In industrial operations, lifting and transporting heavy steel plates is far from straightforward. Without a proper steel plate lifter, companies risk material damage, operator injury, and production inefficiencies. These challenges are especially common in steel service centers, shipyards, and heavy manufacturing facilities.

At Crosby Airpes, we engineer solutions that go beyond the catalog. Each plate lifting device is designed to fit the real conditions of your facility — whether you’re lifting flat carbon steel sheets, curved sections, or heavy composite plates.

This guide outlines the key challenges of steel plate handling and the lifting systems Crosby Airpes manufactures to solve them.

What is a steel plate lifter?

A steel plate lifter is a purpose-built lifting system designed to move flat steel plates safely and evenly using an overhead crane or gantry. Unlike basic lifting hooks or chains, these devices prevent flexing, distribute loads properly, and reduce the risk of material deformation or accidents.

The term plate lifting devices refers to a wider group of technologies — including magnetic systems, spreader beams, and hybrid solutions. Crosby Airpes designs and manufactures all these systems in-house, ensuring a custom fit for each client.

You may be interested in: sheet lifters for heavy steel plate handling

Common challenges in plate lifting

Every industrial environment is different, but some problems come up consistently when lifting large steel plates:

- Unbalanced loads causing instability during lifts

- Surface damage due to poor contact points or clamp pressure

- Incompatibility between lifting tools and existing cranes

- Limited headroom in indoor facilities

- Lack of traceability when weight monitoring is required

- High product variability that demands flexible lifting configurations

These problems often arise when using generic tools instead of systems designed for your actual workflow.

Our solutions for steel plate lifting

We offer a range of steel plate lifting systems engineered for real industrial demands. All systems are built with safety, process integration, and long-term durability in mind.

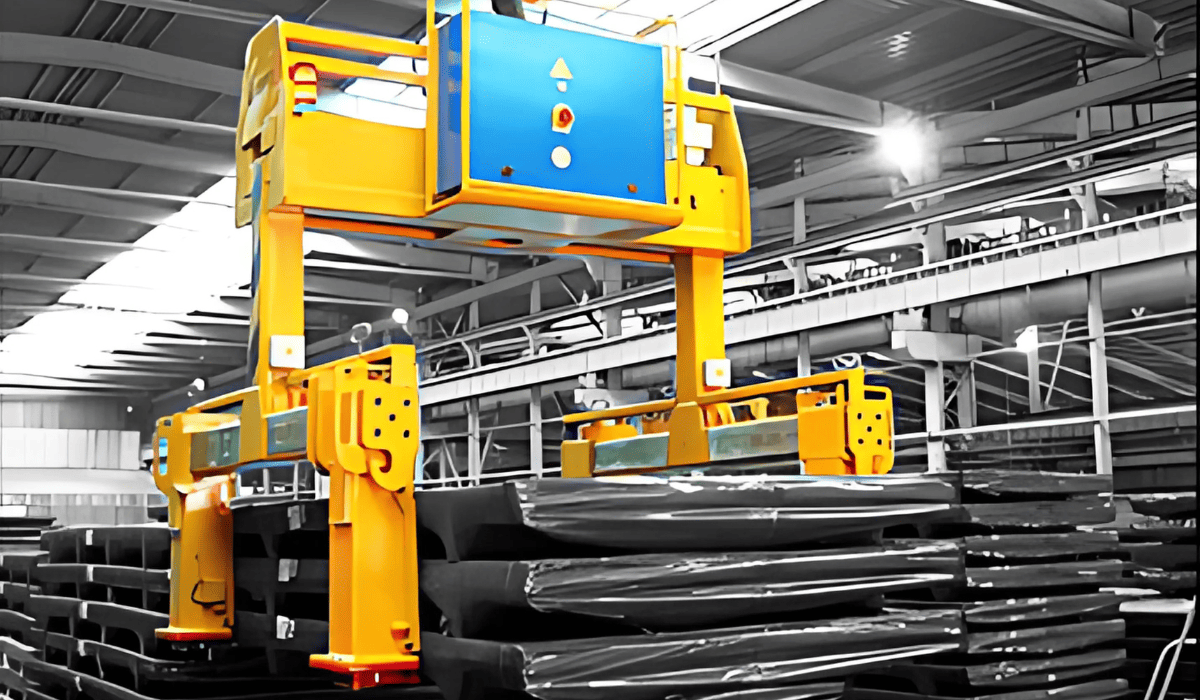

Magnetic lifting systems

Our electro-permanent lifting magnets are ideal for handling steel plates without damaging the surface. These systems are designed for high-throughput operations and include:

- Redundant safety features

- Load and fault detection

- Visual and audible alerts

- Manual or automatic release functions

- Optional weighing integration

Custom lifting beams and spreader beams

When magnetic lifting is not viable — due to plate shape, weight, or safety policy — Crosby Airpes designs custom lifting beams that evenly distribute load over multiple lift points. These beams are ideal for:

- Irregular or large-format plates

- Lifting multiple plates at once

- Use in low-clearance environments

- Integration with existing cranes and controls

Vacuum sheet lifters (selective use)

For applications that require non-magnetic handling, we offer vacuum sheet lifters in specific use cases. These are typically used where surface finish or cleanliness is critical, and they are designed with redundant vacuum pumps and sensors.

If you are interested in learning more about vacuum sheet lifters, please read our article “Vacuum sheet lifters: advantages and recommendations for use”

Integrated lifting + weighing

A key differentiator at Crosby Airpes is our ability to build lifting systems with integrated weighing. This provides:

- Real-time weight data

- Fewer handling steps

- Improved process traceability

- Compliance with production reporting requirements

Weighing modules can be added to magnetic lifters or beam-based systems.

How to select the right plate lifting device

Selecting the right steel plate lifter isn’t just a matter of load capacity — it’s about ensuring compatibility with your processes, reducing handling time, and increasing safety and repeatability in your operations.

Whether you’re running a steel service center, a fabrication line, or heavy industry production, here’s what you should always consider:

-

Load size, shape and flexibility

Start with the actual plate dimensions and weight ranges. For example:

- Are you lifting small, thick plates or large, flexible sheets?

- Do you handle a wide variety of formats, or just a few standard sizes?

- Do the plates sag when lifted from a single point?

Plates that bend or flex need support across their length — this typically points to a spreader beam solution or a multi-magnet lifting frame.

-

Load distribution and center of gravity

Poor load balance is a leading cause of swinging or tilting plates, especially when handled by inexperienced operators. Your lifting device should:

- Account for off-center gravity

- Include multiple pick points (with adjustable spread if needed)

- Ensure symmetrical lifting, especially on large formats

If load shift is common in your operations, consider a beam with pivoting lifting points or adjustable hangers.

-

Crane system integration

You’re not just buying a lifter — you’re integrating it into your existing crane system, which may have limitations like:

- Low overhead clearance

- Limited hook travel or coverage

- Older hoists or pendant controls

- High-duty cycles (24/7 operations)

Our engineering team evaluates these constraints to deliver tailored lifting beams or magnetic frames that won’t interfere with crane paths or limit productivity.

-

Surface protection requirements

Some applications — like stainless steel, pre-coated plates, or polished surfaces — require contact-free lifting to avoid scratches or marks. In these cases:

- Magnetic lifting systems with optimized flux control are ideal

- Vacuum lifters can be used when magnets are not suitable

- Clamp or chain-based lifting should be avoided

If traceability is also a factor, we can integrate load cells to weigh and log each lift.

-

Frequency of use and automation level

If you’re lifting plates occasionally, a simple manual beam may suffice. But for high-throughput environments:

- Automation or remote operation becomes critical

- Fast cycle times demand quick-release magnetic systems

- Redundant safety features reduce downtime and manual checks

- Integrated weight sensors help with batch control

Let the data guide the choice: How many lifts per shift? How much time do you spend attaching, detaching, or repositioning slings?

-

Regulatory compliance and traceability

Finally, the lifter you choose must meet both technical specs and regulatory standards. Depending on the market and customer requirements, our equipment can be supplied to comply with:

- The EU Machinery Directive 2006/42/EC and its relevant harmonized standards, when marketed in Europe

- EN 13155:2020 (Nonfixed load lifting attachments), which defines safety requirements for equipment such as lifting beams, magnets, clamps and vacuum lifters.

- EN 602041:2019 for electrical safety, when the system includes motorized or electrical components

- Regulation (EU) 2023/1230 on machinery, which introduces updated requirements in the European machinery framework.

- OSHA regulations (for operations in the U.S.), including requirements for proof testing and marking of custom lifting accessories before use under §1926.251(a)(4)

All systems can be delivered with full documentation, test certificates, CE marking or equivalent compliance marks, declared conformity documents, and traceable inspection records. These certifications help you satisfy internal audits, insurance requirements, and regulatory inspections.

Let’s talk

Whether you’re lifting a single plate size or managing a wide range of formats, selecting the right system can transform your production workflow — reducing cycle times, improving operator safety, and ensuring compliance.

At Crosby Airpes, we don’t just supply lifting equipment — we design and manufacture systems tailored to your real-world requirements, with full integration into your crane, control systems, and quality processes.

Contact our team to explore how a steel plate lifter engineered for your facility can make a measurable difference in performance, safety, and reliability.