Monitoring and overloading protection systems could be an impossible mission without load cells. You also need to know what type of load cell is essential to perform your job correctly.

If you have arrived at this post, you are looking for the perfect complement to your industry. And we will find it for you.

LIFTING 1.1 How load cells work

If you are an expert in handling and lifting equipment, skip this part and continue reading below. Apprentices… ¡welcome!

A protection system in an industrial setting refers to a comprehensive set of measures, devices, and protocols designed to ensure the safety of the workforce, the protection of equipment and facilities, and the mitigation of risks associated with industrial processes. These systems are critical in maintaining safe operational conditions, preventing accidents, and ensuring compliance with safety regulations. At these protection systems we include the cells.

A load cell is a device that turns pressure into an electric signal. It’s a part of scales used in businesses and industries to weigh things and is also used by scientists and testers.

Here’s how it works: inside the cell is a small part called a strain gauge. The strain gauge gets squished or stretched when you push down on the cell. This squishing or stretching changes how much electricity can flow through it. More force is applied, which means more change. This change is measured with special electronics (force sensors) and turned into an output signal, a number that tells you how much force or weight is being applied.

Precision wighing, process control, safety, cost savings, regulatory compliance, quality assurance, inventory management…Why don’t you have a load cell if you have any of these needs?

At Crosby Airpes, we design and supply cell converters that accurately read and measure the electrical analog signal. These devices transform the electrical signals into a digital weight value and transmit the data using CANopen, a sophisticated communication protocol and software commonly used in industrial settings.

Many businesses opt for these cells because they are cost-effective and don’t require complex wiring for installation.

If you want to prove new technologies, check our load cell solutions for every industry, company, or need.

What types of load cells do I need to improve my work?

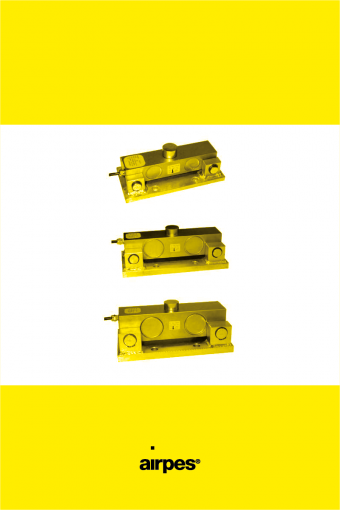

There are different types of cells based on their shape, size, and the way they detect weight, including compression cells, bending beam load cells, and shear beam load cells, among others. Each type has its advantages and specific applications where it performs best.

When you are applying too much force, compression load cells

Indicates when the compression force is applied. For example, in building projects, cranes use powerful pumps to squeeze fluids in cylinders to pick up heavy items and move them where they need to go. In industries that lift and tie heavy loads, squeezing forces happen when piling things up, using powerful lifting tools like hydraulic jacks, or when heavy items are held up by pillars or big horizontal bars.

The compression cells by Crosby Airpes are designed to work in compression with a shear or double shear sensor.

-

COMPRESSION LOAD CELLS BP

The compression load cells BP are specially designed to work with compression with element detecting a shear or double shear.…COMPRESSION LOAD CELLS BPSeptember 22, 2020

-

DC COMPRESSION LOAD CELLS DCO-2, DCO-3, DCO-4

The DCO-2, DCO-3 and DCO-4 models of load cells have been specially designed to work with compression in double shear.DC COMPRESSION LOAD CELLS DCO-2, DCO-3, DCO-4November 11, 2020

-

LOAD CELLS COMPRESSION AC-A

The model AC-A load cells have been specially designed to work under compression in column.LOAD CELLS COMPRESSION AC-ANovember 11, 2020

-

LOAD CELLS COMPRESSION SKP

Load Cells compression SKP especially designed for the control of the charge in silos.LOAD CELLS COMPRESSION SKPNovember 11, 2020

-

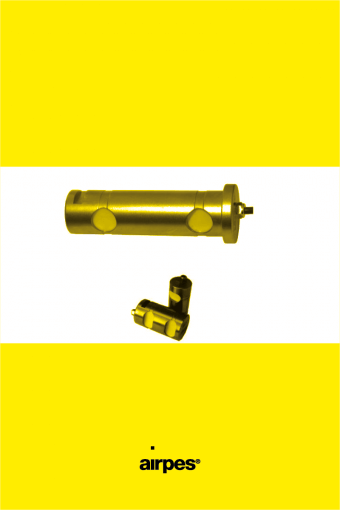

SPRING PIN LOAD CELL BL

The BL model of load cells have been specially designed to work with traction or compression with element detecting a…SPRING PIN LOAD CELL BLNovember 11, 2020

-

LOAD CELLS COMPRESSION SKM

Cells especially designed and manufactured for the control of the charge in silos. Includes an anti –capsizing support Features Load…LOAD CELLS COMPRESSION SKMSeptember 22, 2020

Perhaps, if you need to monitor mixing machines or tanks, you will be interested in “Load cell for mixing tanks.”

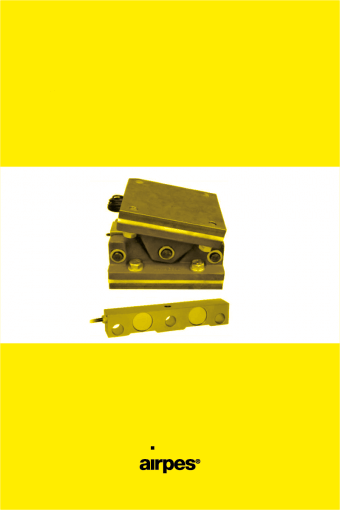

When you need elasticity, flexion load cells

These tools are specifically engineered to measure shear. We can be talking about shear beam (to measure forces with a piece of metal that is elastically deformed under load and recovers when load is removed). Also, bending beam convert a force applied to it into an electrical signal by measuring the flexure of the beam. Bending beams are for lighter, more precise tasks, while shear rays are for more challenging, heavier jobs.

https://www.airpes.com/product/flexion-load-cells-cf-and-cfa/

https://www.airpes.com/product/flexion-load-cells-fx1-fx2/

More & more

Traction. Their primary use is in applications where force is applied by pulling apart rather than compression. For example, TRACTION CELLS CT.

Converter. When you need to convert the signal into a weight value, transmit alerts for underweight, overload, out-of-range conditions, and cable breakage—for example, CELL CONVERTER ACO-200.

Limiter. To measure the load in steel cables. For example, LIMITER CELLS LM.

You may be interested in: 10 safety precautions when using lifting equipment

Crosby Airpes provides you with the material handling equipment you need

At Crosby Airpes, we help you find the load cell that best suits you to work safely.