A wind turbine is a sophisticated piece of engineering. Because of its size, its different parts are assembled on arrival at the wind farm. Each component has specific characteristics and requires specific tools to be transported or installed.

We will analyze the characteristics of each part of the wind turbine and what wind turbine equipment is necessary for their transportation, installation, and maintenance.

What are the main parts of a wind turbine?

A wind turbine consists of five major parts and many minor parts. The main components are the foundation, the tower, the rotor and hub (including three blades), the nacelle, and the generator.

The installation of all these elements requires specific wind turbine equipment to fulfill the needs of each one.

1. Wind turbine foundation

The foundation is in the ground for onshore turbines; it is invisible because it is covered with dirt. It is a large, heavy structural block of concrete that must support the entire turbine and the forces acting on it.

In offshore turbines, the foundation is underwater and not visible. For offshore turbines far from the sea, the base floats but has enough mass to support and sustain the weight of the turbine and any forces exerted on it.

You may be interested in: Difference between onshore and offshore wind farms

2. Wind energy tower

The towers of most modern turbines are made of round steel tubes. A rule of thumb for a turbine tower is that it is the same height as the circle’s diameter its blades make as they spin. Generally, the taller the turbine, the more susceptible to high-speed winds. Because the farther we are from the ground, the stronger the wind (the wind does not have the same speed at different heights).

Discover how to transport and install tower sections with our equipment.

-

Rotation & Installation Tower Section Tool

This tailor-made solution was developed to transfer directly from the harbor to the on-site tower section while providing the rotation…Rotation & Installation Tower Section ToolSeptember 22, 2020

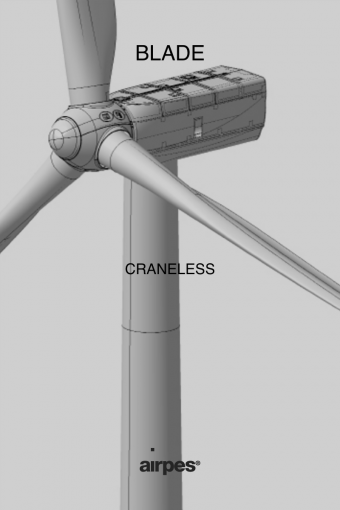

3. Wind turbine rotor and hub

The rotor is the rotating part of the turbine; it consists of three blades and a central part connecting the blades, the hub.

Although it is the most common, a turbine does not necessarily have three blades. But the three-blade rotor has advantages such as optimum efficiency. The blades aren’t strong; they’re hollow and made of composite material that’s both lightweight and strong. The trend is to make them bigger (for more power), lighter, and more robust. For aerodynamics, the blades are shaped like an airfoil (like an airplane’s wings). Also, they are not flat and have a twist between their root and tip. The blade can rotate up to 90° around its axis. This movement is called pitch.

The function of the hub is to hold the blades and allow them to rotate relative to the rest of the turbine body.

Crosby Airpes offers a wide range of solutions for the transport, installation, and maintenance of wind blades.

4. Wind turbine Nacelle

The nacelle houses all the components that need to be on top of the turbine.

The nacelle of a wind turbine is a complex electromechanical system with quite a few components that function correctly with precision. Significant turbine parts are the generator and the turbine shaft that transfers the harvested power from wind to the generator through a gearbox. The gearbox is an essential part of the wind turbine; it’s on the cable car.

Since the turbine must follow the wind and adjust its direction according to the wind direction, its rotor must turn relative to the tower. This rotation is called yaw motion, in which the nacelle and rotor rotate around the tower axis.

We adapt our nacelle lifting beams to your needs.

-

LIFTING NACELLE BEAM 59t

Airpes Nacelle tools for installation and transportation solutions vary in design, complexity, and capacity. This tailor-made solution was developed to…LIFTING NACELLE BEAM 59tSeptember 22, 2020

-

NACELLE LIFTING BEAM 160mTn

This nacelle lifting device for onshore is designed on demand of the client’s request, fulfilling airpes satisfactorily all the specifications.…NACELLE LIFTING BEAM 160mTnSeptember 22, 2020

-

NACELLE LIFTING BEAM 80mTn

This nacelle lifting device for onshore is designed on demand of the client’s request, fulfilling airpes satisfactorily all the specifications.…NACELLE LIFTING BEAM 80mTnSeptember 22, 2020

5. Wind energy generator

A generator is a component that converts the mechanical energy of the rotor (obtained from the wind) into electrical energy. The generator has the same structure as the electric motor.

You may be interested in: How to Assemble a Wind Turbine

Crosby Airpes is an expert in wind energy equipment

Setting up a wind farm onshore or offshore is no easy task, but it can be made easier with the right travel companion.

Crosby Airpes specializes in lifting solutions for the wind power industry. Each client has specific needs: the geographical location of the wind farm, the characteristics of the equipment, etc., which make each project unique.

At Crosby Airpes, we have extensive experience designing lifting systems, and we are ready to assist your business in the wind energy sector. Contact us and let us know how we can help you.