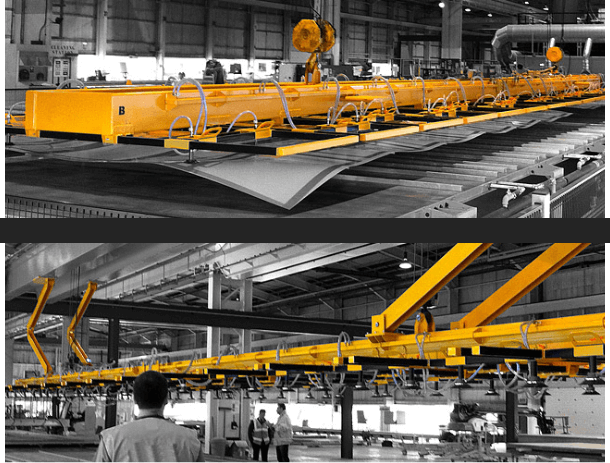

Sheet Lifters for Safe and Efficient Steel Plate Handling

At Crosby Airpes, we design and manufacture sheet lifters that guarantee safe, efficient, and precise handling of steel plates and sheet metal. Our solutions ensure fast leg adjustment and allow additional side force application to secure any load.

Each sheet lifter can be easily adapted to existing cranes or hooks, offering versatile handling for materials of any size, length, or weight.

Improve your material handling operations with Crosby Airpes’ customized lifting solutions.

Features of our sheet lifters

Our sheet lifters are built for heavy-duty tasks, combining robustness with flexibility. Designed as on-demand solutions, each unit is tailored to your company’s needs, enhancing productivity and ensuring safe, precise handling.

Sheet lifter’s features

These are the features of the Airpes’ sheet lifter:

- Hydraulic heavy duty system for reliable performance

- Electro mechanic part (including PLC to assure good use and avoid damages)

- Integrated lighting system for improved visibility

- The product can be protected by extra plastic pads and supplies to reduce damage.

- Customizable dimensions, capacity, and control features based on your crane’s specs and operational needs.

Optional upgrades for enhanced functionality

You can improve our sheet lifter with additional features:

-

- Integrated heavy-duty crane scale for real-time load monitoring.

- Radio control system for remote operation and data retrieval.

- On-site data printer for operational records and compliance tracking.

Types of sheet lifters

- Vacuum Sheet Lifters: Ideal for smooth, non-porous surfaces, using suction power to lift materials without damaging them.

- Mechanical Sheet Lifters: Suitable for heavy-duty applications, providing robust grip and versatility for rougher surfaces.

Both options are designed for ease of operation, reduced downtime, and maximum operator safety.

The choice depends on:

- Material type and surface condition

- Weight and dimensions of sheets

- Operational frequency and environment

Advantages of Using Crosby Airpes Sheet Lifters

Choosing Crosby Airpes means choosing:

✅ Enhanced Workplace Safety: Minimized manual handling risks.

✅ Boosted Productivity: Faster, more precise material handling.

✅ Custom Engineering: Solutions tailored to your specific workflow.

✅ Full compliance with international standards (OSHA Material Handling Guidelines & ISO Guidelines).

Our lifting systems are designed to meet the highest safety certifications, ensuring both reliability and regulatory compliance.

On-Demand Engineering: Tailored Sheet Lifting Solutions

Every sheet lifter is designed in close collaboration with you. Our engineers develop on-demand solutions—whether electromechanical or hydraulic—ensuring optimal performance for your specific processes.

With onboard PLCs, we guarantee smooth and safe operations, reducing product damage and downtime.

Sectors

Our lifters are ready to work in any sector involving sheets, especially the sheet metal sector and the sheet metal industry.

Success Story: Handling Engineering Project for U.K. Steel Plates Transformer

Crosby Airpes was tasked with providing a custom sheet lifter solution for a U.K.-based steel transformer project. The challenge: handling oversized and heavy steel plates with precision and safety.

The Solution:

- Designed a tailor-made sheet lifter system integrating both vacuum and mechanical lifting technologies.

- Ensured compliance with strict safety and efficiency standards.

The Result:

- Significantly improved handling times.

- Enhanced operator safety.

- A satisfied client with optimized operations.

Airpes: Global Experts in Lifting and Material Handling Solutions

At Airpes, we specialize in lifting systems, material handling equipment, and height safety solutions, providing tailor-made products for heavy-duty applications worldwide. With subsidiaries in Europe, the USA, and China, we proudly serve top clients across multiple industries.

From design and engineering to transportation, installation, and maintenance, we deliver comprehensive solutions for both onshore and offshore projects. Our team works closely with you to ensure the highest standards of safety, efficiency, and reliability.

Need a custom lifting solution?

Contact us today and let’s design the right sheet lifter for your business needs.

Frequently Asked Questions (FAQ) about Sheet Lifters

Vacuum lifters ensure non-damaging handling, ideal for sensitive materials, reducing scratches and deformations

Analyze factors like material type, surface texture, weight, and operational frequency. Contact Crosby Airpes for a tailored recommendation.

Regular inspection and preventive maintenance are recommended to ensure optimal performance and safety compliance.