Industrial scale safety is a critical concern in facilities where heavy loads are handled daily. In the United States alone, workplace incidents involving lifting equipment and weighing systems result in thousands of injuries annually, many of which could be prevented through proper safety protocols and equipment installation.

When you use a crane scale to suspend massive or weighty loads and measure their weight within the workplace, you’re dealing with equipment that serves a dual purpose: precision measurement and load handling. This equipment helps minimize some risks associated with handling heavy loads because it simplifies the process of lifting and weighing and reduces the time spent transporting loads from one place to another to measure them.

However, since crane scales and other industrial weighing solutions help you carry heavy-duty material, you must consider additional safety measures to avoid any accidents regarding personal injury or goods damage. This comprehensive guide covers essential industrial scale safety protocols, from installation to daily operation, ensuring your facility maintains the highest safety standards.

Understanding industrial scale safety in high-risk environments

Industrial scale safety encompasses more than just operating weighing equipment correctly. It involves understanding the unique hazards in facilities where heavy loads, suspended materials, and precision measurements intersect. Construction sites, manufacturing plants, logistics centers, and heavy industry facilities each present distinct challenges requiring specialized safety approaches.

What makes industrial weighing particularly hazardous:

Suspended load control measures become critical when dealing with crane scales because the load remains airborne during weighing. Failure at this stage can result in falling objects, equipment damage, and serious injuries.

Heavy duty scale installation requires careful planning and execution. According to OIML R 76-1 international standards, proper installation is foundational to both measurement accuracy and workplace safety. An improperly installed scale can shift during operation, create tripping hazards, or provide inaccurate readings leading to overloading situations.

Environmental factors including temperature extremes, corrosive atmospheres, dust, and moisture can compromise both equipment integrity and operator safety if not properly addressed through equipment selection and maintenance protocols.

Crane scales require particular attention because they handle suspended loads, making them inherently more dangerous than floor-based weighing systems. The consequences of equipment failure or operator error are significantly more severe when the load is airborne.

Critical safety factors for crane scales installation

Before using a crane scale, you must ensure the equipment has been installed appropriately. Installation must follow manufacturer specifications and comply with safety measures. Proper installation prevents problems, malfunctions, and accidents.

Professional crane scales installation involves:

Structural assessment: The mounting point must support the maximum rated capacity plus the heaviest anticipated load. This typically requires structural engineers to verify load-bearing capacity.

Proper rigging: Connections between the crane hook and scale, and between scale and load, must follow manufacturer specifications. Incorrect shackles, hooks, or attachment points compromise system safety.

Electrical safety: For digital crane scales, proper grounding and electrical hazard protection must be ensured. Wireless systems require sealed battery compartments protected from environmental contamination.

Calibration verification: After installation, scales must be calibrated using certified test weights to ensure accuracy across the full operating range. This is essential for both measurement precision and safety, as inaccurate readings lead to overloading.

Environmental considerations: Installation must account for temperature variations, humidity, vibration, and electromagnetic interference affecting scale performance or safety.

Pre-operation safety protocols

Before each use of crane scales or lifting scales, operators should conduct comprehensive pre-operation inspection:

- Visual inspection: Examine the scale body, shackles, and hooks for damage, cracks, deformation, or corrosion. Replace any compromised component before use.

- Function test: Power on the scale and verify display function. Ensure adequate battery levels or secure power connection for digital systems.

- Zero verification: Confirm the scale reads zero when unloaded. Persistent non-zero readings indicate calibration drift or mechanical issues.

- Load limit confirmation: Verify the scale’s maximum capacity and ensure the anticipated load falls well within safe operating limits.

- Documentation review: Check that recent calibration is current and all required crane scales inspection records are up to date.

- Environmental assessment: Evaluate wind (for outdoor operations), temperature, and other factors that might affect safe operation.

Six essential safety measures during crane scale operation

Let’s review six basic safety precautions to keep in mind when using a crane scale.

1. Ensure your crane scale is installed properly

Before using a crane scale, you must ensure that the equipment has been installed appropriately. The installation must follow the rules and necessities the manufacturer sets out in the relevant handbook and comply with safety measures. A proper installation will avoid problems, malfunctions, or accidents.

Integration with monitoring and overload protection systems provides additional safety by preventing accidental overloading and providing real-time operational data.

2. Only allows your trained workers to be the ones using the crane scale

Only professionally trained personnel can operate crane scales safely. Heavy machinery needs knowledge and skills to be used safely, and crane scales are no exception.

Comprehensive operator training should cover:

- Understanding load capacity limits and safety factors

- Proper load attachment and rigging techniques

- Reading and interpreting scale displays accurately

- Recognizing signs of equipment malfunction or damage

- Emergency procedures and proper shutdown protocols

- Communication procedures with other personnel during lifting operations

Training should be documented, and operators re-certified periodically to ensure skills remain current.

3. Train your team in risk prevention

Training in occupational risk prevention is a must in every business, and it’s even more critical in environments where big loads must move around. Ensure your team has the training to keep from suspended loads and know the risks when operations occur.

Risk prevention training should address:

- Hazard identification: Workers must recognize potential dangers including overhead hazards, pinch points, and swing radius of suspended loads.

- Suspended load control measures: Understanding load dynamics including swing, rotation, and effects of wind or sudden movements is essential for safe operations.

- Safety zone establishment: Clear demarcation and enforcement of exclusion zones around active lifting operations prevent unauthorized personnel from entering dangerous areas.

- Communication protocols: Establish clear hand signals, radio communication, or other coordination methods between operators, riggers, and personnel.

- Emergency response: All personnel should know procedures for equipment failure, load slippage, or other emergencies, including evacuation and emergency shutdown.

4. Never pass under a suspended load

You should never go underneath a load suspended during the weighing process. If the load falls, it can cause severe injuries (such as broken bones) and property damage.

Remember that equipment can fail due to material fatigue, hidden defects, or extreme conditions. The suspended load exclusion zone is your last defense against catastrophic injuries.

5. Never exceed the maximum load limit of the scale

To avoid breaking a crane scale, never exceed their maximum load limit. You have to know the exact load limit of your equipment and ensure you never trespass it. To obtain an accurate reading, you must stay within the suitable capacity; otherwise, you may damage the measuring element or the hook. If the hook is damaged, it can cause the load to fall (and consequent injuries and damage).

Understanding and respecting load limits involves:

- Know your scale’s capacity: Maximum capacity should be clearly marked on equipment and documented in operating procedures, readily accessible to all operators.

- Apply safety factors: Best practice dictates operating at no more than 80-90% of maximum capacity regularly, reserving full capacity for occasional, controlled situations.

- Consider dynamic loads: Sudden movements, swinging, or shock loading create forces significantly higher than static weight. Allow extra margin for dynamic factors.

- Account for rigging weight: Total load includes the material being weighed plus slings, shackles, spreader bars, and other rigging equipment.

- Implement overload protection: Modern weighing systems can be equipped with automatic overload cutoffs preventing operation when loads exceed safe limits, providing additional safety against human error or miscalculation.

6. Performs periodic maintenance and inspections of the crane scale

Please ensure your weighing equipment, such as your crane scales, is inspected regularly to check for malfunctions or inaccurate readings. Periodic inspection and maintenance are mandatory to guarantee safety for your team. Moreover, it will be the only way to ensure the weighing data’s accuracy over time.

You may be interested in: The benefits of using a crane scale

Common safety hazards and prevention

1. Equipment overloading

Risk: Exceeding rated capacity causes catastrophic failure of the scale, hooks, or rigging, resulting in load drops.

Prevention:

- Clearly mark all equipment with maximum capacity ratings

- Train operators to estimate load weights and apply safety factors

- Install overload protection systems

- Implement permit systems for loads approaching maximum capacity

- Regular calibration for accurate weight readings

2. Component failure due to wear

Risk: Fatigue cracks, corrosion, or impact damage weaken components, leading to unexpected failure.

Prevention:

- Establish rigorous inspection schedules

- Replace components at or before recommended service intervals

- Remove damaged equipment from service immediately

- Use appropriate materials for operating environment

- Maintain detailed maintenance logs

3. Human error in operation

Risk: Incorrect rigging, misreading displays, or failure to follow procedures leads to accidents.

Prevention:

- Comprehensive operator training and certification

- Clear, written standard operating procedures

- Supervisory oversight of critical operations

- Pre-operation checklists

- Regular refresher training

4. Adverse environmental conditions

Risk: Wind, rain, extreme temperatures, or poor visibility compromise safe operations.

Prevention:

- Establish weather-related operational limits

- Provide environmental protection for equipment

- Schedule critical lifts during optimal conditions

- Use warning systems for changing conditions

- Select equipment rated for expected environmental conditions

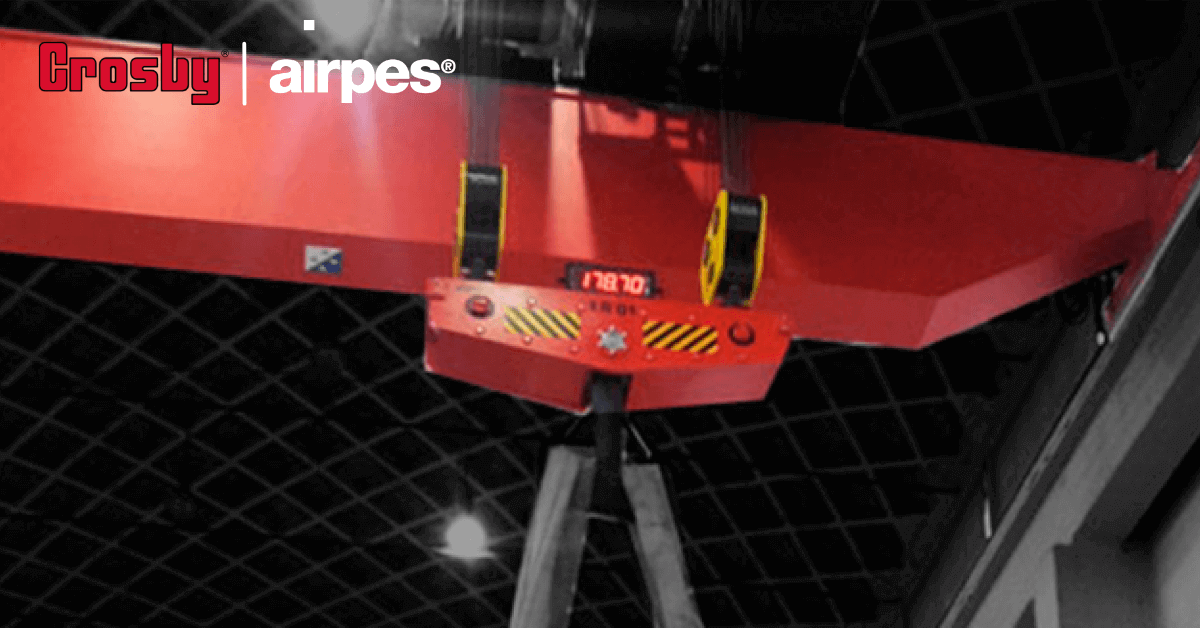

Discover Crosby Airpes crane scale solutions

-

HOOK BLOCK SCALE ATP-100

The ATP hook block scale is an electronic weighing system of great precision, thought to be adapted to any type…HOOK BLOCK SCALE ATP-100November 15, 2020

-

ELECTRONIC CRANE SCALE AGE-120

The AGE-120 electronic crane scale has been designed to be hung up from the hook of the overhead traveling crane,…ELECTRONIC CRANE SCALE AGE-120September 22, 2020

-

ELECTRONIC CRANE SCALE AGM-180

The electronic crane scale AGM-180 has been designed to be hung up from the hook of the overhead traveling crane,…ELECTRONIC CRANE SCALE AGM-180September 22, 2020

Our safety-first approach

At Crosby Airpes, we design and manufacture crane scales with safety as our primary concern. Our equipment incorporates multiple safety features and exceeds international standards.

¿Do you need a crane scale? We can design and manufacture crane scales to control the entrance and exit of items, storage control, stock control, and other actions.

Our measurement equipment can reset the tare, display the weight in kilograms or pounds, send the weight information via radio, and even use an infrared control system. Calibration is accurate, every single scale is easy to operate, and every model complies with all safety standards.

We can manufacture a new crane scale with a hook from scratch or add a scale to your previous hook. We adapt to your needs.

FAQS

How often should crane scales be calibrated?

Crane scales should be calibrated annually at minimum by qualified technicians. More frequent calibration may be required depending on usage intensity, regulatory requirements, or if the scale has been subjected to impact, overload, or suspected damage. Quarterly verification checks with certified test weights are recommended for high-use applications.

What is the most critical safety precaution when using crane scales?

Never passing under a suspended load is the most fundamental rule. This exclusion zone is your last defense against catastrophic injury if equipment fails. Additionally, never exceeding the maximum load limit is equally critical, as overloading is a primary cause of equipment failure.

Can crane scales be used outdoors in all weather conditions?

This depends on the specific model and environmental rating. While many crane scales are designed for outdoor use with appropriate IP ratings, extreme conditions like high winds, lightning, or severe cold can compromise safe operation. Always consult manufacturer guidelines for environmental operating limits.

What training is required to operate industrial crane scales?

Operators should receive comprehensive training covering load capacity understanding, proper rigging techniques, accurate display reading, equipment inspection procedures, emergency protocols, and relevant safety regulations. Training should be documented and operators re-certified periodically.