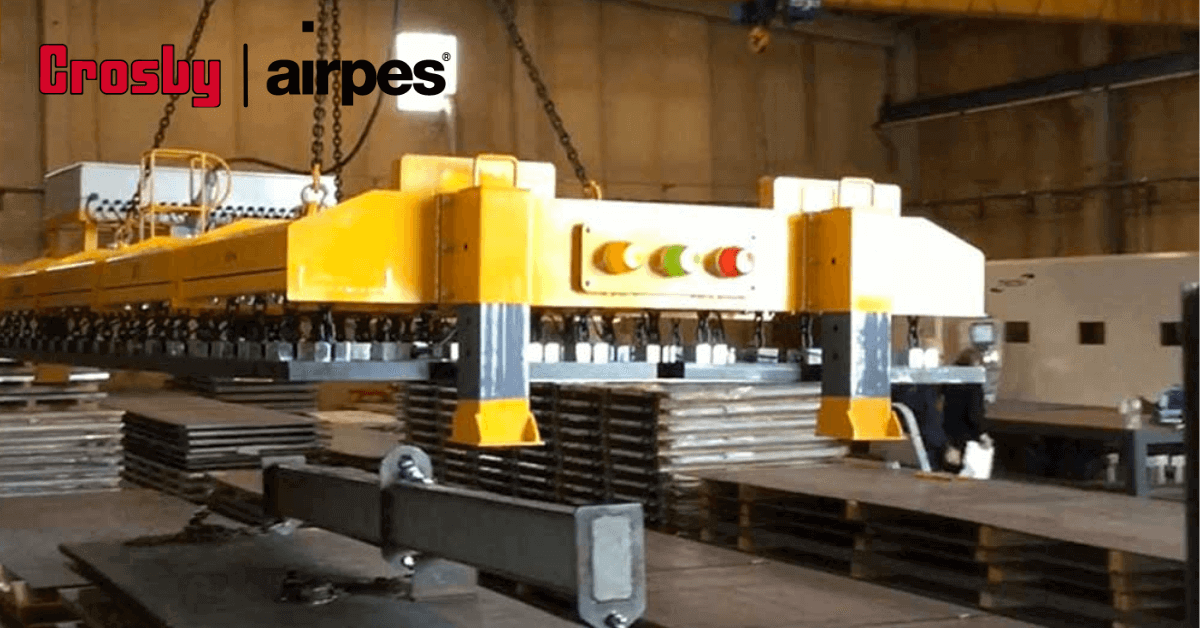

Applying electromagnets helps us to lift metal elements and transport them comfortably and quickly. They provide a practical and convenient solution for steel plates (hard to move with other heavy lifting equipment).

At Crosby Airpes, we have broad experience in lifting solutions that use electromagnetic forces to handle metal grids, steel plates, beams, etc. Today, we are going to review 5 safety tips for electromagnets’ uses.

See our permanent magnets in action!

The best safety tips for electromagnets’ uses

The first piece of advice is to choose a reliable machinery supplier with the necessary permits and inspections in order to ensure that your business and productivity are not adversely affected.

1. Define the type of plates you want to lift

All factors that help us determine the permanent electromagnet’s operation must be considered. The number of plates to be lifted, their weight or the surface conditions on which they are located are essential details.

And remember, with an electro lifting magnet, you can adjust the strength by varying the amount of electric current that is fluent. That can help you to lift heavier or lighter metal plates.

For example, if some of the materials create an air gap between the magnet and the plate, this will impact the lifting.

2. Check potential hazards in the environment

The two primary hazards of electromagnet lifting are falling elements, common in all lifting projects, and electromagnetic fields. Even a active body implant can experience interference from the electromagnetic field that the machine generates. Keeping it in mind and keeping a safe distance will make it safer.

3. Protect your business and your lifting system from power failures

If power is interrupted, an electromagnet will not release the load. But it’s always essential that you check your system. At Crosby Airpes, We give at least 20 extra minutes of power supply by the battery.

4. Check the electromagnets before uses

In addition to electrical problems, you must never forget to overhaul the lift system. You can create a checklist that you can check every time the electromagnet is used. You can only start using the equipment once all the requirements are met.

When magnets are attached to cranes or forklifts, operators can lift and move metal objects. This makes the job easier and lowers the risk of injuries.

5. Choose the permanent electromagnet that best suits your project

You will probably have in mind some permanent electromagnets’ uses for your project because each company and each project has its own needs (and if this project involves moving metal pieces, you would probably need it). Ensure that your equipment is ideal for handling the load in each case, and always follow the safety instructions provided by the manufacturer.

You may be interested in: 10 safety precautions when using lifting equipment

Crosby Airpes provides you with the electromagnet lifting equipment you need

At Crosby Airpes, we help you find the lifting system that best suits you to work as safely as possible.

Do you have specific needs? We adapt to them with our on-demand solutions.