Safety is a must when we design our equipment. We need to consider every aspect that can affect the lifting process to guarantee the well-being of the technicians that will use our products. One of these elements is the factor of safety (FOS) or safety factor.

Discover the essentials about the safety factor of lifting devices and what their function is.

What is the safety factor in lifting equipment?

The safety factor or factor of safety (FOS) creates a margin for uncertainties in case of unexpected excess forces or malfunction. We calculated this characteristic by the structural strength divided by the minimum structural strength required. The greater the safety factor, the lower the likelihood of structural damage is and the more stress cycles the structure can take.

Therefore, the safety factor serves to determine the maximum load that lifting equipment can withstand safety when in use and ensures safe operations.

The factor of safety is represented as a ratio. For example, if your equipment needs to lift 2,000 kg, and its safety factor is 4:1, the equipment will be designed up to 8,000 kg.

The factor of safety depends on the materials and the use of equipment.

The factor of safety in lifting equipment design

When designing any lifting solution, we need to calculate the forces we apply to the equipment to establish safety limits.

Around the world, legal requirements for safety factors for lifting equipment put on the market vary. Some examples:

- In the US and the EU, it has to be between 4:1 and 7:1 for rigging equipment and between 2:1 and 3:1 for hoisting devices.

When designing lifting equipment, the safety factor of the equipment can be calculated mathematically or tested a lot until it fails several times so that the manufacturer can determine the load it is likely to break. This data establishes the maximum load that a piece of equipment can safely withstand.

You may be interested in: The importance of crane deflection limits in the design of lifting devices

Other safety options for lifting equipment

In addition to designs developed with all the safety guarantees, Crosby Airpes offers you a wide range of Monitoring and Overload Protection Systems.

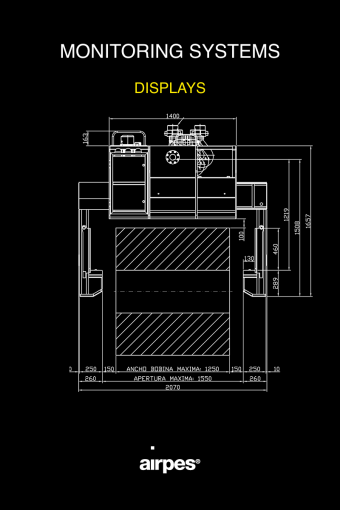

Displays

The display controls the scales and gives us information, becoming an essential element in any operation. Depending on the type of machinery, you can need a specific display or a display with unique features. We can adapt them to the needs of each situation. Discover the benefits of our macro displays.

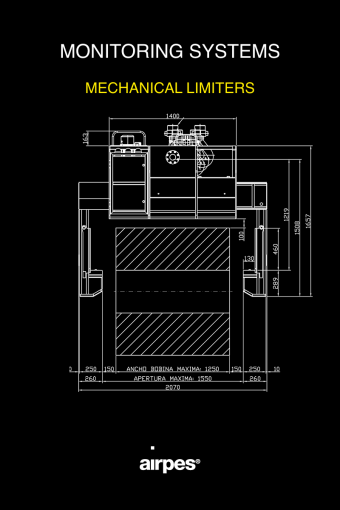

Mechanical Limiters

Mechanical load limiters control and protect overloading machines under operation, avoiding possible problems or accidents. Mechanical load limiters are connected to the crane via the hoist.

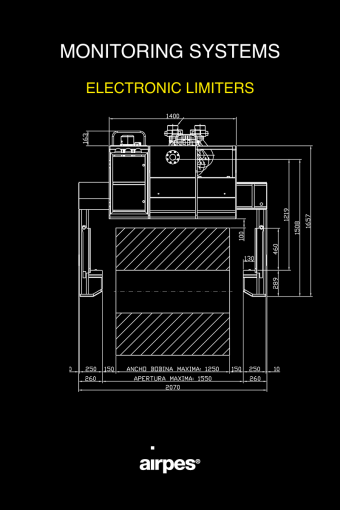

Electronic Limiters

Electronic limiters have a lot of benefits. Electronic limiters control the load and also record data concerning the various lifting and weighing systems of the elevation process, unlike mechanical limiters.

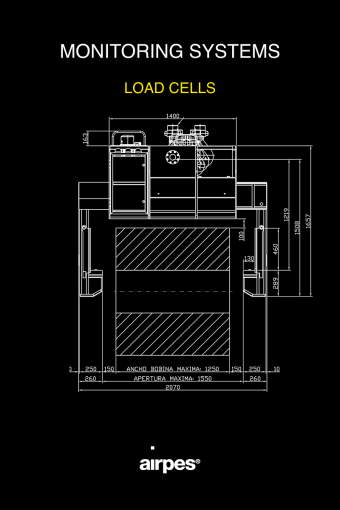

Load Cells

Load cells are high-precision sensors that capture and measure data for safety, measuring service calibration and automation. Load cells also help on technical fatigue, machinery testing, and test benches.

Crosby Airpes manufactures the lifting equipment you need safely and securely

Crosby Airpes designs and manufactures safe lifting equipment that fulfills all your needs.