What do we study and calculate when designing a lifting magnet?

Designing lifting magnets means having to take into consideration many variables. Our engineers put many variables into the calculator for designing an effective lifting device that works through magnetization. The power of the magnet and the crane’s lifting capacity are only two of them.

In this article, we will try to describe some of these variables for understanding how they work.

Does electricity interact with magnetism? Yes it does

Hans Christian Ørsted was a Danish physicist and chemist who discovered that electric currents create magnetic fields, the first connection between electricity and magnetism.

In 1820 Øersted experimented: he placed a long cable in a horizontal and parallel position just above the magnetic needle of a compass. Both the compass and the cable followed exactly the magnetic north-south direction of the Earth. When Øersted connected the ends of the cable to the terminals of a battery, the needle rotated until it adopted an east-west orientation, almost perpendicular to the cable.

Ørsted verified that a resting current does not affect a magnet, but here was the proof that moving charges (an electric current) exert a force on a magnet.

The two types of lifting magnets

Now we know Ørsted’s experiment and proof that electricity affects magnets. It’s time for us to describe how electricity works with magnets. And for this part, we need to know the two different types of magnets we have and how electricity affects them.

Type #1: Lifting electromagnet

An electromagnet consists of a coil of wire wrapped around an iron core. A core of ferromagnetic material like iron increases the magnetic field created. The strength of the magnetic field generated is proportional to the amount of current through the winding and the number of windings.

We apply electricity to an electromagnet to create a magnetic field and lift the load.

Factors to calculate the lifting capacity of an electromagnet

The magnetic field strength of an electromagnet depends on various variables like:

- The core material

- The number of solenoid windings

- The intensity of the current

The electromagnet can develop a magnetic field much more intense than a permanent magnet if the current is powerful enough.

Type #2: Lifting electropermanent magnet

On the other hand, permanent magnets provide magnetic flux, which flows from their North pole to their South pole. So in an electro-permanent magnet, the energy from the permanent magnets keeps the load clamped for an infinite period.

We apply electricity to a permanent magnet to cancel the magnetic field and release the load.

Factors that decrease the lifting capacity of the magnet

The working environment of every company in the world is changing and rarely perfect. Many factors can affect and decrease lifting values. Some of these factors are:

- Air gap caused by dust, coatings in the material, or worn magnet face

- Vibration during transportation of the load that may need extra power

- Extreme temperatures inside the working area or extreme differences of the temperature in the material (materials lose magnetization capacity when the temperature rises)

- Percentage of carbon of the material to be lifted (more carbon in the metal means less magnetization for that piece of metal)

Complete study before the design

Before processing any order of lifting magnets, we try to obtain all the information on the customer’s lifting operations, factors in all conditions, and provide recommendations with the highest safety factor. In the vast majority of the cases, our customers need to lift a wide range of steel materials, so we study all the cases to design the best lifting magnet for that case.

You may be interested in: Lifting tongs design

Experts in lifting magnets design

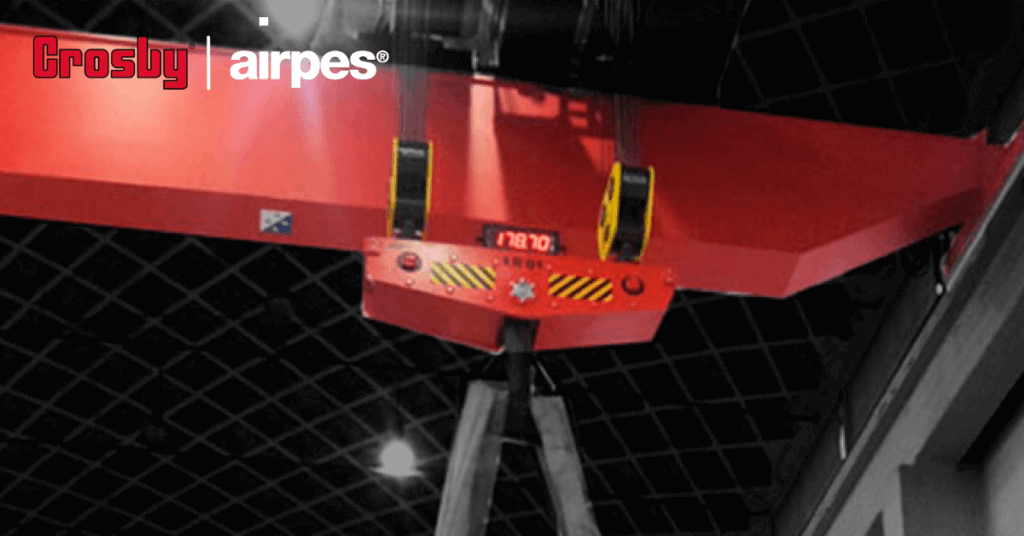

The lifting magnet in the video below has been working in a high-service factor plant since 2012:

Experts in lifting magnets

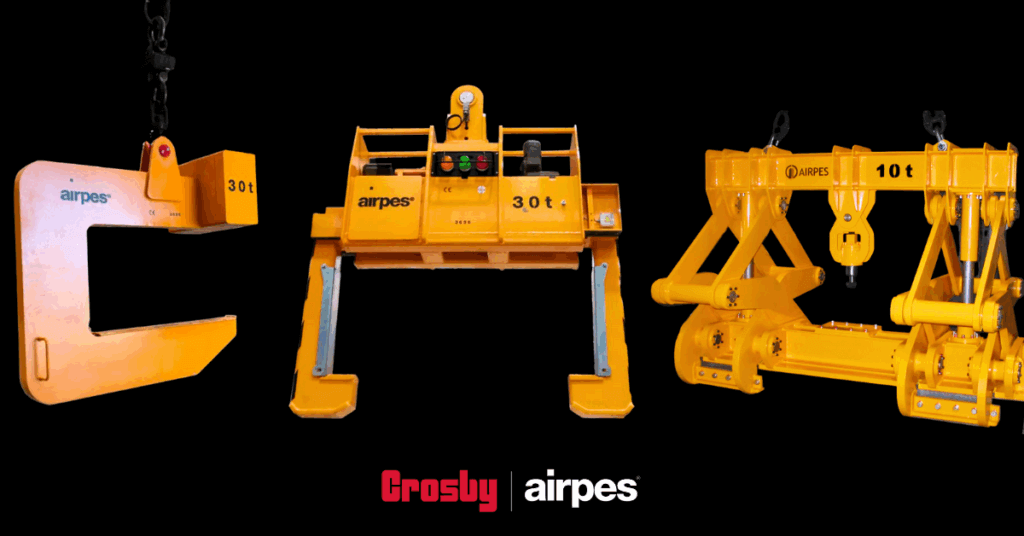

Check some of the projects of lifting magnets we have installed all over the world: