What Is a Hoisting Weight Limiter?

A hoisting weight limiter is a specialized device that safeguards lifting operations by preventing hoists and cranes from exceeding safe load thresholds. Unlike generic load limiters, these are engineered specifically for vertical lifting tasks, ensuring the system halts or issues alerts when predefined weight limits are surpassed.

Definition and Core Functionality

This type of limiter continuously monitors the vertical lifting force. When the load approaches or surpasses the preset limit, the system either interrupts the operation or warns the operator. It acts as a real-time safety mechanism, reducing the risk of accidents and equipment strain.

Differences from Other Load Limiters

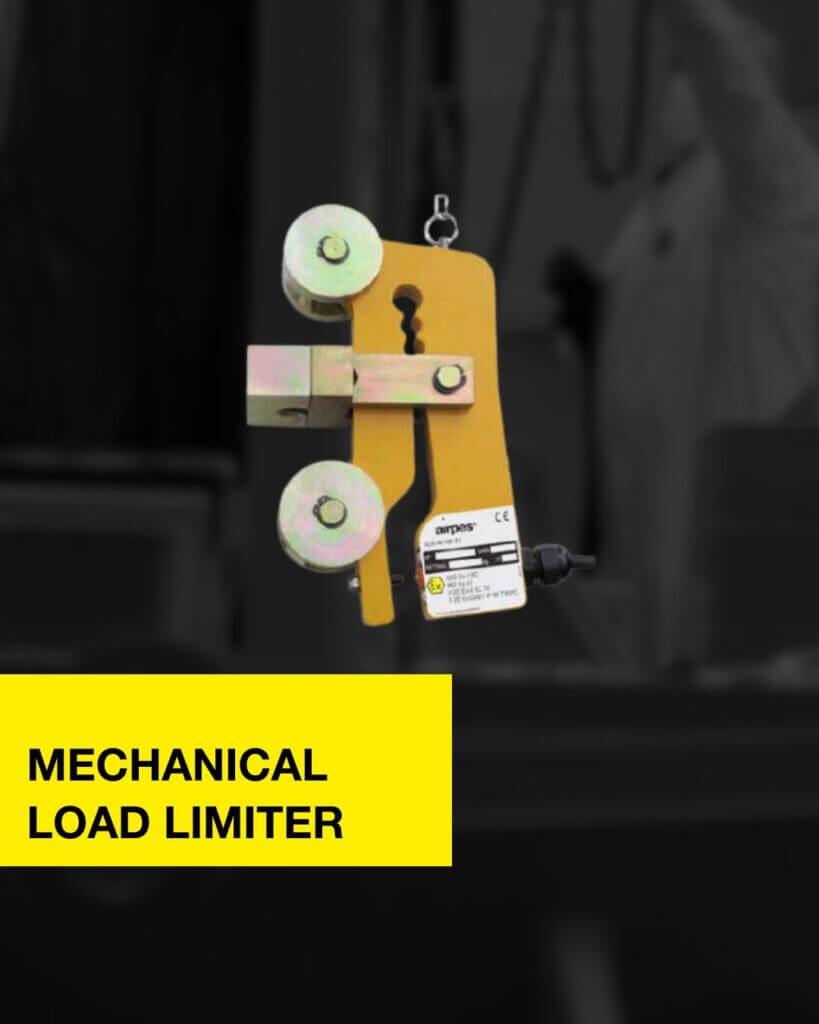

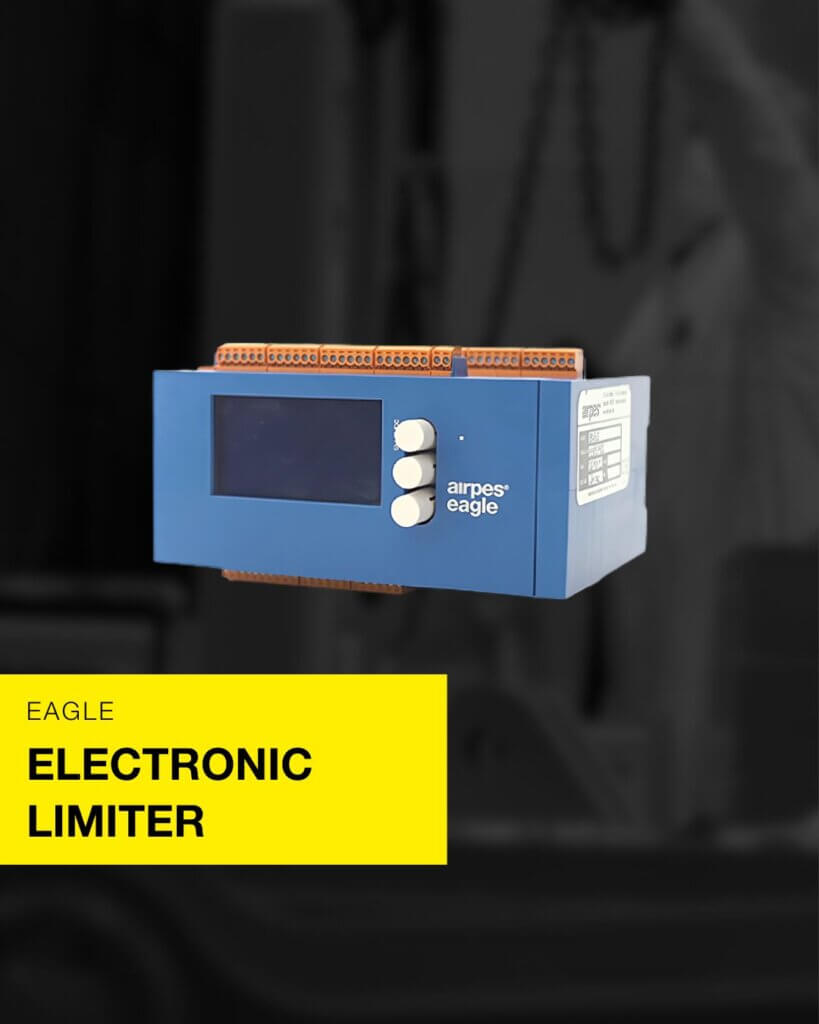

It’s important to distinguish hoisting weight limiters from other types like mechanical overload protection devices, which are widely used in cranes for horizontal force management, or from electronic limiters, which are highly configurable systems like the ALE-100/T model. While these devices offer broader functionalities, hoisting weight limiters are uniquely tailored for vertical load control

| Feature / Limiter Type | Hoisting Weight Limiter | Mechanical Limiter | Electronic Limiter |

| Application Focus | Vertical lifting (hoists, cranes, elevators) | General overload protection (mostly in mechanical cranes) | Broad industrial use (configurable for various systems) |

| Monitoring Method | Real-time load measurement in hoisting motion | Mechanical tension and deformation detection | Digital sensors and PLC feedback |

| Automation Capability | Medium (basic stop or alert system) | Low (relies on physical limit triggering) | High (can integrate with full control systems) |

| Precision Level | High for vertical force accuracy | Moderate, depends on mechanical calibration | Very high, adjustable thresholds and real-time adjustments |

| Maintenance Needs | Low to medium | Low, but requires periodic physical inspection | Medium to high depending on system complexity |

| Integration | Compatible with hoists and cranes | Installed as part of the mechanical lifting system | Integrated with digital/PLC-based systems |

| Use Case Example | Overhead crane in a factory or port | Manual crane with tension spring limiters | Smart lifting system with touchscreen interface |

Why Are Weight Limiters Crucial in Hoisting Applications?

In industries that rely on heavy lifting—construction, logistics, manufacturing—safety and precision are non-negotiable. Hoisting systems operate under strict safety regulations, and overloads can lead to mechanical failure, financial loss, and personal injury.

Preventing Overloads in Vertical Lifting

By integrating hoisting limiters into your lifting equipment, you prevent sudden stops, snapped cables, and structure deformation. While general load limiter solutions address broader needs, hoisting-specific devices offer a focused defense in vertical lifting contexts.

Ensuring Worker and Equipment Safety

Beyond mechanical failure, lifting accidents often pose serious safety risks to operators. These devices also support compliance with international safety standards like those from OSHA 1910.179, which establish clear requirements for overhead and gantry cranes.

Common Use Cases in Hoisting Equipment

These devices are indispensable in any environment where vertical load movement is routine and safety is paramount.

Cranes, Hoists, and Industrial Elevators

From overhead cranes in assembly lines to electric hoists in production facilities, hoisting limiters ensure operational safety by enforcing load boundaries. For use cases requiring specific maximum load capacity, these systems work in tandem with existing monitoring solutions to deliver precise, layered control.

Heavy-Duty Lifting in Ports and Manufacturing

In ports and shipyards, where cranes handle containers 24/7, or in steel plants, where molten materials are moved at height, hoisting weight limiters drastically reduce operational risk and downtime.

Key Features to Look for in a Hoisting Limiter

Accuracy, Certifications, and Real-Time Monitoring

Top-tier hoisting limiters offer high-precision sensors, certifications like CE and ASME, and integration into real-time monitoring systems. These features ensure reliability and support for regulatory compliance.

Compatibility with Mechanical and Electronic Systems

Whether you’re running legacy equipment or modern setups with digital controls, look for limiters that are fully compatible with both mechanical and electronic safety systems. They often complement or expand upon the features found in mechanical limiters and electronic limiters.

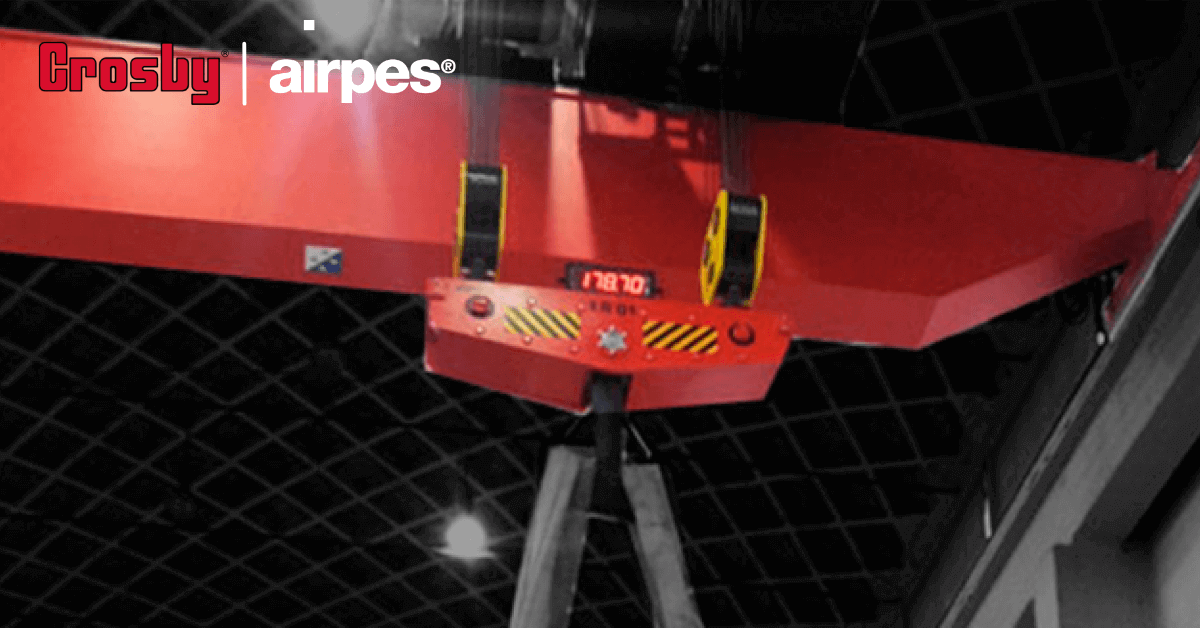

Why Choose Crosby Airpes for Hoisting Safety Solutions?

Crosby Airpes stands out in the lifting industry with decades of engineering excellence, offering tailored solutions that blend cutting-edge safety features with real-world industrial performance.

From load limiter technologies to intelligent control systems, the brand combines innovation with reliability, delivering equipment that is trusted across aerospace, automotive, steel, energy, and logistics sectors.

Optimizing Your Lifting Operations Starts with Safety

Incorporating a hoisting weight limiter into your lifting systems is more than regulatory compliance—it’s a proactive investment in operational integrity and workplace safety. These devices not only prevent overload accidents but also extend the life of your equipment and boost productivity. Whether you’re outfitting a new crane or upgrading an existing system, Crosby Airpes offers tailored hoisting safety solutions ready to meet your industry’s unique demands.