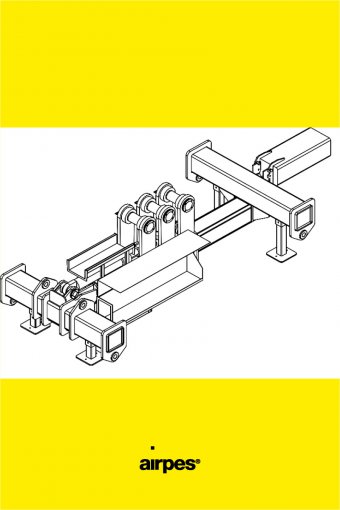

Lifting beams are designed to provide two or more points from the hook of the crane to lift and move loads. Is also a key element once you know the type of load you want to handle.

At Airpes we are experts in supply of all kind of beams from the most simple to the most complex ones, from 1,5t up to 490t, designed and manufactured for any kind of load and adapting them to the needs of the customer.

Today we bring you 6 safety tips to make sure that your lifting beam is working fine and that you and your company work in a safe environment.

What is a lifting beam?

A lifting beam (depending on the connecting points will be a spreader beam) at it most simple design is a solid piece of metal beam designed to be attached to a crane hoist by a rigging consisting of a chain or lifting wire.

It allows lifting objects whose weight is not equilibrated or objects that have a singular design that doesn’t allow to be lifted with a standard lifter. Basically lifting beams and spreader beams equilibrate the load to perform a safe lift. The material of construction is always metal in different alloys. This beam can be safely used for lifting materials of absolutely any kind.

It can also be used to move objects such as crates, shipping containers and in general any kind of object that enters within the crane lifting limits.

In many cases, a lifting beam is the only way to safely lift large and/or heavy objects. Once installed, a lifting beam should be checked regularly for proper operation and for integrity. Inspect for wear or failure and have it repaired or replaced as needed. With proper attention and care, this simple piece of equipment can make safe and efficient lifting possible for any job or challenge.

6 tips for a safe lifting beam handling

What are the tips and tricks to operate a lifting beam safely? From our experience, the key points you need to take care about are the following.

#1 – Choose the right type of lifting beam

First of all, before you choose the type of lifting beam that you need, you have to be sure about your project’s real needs.

You may need to:

- provide multiple lifting points

- handle out of unbalanced loads

- allow special load attachments

At Airpes we design many types of lifting beams and we can adapt their design to your company’s needs. We listen to our customers and create an on demand lifting beam that completely fits your needs. Just ask!

We can design the following lifting beams:

- Fixed lifting beams

- H lifting beams

- Moveable centre of gravity lifting beams

- Hydraulic powered lifting beams

- Lifting beams with levelling system

- Motorized rotating lifting beams

#2 – Make sure that your load is stable before operating

When the attachment points on the load are located above the center of gravity, the load will be surely stable. In case the lifting beam is connected to the load by slings, you will need to take care about the load, making it stable before operating.

#3 – Always keep in mind safe use instructions

Don’t forget about the basics of safety. Check our 10 tips for a safe handling and weighing including:

- qualified operators

- the best environment possible

- pre-operational inspection

- safety rules during lifting and operation

#4 – Test your lifting beam before first operations (and then during regularly inspections too)

Before you can put it to work, there’s nothing like a test in a safe environment. If you already have a lifting beam that you need to check, contact us and you can test it on our own test bench. That way you will make sure the safety and load limits of the machinery are still the same like when it was new.

#5 – Store and handle the lifting beam correctly

Storage is very important, since the way you keep your lifting equipment define how will they perform in the future. Make sure you do it correctly, so anytime you need to use it, it works fine.

You may be interested in: 10 safety precautions when using lifting equipment

#6 – Keep a regular maintenance of the lifting beam

There are no big requirements for the maintenance of lifting beams, but it is important to inspect it regularly to avoid any performance issues.

Contact us for anything related to lifting beams

If you need a specific new lifting beam design, improve a current lifting beam or doing the maintenance of your lifting beam, contact us now.

We are specialised in lifting equipment at all levels.

Other designs of lifting beams

Take a look at some of the other lifting beams projects we have installed around the world:[/vc_column_text]

-

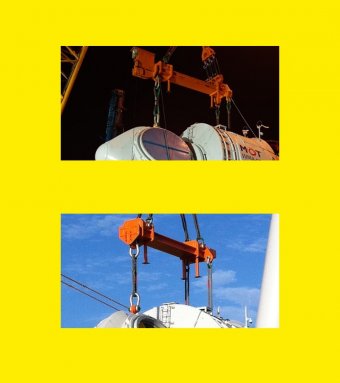

NACELLE LIFTING BEAM 80mTn

First Nacelle Lifting Beam from Airpes industries for the Wind Energy sector, after demonstrating fully its capabilities in the Lifting…NACELLE LIFTING BEAM 80mTnSeptember 22, 2020

-

RAIL LIFTING BEAM

Our rail spreader beam is a solution designed by Airpes to lift and handle train rails in an easy and…RAIL LIFTING BEAMSeptember 22, 2020

-

SPREADER BEAM

Airpes spreader beams are the perfect solution if you need a lifting beam and you don't have a low headroom…SPREADER BEAMSeptember 22, 2020