If you’re handling loads that need to be repositioned, flipped, or rotated during manufacturing, assembly, or maintenance, you already know how critical it is to do it safely and efficiently. The wrong approach means downtime, safety risks, and costly damage to the load itself.

This guide breaks down everything you need to know about industrial load turning devices: how they work, how to choose the right one, and what makes the difference between a standard solution and one that’s truly built for your operation.

What Is an Industrial Load Turning Device and Why Does It Matter?

An industrial load turning device is a piece of lifting and handling equipment designed to rotate, tilt, or flip heavy loads (either suspended from a crane or resting on the ground) in a controlled and repeatable way.

The core challenge it solves: loads don’t always arrive in the orientation you need them. Turbine components, structural steel, large fabricated parts, pressure vessels… all of these require repositioning at some point in the process. Without the right equipment, teams resort to improvised rigging setups that are slow, inconsistent, and above all, dangerous.

A well-engineered industrial load turner eliminates that risk. It standardizes the operation, reduces handling time, and protects both the load and the people around it. And when you’re dealing with extreme weights or complex geometries, the right industrial load turner can be the difference between a smooth workflow and a serious incident.

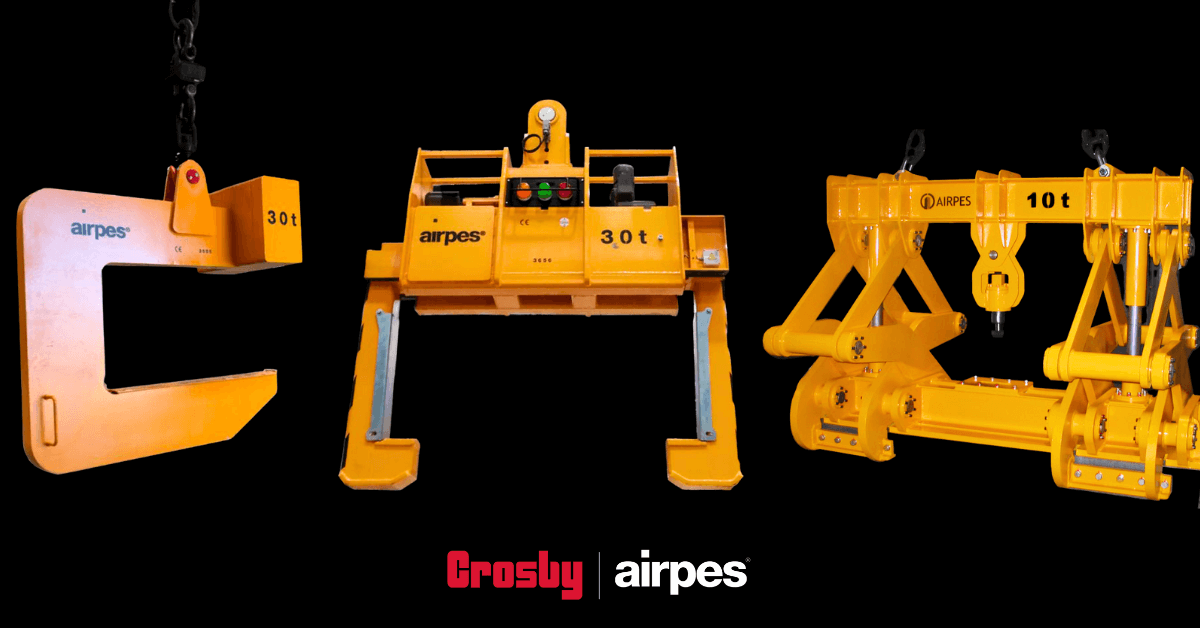

Types of Industrial Load Turners We Design and Manufacture

Not every rotation challenge is the same and that’s exactly why we don’t offer one-size-fits-all products. Here’s a breakdown of the main solution types we engineer:

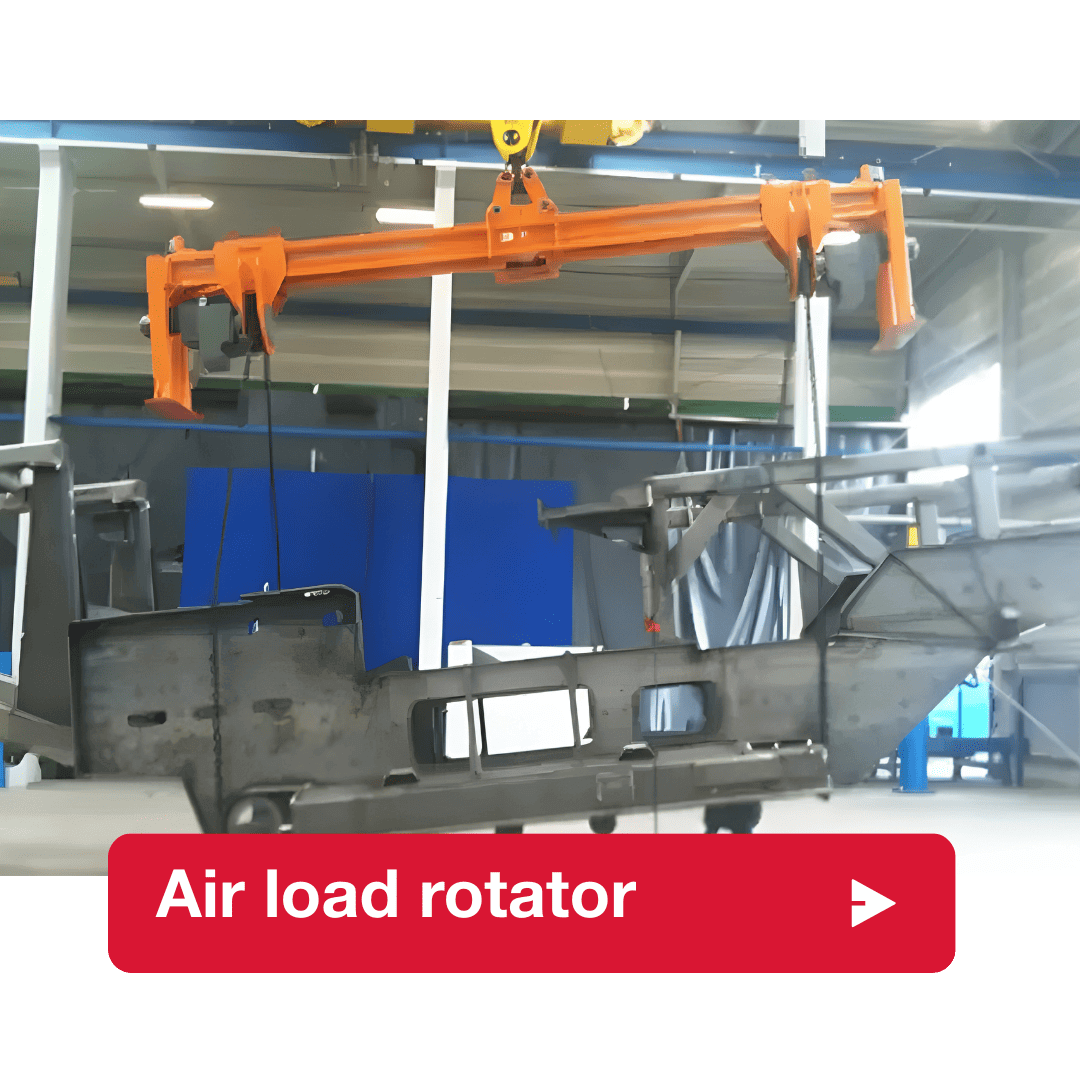

Air-Powered Load Rotators (Overhead)

These systems attach between the crane hook and the lifting accessories, allowing the load to be rotated 360° while suspended. They’re ideal for applications where the load needs to be repositioned mid-air before placement (think large fabricated components or wind energy parts).

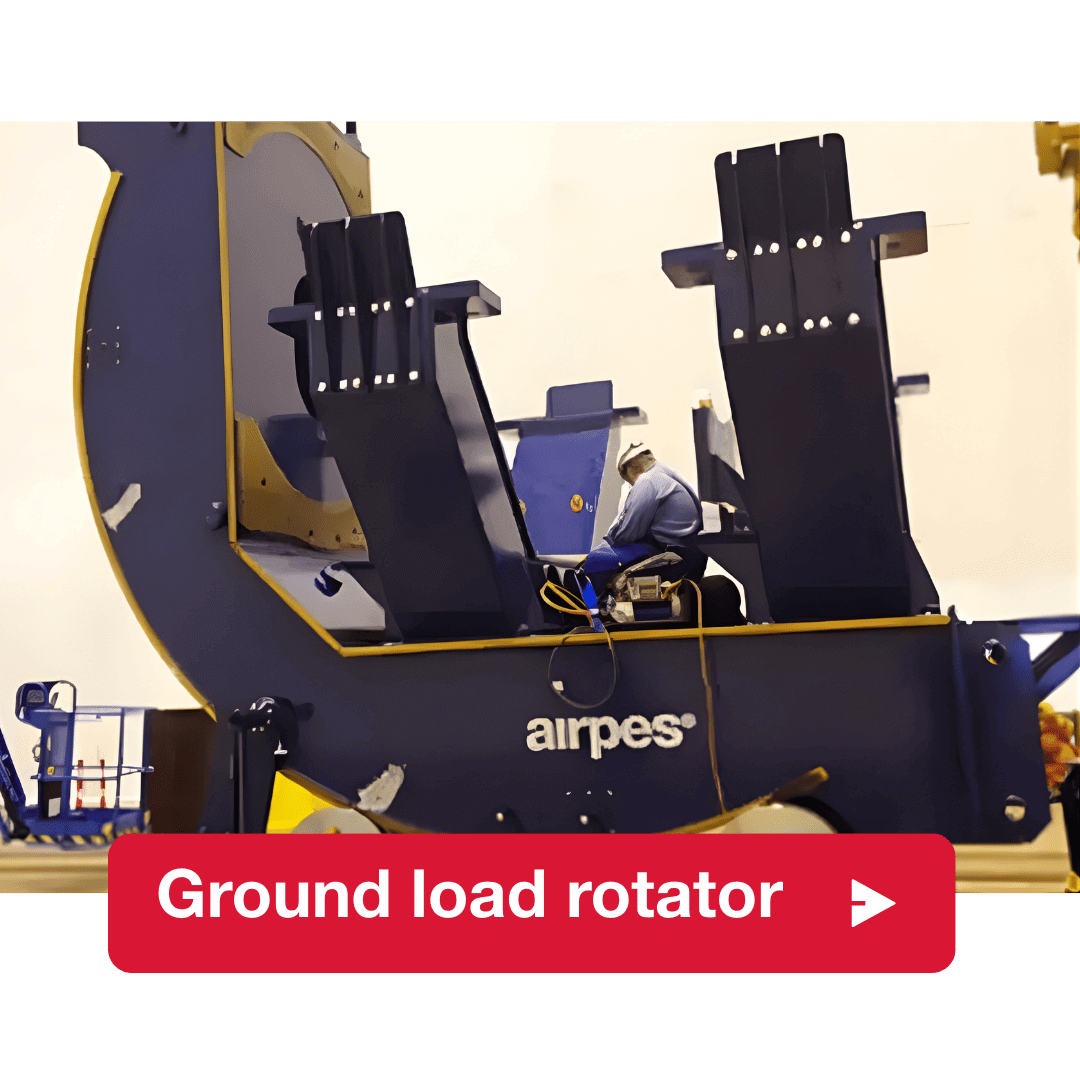

Ground-Based Load Rotators

When the load needs to be tilted or turned at ground level (before or after a lift) ground-based rotators are the right tool. They work independently of a crane and are particularly useful in assembly lines or maintenance workflows where loads need a full 90° or 180° turn.

Tilting & Combined Rotation Systems

Some applications require both tilting and rotation, sequentially or simultaneously. We engineer combined systems that handle multi-axis movement in a single, controlled operation, reducing the number of rigging steps and minimizing exposure time for personnel.

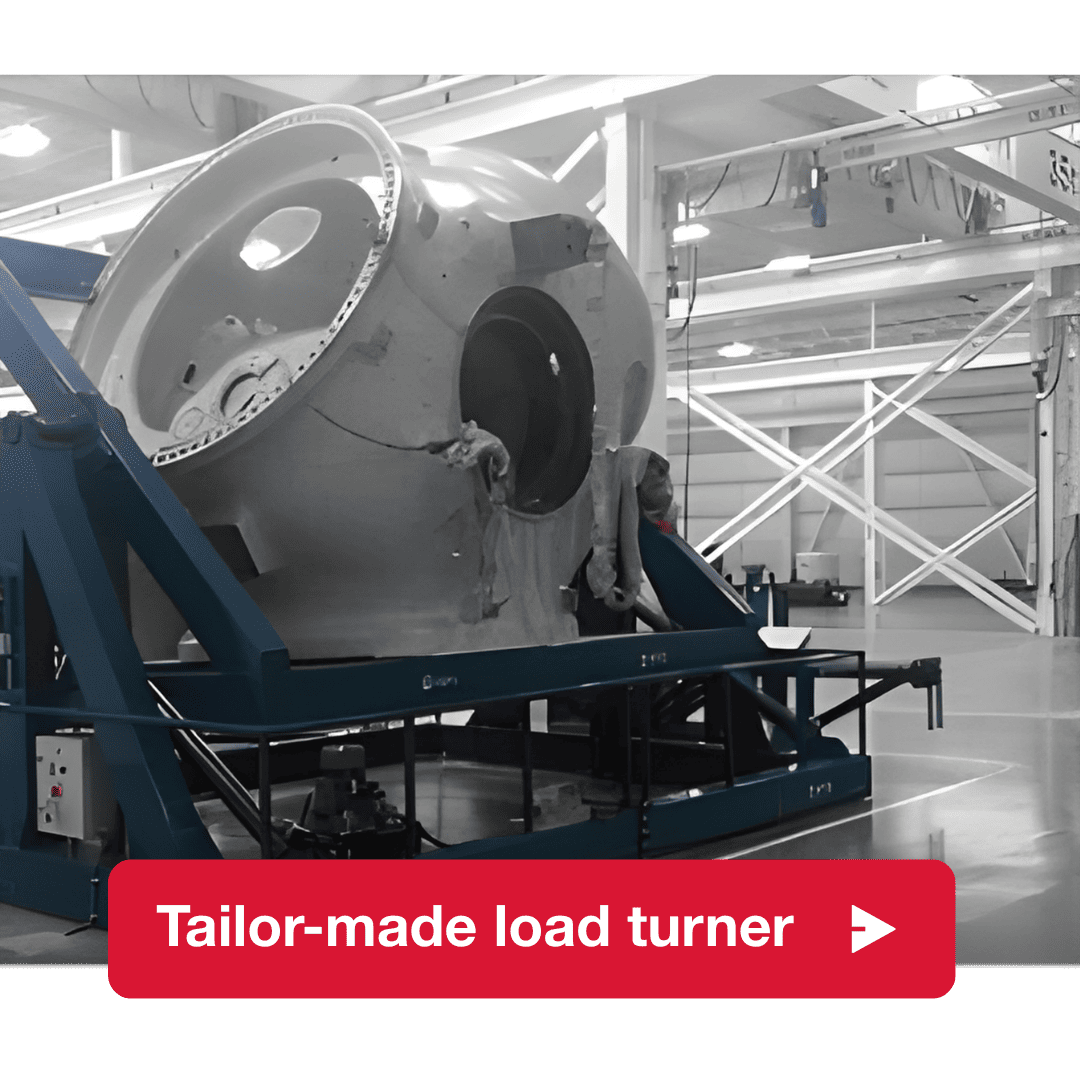

High-Capacity Custom Solutions

When the load exceeds standard capacity ranges, or when the geometry, environment, or process makes off-the-shelf equipment unsuitable, we design fully custom turning devices from scratch. There’s no upper limit defined by a product catalog; the limit is defined by your technical requirements.

You might also find this interesting: How we engineered a custom rotator for the wind sector in Brazil

Key Factors to Consider When Selecting a Heavy Load Turner

Choosing the right heavy load turner isn’t just about matching a weight rating. Here are the factors that actually matter:

Load Capacity and Center of Gravity

The nominal capacity is the starting point, not the finish line. You also need to account for load geometry, the position of the center of gravity, and any dynamic forces generated during rotation. An asymmetric load behaves very differently from a uniform block of the same weight and your equipment needs to be engineered accordingly.

Rotation Range and Speed

Do you need a full 360° continuous rotation, or a controlled 90° tilt? Does the speed need to be variable? Adjustable rotation speed is critical in applications where load stability during movement is a concern; for example, when handling fragile components or working near other structures.

Working Environment

Indoor or outdoor? Fixed installation or mobile? Explosive atmosphere (ATEX)? Elevated temperatures? Each of these variables affects material selection, sealing, drive type, and control systems. A heavy load turner engineered for a shipyard is a fundamentally different product from one designed for a cleanroom environment.

Beginning to learn how to choose heavy duty lifting & handling equipment? This article will help: How to select material handling equipment

Integration with Existing Equipment

The turning device doesn’t work in isolation. It needs to interface with your crane, your production line, your control systems, and your maintenance procedures. We always design with integration in mind (including load monitoring, remote operation, and compatibility with existing rigging hardware).

Safety and Regulatory Compliance

This is non-negotiable. Any industrial load turning device operating in a professional environment must comply with applicable machinery directives and safety standards. We design and manufacture in accordance with ISO 45001:2018, the international standard for occupational health and safety management, which you can review directly from ISO. Our quality management system follows UNE-EN ISO 9001, ensuring that every step of the engineering and manufacturing process is documented, validated, and traceable: you can consult the standard here.

Beyond certifications, we also conduct load testing, fatigue analysis, and risk assessment as standard parts of our delivery process; not optional add-ons.

Explore our fulll range

-

LOAD ROTATOR

Meet our range of high capacity electric powered rotators designed to rotate all types of materials. It can be adapted to…LOAD ROTATORSeptember 22, 2020

Real-World Applications: Where Heavy Load Turners Make the Difference

The industries that come to us most frequently share one thing in common: they handle components that are large, expensive, and structurally sensitive. A handling incident doesn’t just cost money… it can set a project back by weeks.

Wind energy is one of our most active sectors. Nacelles, hubs, and blade root sections require very specific handling sequences, and the consequences of an improper rotation are severe. We’ve delivered custom industrial load turning devices for wind manufacturers and installation contractors across Europe and Latin America.

Oil & gas and petrochemical facilities need rotation solutions for pressure vessels, heat exchangers, and large pipe assemblies — typically in environments with strict ATEX requirements and long maintenance cycles.

Naval and offshore applications involve oversized structural components where ground-based tilting systems allow precise positioning before final assembly or welding.

Heavy manufacturing and fabrication shops use our equipment to turn large weldments and machined parts through multiple process steps without re-rigging — reducing cycle time and improving repeatability. In these environments, having a purpose-built industrial load turner means operators spend less time on rigging and more time on productive work.

In all of these cases, the common thread is that a standard product from a catalog wasn’t the right answer. What worked was a solution engineered specifically for the load, the process, and the environment.

Why Crosby Airpes

We are part of Kito Crosby, one of the world’s leading lifting and rigging organizations, which means our engineering capabilities are backed by global resources, R&D investment, and decades of technical expertise in critical lifting applications.

What we bring to every project:

- Full custom engineering: no standard catalog, no forced compromises

- In-house design and manufacturing (from concept to load test, everything happens under one roof).

- Certified quality and safety processes aligned with international standards.

- Direct technical support: you work with our engineers, not a sales intermediary

Whether you need a compact ground-based tilter or a multi-ton aerial rotation system, we’ll engineer it to fit your exact requirements.

Ready to define your solution?

If you’ve reached this point, you probably have a specific challenge in mind (a load, a process, or an application) where standard equipment just doesn’t cut it.

Let’s talk about it. Our engineering team will review your requirements and come back with a technical proposal tailored to your operation — no generic quotes, no off-the-shelf answers.