When it comes to moving heavy loads efficiently, a gantry crane —also known as a portal crane— is one of the most versatile lifting solutions. Unlike bridge cranes, gantries are supported on legs that run on rails at floor level, making them highly adaptable to indoor and outdoor operations.

In Crosby Airpes, we are experts in designing the best equipment so your gantry crane can effectuate many different operations. If you are already using gantry cranes, or considering investing in one, this guide will help you understand their types, applications, design considerations, and how you can maximize performance with the right lifting solutions.

What is a gantry crane?

The gantry crane is a variant of a crane placed on a gantry structure or similar, with the whole system designed to straddle above a space carrying the load or the object that needs to be moved. Gantry cranes are also called portal cranes, the “portal” being the space straddled by the gantry.

A gantry crane has many similarities to an overhead crane. The main difference between a gantry crane or portal crane and an overhead crane is that the gantry crane has a girder and legs that move on a rail, while in an overhead crane, the beam rests directly on rails. Overhead cranes (or bridge cranes) are attached to the interior structure of a building and are a permanent installation in factories and warehouses.

Gantry cranes are more flexible and versatile than bridge cranes. They can be moved where required.

You may be interested in: 6 overhead crane safety tips to protect your workers

Types of Gantry Cranes

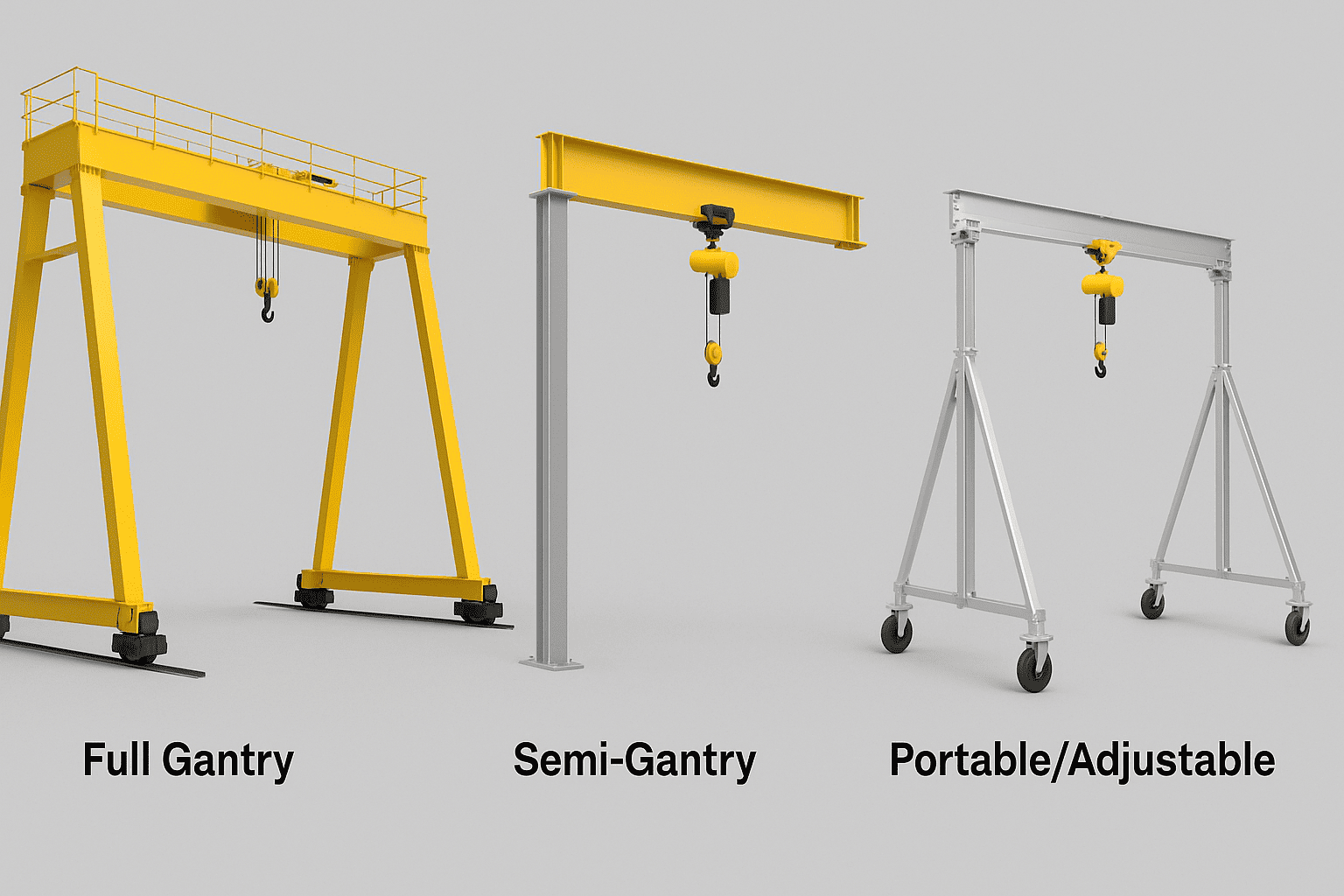

There isn’t a one-size-fits-all. Depending on your space, budget and operational needs, you might find these variations:

- Full Gantry: Two legs running on ground rails, spanning across the working area. Best for yards and ports.

- Semi-Gantry: One leg runs on the floor, the other supported by a building structure. Perfect for spaces with limited width.

- Portable Gantry: Mobile, lightweight frames (often aluminum) that can be moved between work areas. Ideal for workshops and maintenance.

- Adjustable Gantry: Height- or span-adjustable models that adapt to different loads and spaces.

Tip: Always analyze your duty cycle (frequency and type of load) before choosing. A portable gantry may work for light, occasional lifting, while a full gantry is built for 24/7 operations.

Operations you can do with a gantry crane

Moving loads

The biggest existing gantry cranes are those used for moving heavy loads, especially for loading and unloading containers from boats on decks and harbors. As well, there are some big gantry cranes used for the construction of boats, cruise ships, and oil rigs, capable of moving tenths of thousands of tons. In fact, the biggest cranes in the world are gantry cranes: simple but effective design.

Weighing loads

With a slight adaptation of the crane, you can use it to weigh heavy loads precisely. No need to use a loaded lorry on an industrial scale to know how many tons of material you are transporting or moving. With a high-precision scale for big weights, your gantry crane will allow you to weigh while moving the material inside your production plant. That’s efficiency taken to the limits.

Please take a look at our weighing solutions. We can adapt them to your gantry crane.

Rotating loads

Turning heavy loads without damaging them or causing damage to goods, people or infrastructures is a very critical operation. It doesn’t matter if it is a concrete structure, the keel of a boat, or any intermediate product that needs to be rotated to carry out more operations. A few tons fall on the floor because of a lousy load turning device translates into a substantial economic and material loss and probably damages goods and infrastructure. With the adequate hoist and mechanism, Crosby Airpes can adapt your gantry crane for rotating any object. It doesn’t matter the size, volume, and weight.

You may be interested in: On-demand rotator for a Brazilian Wind Turbine Towers Manufacturer

Design & Electrification Considerations

Before choosing or upgrading your gantry system, keep these design points in mind:

- Power delivery: Ensure proper cable reels or busbars to avoid sagging cables.

- Indoor vs. outdoor: Outdoor gantries need galvanization, protective panels, and heaters for motors.

- Traffic management: Place panels and gearboxes strategically to avoid collision risks.

- Duty class & speed: Gantries are not designed for high-speed lifting — choose wisely to avoid wear.

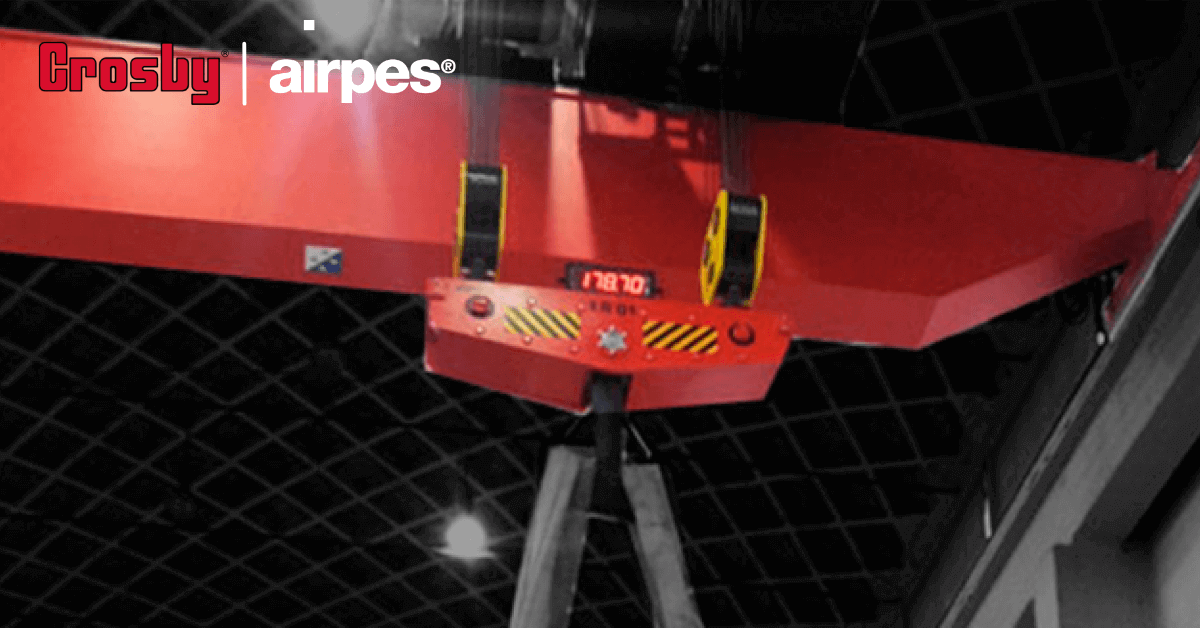

Pro tip: Ask your supplier if your gantry crane can integrate electronic limiters and monitoring displays. At Crosby Airpes, we specialize in designing and integrating these add-ons to enhance safety and control in your lifting operations.

Industries & Applications

Gantry cranes are widely used across multiple industries due to their versatility and adaptability to different environments. Here are some of the most common applications:

-

Ports and container yards: Ideal for loading and unloading shipping containers or bulk cargo. Their free-standing legs and wide spans make them essential in maritime logistics. Adding spreader beams or lifting frames ensures faster and safer container handling.

-

Steel and scrap yards: Frequently used to move coils, steel plates, or large beams. In these environments, operators often integrate C-hooks, magnets, or heavy-duty tongs to grip and transport irregular shapes efficiently.

-

Precast and cement industry: Gantry cranes are key in handling concrete panels, precast beams, and other oversized elements. With the addition of load rotators, precast elements can be turned safely for inspection, finishing, or installation.

-

Rail yards: Employed for maintenance and cargo transfers, especially for rails, wheels, or heavy components. Weighing systems and load cells are commonly integrated here to verify load weight during handling.

-

Workshops and service facilities: Smaller portable or adjustable gantries allow technicians to lift engines, machinery, or tools within confined spaces. Their mobility makes them especially useful for repair and assembly tasks.

In every case, the crane itself provides the structure, but efficiency, safety, and productivity depend on what you attach below the hook. With the right accessories—whether spreader beams, weighing hooks, or monitoring limiters—you transform a standard gantry into a tailored lifting solution that delivers consistent results.

Compatible Below-the-Hook Solutions: our Edge

Crosby Airpes is your best lifting supplier when it comes to enhancing gantry crane operations:

- Spreader beams & lifting beams: For bulky or long loads.

- C-hooks & tongs: For coils, pipes and irregular pieces.

- Lifting magnets: For steel plates and scrap handling.

- Load rotators: For safe turning of heavy components.

- Weighing systems & load cells: For integrated, precise load control.

- Electronic and mechanical limiters: To prevent overloads and accidents.

All engineered on demand, adapted to your gantry’s specs.

How to Choose the Right Gantry Crane (Checklist)

Before investing in a gantry crane, it’s important to evaluate a few key factors:

-

The capacity you need in tons.

-

The span and lifting height required for your operations.

-

Whether the crane will work in an indoor or outdoor environment.

-

The type of power supply and electrification system available.

-

The duty class (light, medium or heavy service).

-

Any accessories needed, such as weighing systems, rotators or magnets.

-

The right safety devices, including limiters and monitoring displays.

FAQs about Gantry Cranes

1. What is the difference between a gantry crane and an overhead crane?

A gantry crane is a freestanding structure supported by legs that move on rails or wheels at floor level, while an overhead (bridge) crane is fixed to the building’s structure and runs on elevated runways. Gantries are more flexible, portable, and often used outdoors, whereas overhead cranes are permanent indoor solutions.

2. What are the safety rules for gantry cranes?

Key safety rules include:

- Never exceed the rated load capacity.

- Inspect hooks, ropes, and limiters before use.

- Avoid side pulling or sudden movements.

- Keep operators clear of suspended loads.

- Use electronic limiters and monitoring displays to prevent overloads.

3. When would you use a gantry crane?

You use a gantry crane when:

- The building lacks overhead runway structures.

- You need outdoor lifting (yards, ports, construction).

- Flexibility is required (portable or adjustable gantries).

- The project is temporary or the crane must be relocated.

4. How does a gantry crane work?

A gantry crane works by moving loads along a horizontal beam (girder) supported on vertical legs. A trolley with a hoist travels along the girder, raising or lowering loads via a hook or specialized below-the-hook device. The entire gantry can move on wheels or ground rails, providing full mobility.

5. Can you move a gantry crane while loaded?

Portable gantry cranes with wheels can sometimes be moved under light load, but full and semi-gantry cranes should never be relocated while loaded due to stability risks. Safety standards generally prohibit moving heavy gantries with suspended loads to prevent tipping or structural stress.

6. What are the disadvantages of using a gantry crane?

- Speed limitations compared to overhead cranes.

- Space requirements for rails or ground clearance.

- Weather exposure if used outdoors without proper protection.

- Load limits in portable/adjustable models (lighter duty).

7. What powers a gantry crane?

A gantry crane can be powered in different ways depending on its size and design:

- Electric motors: the most common solution, used for both hoisting and crane travel.

- Hydraulic systems: found in specialized heavy-duty gantries that require high lifting force.

- Manual operation: limited to small portable gantries for light loads.

For large industrial gantries, power is usually supplied through electrification systems such as cable reels, festoon systems, or conductor bars, ensuring continuous and safe energy delivery.

8. How much can a gantry crane lift?

Capacities vary widely:

- Portable gantries: up to 5 tons.

- Semi/adjustable gantries: 10–50 tons.

- Full gantry cranes: custom-engineered to exceed 300 tons.

9. What is the lifespan of a gantry crane?

A well-maintained gantry crane typically lasts 20 to 30 years, depending on duty class, environment, and frequency of use. Regular inspections, preventive maintenance, and integration of monitoring systems extend service life.

10. How many legs does a gantry crane have?

Most gantry cranes have two legs supporting the main girder.

- Full gantry: two legs on rails.

- Semi-gantry: one leg + building structure.

- Portable/adjustable: two lightweight legs with wheels.

The perfect lifting and handling solutions for your gantry crane

A gantry crane is just the beginning. What really drives performance is what hangs below the hook. With us, you can upgrade your gantry with tailor-made solutions for weighing, rotating, gripping, or protecting your operations.

Whether you manage a steel yard, a precast plant, or a container terminal, we’ll help you transform your gantry crane into a smart lifting system.

Ready to get more out of your gantry crane?

Contact us today to design the right below-the-hook solution for your project. Let’s build the lifting system that saves time, improves safety, and maximizes ROI.

We also can transform your gantry crane on a high-capacity industrial scale or adapt it to a high-capacity loads rotator.