wind turbine tower normally consists of two or three sections, which are usually assembled using heavy-duty cranes. The same cranes will be used to lift the nacelle and place it on top of the tower. In some cases it is also possible to lift the gondola in a modular way and in parts, depending on the type of wind turbine and the company that installs it.

The problem: the new giant wind turbines designed in the last decade are too big for a crane

Wind energy sector is creating bigger wind turbines (in height and rotor diameter) for the simple reason that the higher you go in the sky the most stable and powerful the winds are.

This means that given a specific spot, a higher and bigger rotor will generate more energy that a smaller one.

However, this increase in the size of the structures meant new challenges in logistics and assembly methods for engineers.

BIGGER generators meant BIGGER problems

The only method of lifting a very heavy wind turbine/blade was using bigger high-tonnage cranes that are really expensive

This high-tonnage crane had to be moved in-place for every turbine that you install, which takes a lot of time and money

Access roads built in Step #1 had to be even bigger given the massive size of this type of cranes (what means more cost)

Crosby Airpes solution for assembling wind turbines: craneless assembly of rotor and blades

When the tower and gondola are correctly assembled it is the turn to lift the rotor and then the blades.

A few years ago, when wind turbines were relatively small -which is less and less common- the rotor would be mounted with the blades already attached, but today we have large and heavy wind turbines, so lifting the rotor with its three blades already attached is an impossible task. It is a very large structure: tens of tons of weight that must be lifted to more than 100 meters high.

Save money on assembly costs of wind farms

In these cases the rotor is first lifted and installed and then the blades are attached to it one by one. Precisely to carry out this task, Crosby Airpes has designed a system for lifting wind turbines without a crane, using the structure and the tower of the wind turbine as a support. As well as simplifying the task we reduce the cost of assembly: the price per hour of renting a high tonnage crane is very high.

Experts in logistics for the wind energy industry

Check some of the projects we have designed for the wind energy industry: