An industrial crane is an equipment designed to lift and lower materials, industrial equipment, and all related to heavy loads. They are used on construction sites to load materials, in seaports to move freight, and in iron and steel factories.

An industrial crane is an equipment designed to lift and lower materials, industrial equipment, and all related to heavy loads. They are used on construction sites to load materials, in seaports to move freight, and in iron and steel factories.

To have an industrial crane with remote control, you need to look for the best market option that allows you the opportunity to install a remote control system in your crane.

The parts of a crane you need to know to understand the remote system

When we talk about industrial crane remote control system and all that it brings to a company’s productivity, it is necessary to know and understand their movement. It is much easier to see if you know the parts that make up the cranes:

Concrete foundation: A tower crane always starts in this part, where the anchors are placed to fix the crane to the ground. After the foundation, the crane is lifted with the tower or mast.

Turntable: this is the part of a crane that allows it to rotate 360 degrees. And near this area, the operator’s cab is located, where the operator controls the crane with a full view. Above the cab is the tower peak or apex, where the pendants extend to support the jib.

It also supports the counter jib, located behind the cab, where the counterweights are placed to stabilize the crane during rest and movement. At the rear, the main winch and the motors are located.

In the body of the crane, where you find the Jib, the horizontal section, with a trolley and hook block to move the loads along the crane.

Best way to improve a crane: industrial crane remote control system

Remote control: the best upgrade for any crane or lifting system

To improve your productivity, speed of movement, and management of your machinery, installing a wireless control system to it. We can install an AUTEC remote control system to new lifting equipment or adapt it to an existing overhead crane. In any case, we will help you.

A transmitter for remote control of your cranes will not only allow you to control your crane from a distance and receive information – weight, temperature, ID code of the item…- from the load.

The advantages of using industrial crane remote control

- Safety: correctly using an industrial crane with remote control reduces the possibility of accidents since the operator can be out of the cab while controlling the power.

- Productivity: thanks to the remote control, work is done faster and more efficiently, improving productivity.

- Process Modernization: allows companies to improve their competitiveness in the market by incorporating systems that enable them to improve the production process.

- Cost Savings: as a result of the advantages mentioned above (safety, productivity, and process modernization), cost savings are generated, which translates into benefits for companies.

All you need to know about industrial remote control system

With overhead cranes and hoists, one of the most significant risks is that the operators are often near the load. Crane remote control systems offer the flexibility needed for an operator to get the best point to see the crane and the load. This advantage allows a complete vision to analyze any risk and act precisely and effectively.

In addition, it also allows operators to perform more tasks when they are not moving a load as they are not confined to the crane cab. This way, getting a more productive and profitable job is possible.

Wireless system for Autec: best option in the market

AUTEC designs radio industrial remote controls and systems for overhead industrial cranes, lifting equipment, logistics, construction… Crosby Airpes is a specialist in installing and adapting industrial radio control systems from the renowned manufacturer AUTEC to any crane or lifting system.

It is a Italian company with a product portfolio that includes a wide range of power solutions, tried and tested. Autec products and solutions are directly for original equipment manufacturers.

We are an official Autec distributor since 2003 through our own worldwide network

Since 1986 Autec has designed, manufactured, and delivered wireless control systems specifically for safety applications. They have a wide variety of controls, with only buttons, joysticks, or regulators and joysticks so that the machinery can perform many functions. It will allow the crane or hoist to achieve the exact movements the customer needs.

Innovative design, robustness, safety, and reliability have always been the hallmarks of our radio remote controls, which are used in countless applications like:

- Industrial overhead cranes

- Truck-mounted and construction cranes

- Elevating work platforms for the lifting of material and personnel

- Construction and maintenance machinery

- Factory automation

- Machines and systems for logistics and manufacturing processes.

To check out the complete wireless control systems, you may visit Autec’s website. If you need help or assistance with a new industrial crane remote control system, contact us and request a quote, and we will help you find the best safety remote control.

Qualified personnel in charge of remote control of cranes

While it is true that having a remote control in industrial cranes has benefits that directly affect the company’s economy, it is also essential to take into account the need for qualified personnel to perform the control work.

Safety is the fundamental value that a company must give to its employees. Depending on the type of crane, there is specific training to qualify its use. There are different types of cranes: tower, self-propelled mobile, self-loading, bridge, and gantry, among others. The person in charge must have a crane operator’s license, and accredited organizations give different courses.

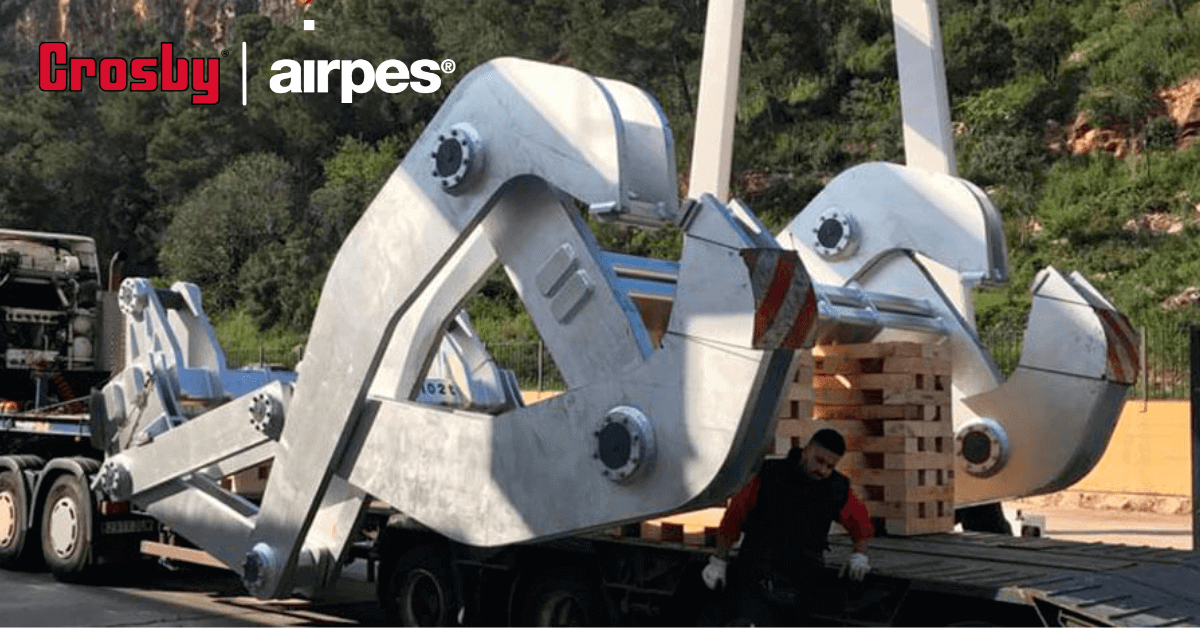

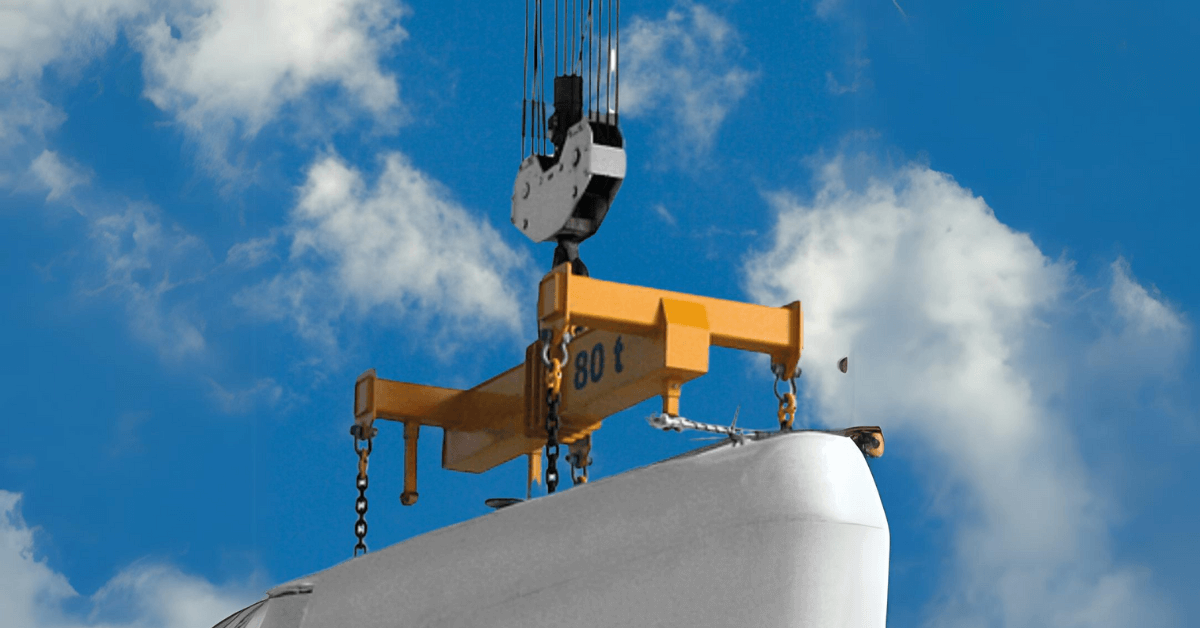

Here are some examples of lifting devices where we can install an industrial crane remote control system:

-

C-HOOK

Get to know our C-hook, designed to meet every customer's specific requirements for load configuration, weight, lifting area and headroom.…C-HOOKSeptember 22, 2020

-

SHEET LIFTER

Discover our sheet lifter that provides fast and smooth leg adjustment and allows for additional force to be applied to…SHEET LIFTERSeptember 22, 2020

-

LIFTING BEAM

Airpes offers many types of lifting beam designs, some of them are fixed beams, H beams, the moveable center of…LIFTING BEAMSeptember 22, 2020

-

SCISSOR LIFTING TONGS

Scissor lifting tongs are designed and manufactured by Airpes to lift and handle different types of loads. Our slab lifting…SCISSOR LIFTING TONGSSeptember 22, 2020

-

PAPER COIL TONG

Handling big amounts of paper can be difficult. If you need to move paper rolls up to 5 tons, this…PAPER COIL TONGNovember 26, 2020