As the global wind energy sector continues to expand, the demand for specialized lifting equipment that ensures safe and efficient wind turbine engineering; installation and maintenance has never been higher. Crosby Airpes, part of the Kito Crosby Corporation, has established itself as an industry leader among companies that install wind turbines with its fully in-house designed and manufactured Wind Turbine installation and services tools that are revolutionizing component’s handling operations worldwide.

Innovative Design Delivers Unmatched Safety and Reliability

Our involvement spans the entire value chain—from the mechanical and electronic design of custom lifting and handling systems to the full deployment of turbines in complex environments. By owning both the engineering and operational phases, we eliminate system interface issues, reduce lead times, and maintain end-to-end control over performance and safety parameters.

Complete In-House Engineering: The Crosby Airpes Advantage

What distinguishes us apart from competitors is the comprehensive in-house design and manufacturing approach.

Unlike other wind turbine installation suppliers who typically source from external suppliers part of the equipment, like electronic components, remote controllers, and other critical elements, Crosby Airpes develops and produces every component under one roof.

We design, produce, test, and use our own lifting and handling systems in every installation project we lead. This model eliminates friction, ensures seamless compatibility between systems, and boosts safety performance across all operations.

Our teams are made up of experienced engineers and field technicians who understand the mechanical, electrical, and aerodynamic intricacies of modern wind turbines. Whether it’s a land-based installation or a challenging offshore project, our solutions are built—and applied—with precision.

“This integrated approach eliminates interface issues, resulting in a safer, more reliable, and easier to use equipment”. The seamless integration of all systems ensures consistent performance even in the most challenging installation environments.

How We Stand Out Among Companies that Install Wind Turbines

Innovative Blade Clamp and Tilting System

What sets us apart in the field of wind turbine engineering is that our lifting and handling systems are not only developed for external deployment: they are engineered for operational use in our own installation projects. This hands-on application ensures that our solutions are not theoretical prototypes, but field-proven technologies refined through direct use in high-precision assembly environments—both onshore and offshore—by companies that install wind turbines, including our own teams.

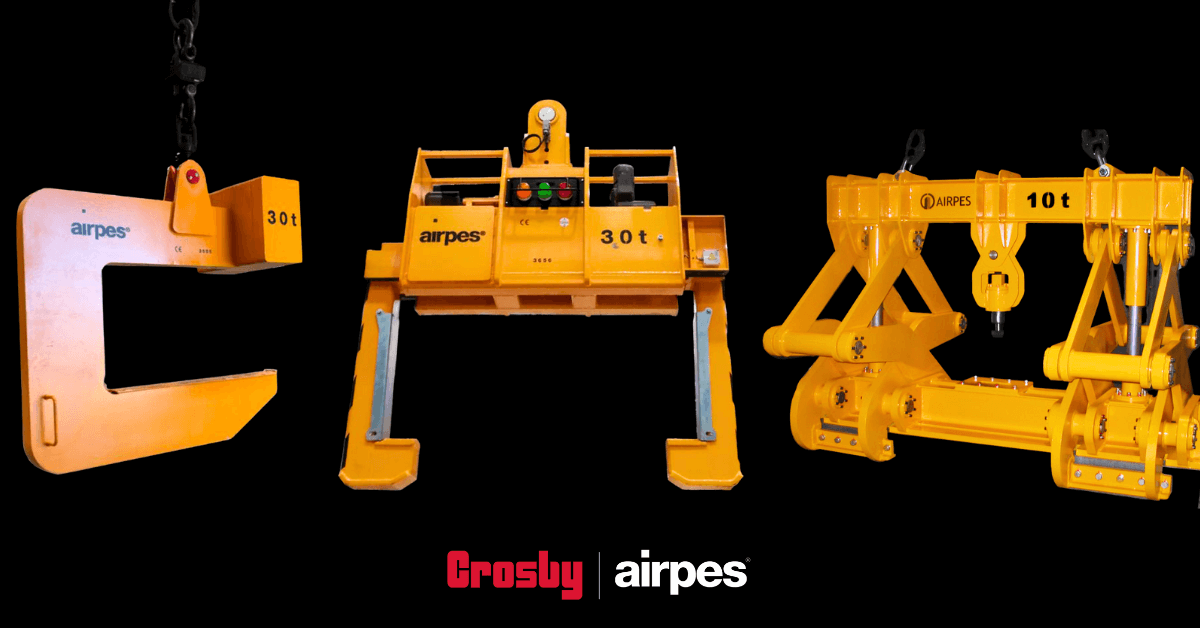

The company’s flagship product, the Wind Turbine Blade Clamp, addresses one of the most critical challenges in turbine installation and maintenance: safely handling massive blades. The modular and adaptable design allows the clamp to be quickly set to work effectively with multiple blade geometries from different manufacturers, providing versatility that reduces equipment needs and operational costs.

Complementing the Blade Clamp our innovative Tilting system, a specialized tool designed primarily for service operations. Removing an installed blade is much more complex than installing a new one. The Tilting system can compensate blade CG variations (e.g. due to damages), by adjusting the angle to maintain a horizontal blade position, enabling safer execution of those maintenance operations.

Global Track Record of Excellence

With more than 400 blade clamps currently in operation worldwide, Crosby Airpes has built an impressive track record serving major wind turbine contractors. This extensive field experience has allowed continuous refinement of their designs based on real-world performance data.

Our track record includes:

- Multi-megawatt turbine installations across Europe and North America

- Specialized offshore campaigns requiring tight weather windows and dynamic positioning

- Onshore farms in mountainous regions with difficult crane access

- Maintenance and repowering operations for aging turbines

Through each of these projects, we’ve refined our approach based on real-world conditions, feedback from field teams, and evolving industry standards. This feedback loop allows us to constantly improve our processes and technologies.

Quality Standards That Define Top Wind Turbine Engineering

The company’s commitment to quality is further demonstrated by its comprehensive certifications, including ISO 9001 (quality management), ISO 14001 (environmental management), ISO 45001 (occupational health and safety), and ISO 3834-2 (fusion welding quality requirements).

Additionally, Crosby Airpes manufactures under APQP4Wind recommendations, adhering to the wind industry’s most stringent quality standards.

Engineering Excellence for the Renewable Energy Future

Wind turbines are getting bigger, heavier, and more complex. Installation requirements are no longer just logistical, they are deeply engineering-driven.

As a result, wind turbine engineering partners must evolve and become full-system integrators, supporting the growing needs of renewable energy. Crosby Airpes is leading that shift.

For wind turbine manufacturers seeking lifting equipment that combines cutting-edge engineering with proven field performance, Crosby Airpes offers a compelling package of technical expertise, quality assurance, and industry-specific experience that few competitors can match.

Learn more about our fully engineered lifting and handling systems on our On-Demand Solutions page, where all equipment is tailored to real operational requirements.

Why choose Crosby Airpes for your wind turbine engineering project?

- We engineer and test the tools we use

- We minimize third-party dependencies

- We handle the entire installation process

- We meet the highest safety standards

- We have a proven global track record

Whether you’re a developer, OEM, or EPC contractor, working with Crosby Airpes means reducing risk, increasing operational control, and ensuring the highest standards from start to finish.

Let’s build the future of wind energy together

You need a partner who understands the big picture and the smallest detail. As one of the few vertically integrated companies that install wind turbines, Crosby Airpes is ready to meet your technical and business goals with precision and top-notch wind turbine engineering.

Ready to talk? Reach out to discuss your next project.