Building a wind turbine is a challenging process, especially considering that wind turbines have become taller and heavier in the last few years. Do you ever wonder how to construct a wind turbine? We explore some solutions that make the task easier and safer.

Wind turbine’s construction process

Turbine construction follows these steps:

- Building the tower is the first phase. The steel sections of the tower can be fabricated off-site at the factory, but they are usually assembled on-site. The parts are bolted together, and the tower remains in a horizontal position until it is placed. The tower is lifted in place with a crane, tighten the bolts, and test the stability when done.

- Next, the fiberglass nacelle is installed. The gearbox, main shaft, yaw control, and pitch control are factory assembled and mounted on the base. The nacelle is bolted to the equipment, which is then lifted to the finished tower and secured on-site. The nacelle is usually made of fiberglass and includes the gearbox and central driveshaft.

- Experiments have been carried out with new materials for blades. In commercial wind turbines, hollow fiberglass blades are used; aluminum and balsa wood are used. The aluminum blades are made by bolting aluminum sheets together, and the wooden blades are carved to create an aerodynamic propeller with a cross-section similar to an airplane wing. The production of fiberglass blades is relatively long. First, cut the mold in half, shaped like a blade. The inner surface of the mold is coated with a fiberglass-resin composite mixture. The fiberglass mix takes hours to dry, and inflatable air pockets in the mold help hold its shape. After the glass fibers are dried, the mold is opened, and the airbag is removed. The blade is cleaned, ground, the halves sealed, and then painted.

- The blades are usually bolted to the nacelle after being placed on the tower. Typically, three-pronged blades have two blades attached to the nacelle before being raised, and a third is bolted after the nacelle is in place.

- The wind turbine’s utility box and the wind farm’s electrical communication system are installed along with the rotor blades and nacelle placement.

You may be interested in: What are the five principal wind turbine parts?

Two solutions designed by Crosby Airpes for assembling a Wind Turbine

In Crosby Airpes, we are specialized in lifting solutions for the Wind Energy industry. During the last few years, wind turbines have become taller and heavier, looking to maximize the machine’s efficiency. Because of the increase in the size of every single part of the generator, the classic assembly methods soon become obsolete. In Crosby Airpes, we have specialized in lifting heavy parts from air generators.

1- Crosby Airpes solution to assembly wind turbine blades without a crane

After the tower has been built and the generator is in its place, it is time to install the blades that will generate the power. Sometimes wind turbine blades get damaged and need to be fixed or repaired. However, moving and installing a crane to manage the blades can be expensive and take time and resources.

In Crosby Airpes, we have designed a lifting method that uses the structure of the wind turbine as a support point. We have developed a solution that only with cables tightened to the base of the generator on the ground will lift (or descend in the case of reparations) the turbine blade in a few minutes. That allows the company to repair or replace a blade in just a fraction of the time it would need with the other methods.

How our craneless blade exchanging system works

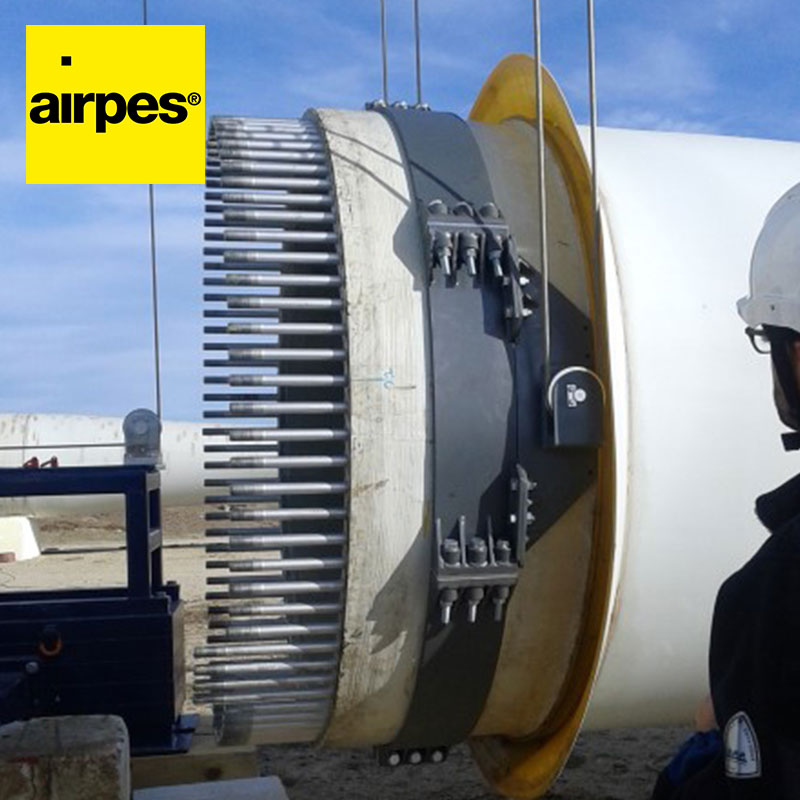

2- Crosby Airpes solution to “manually” rotate a wind generator: do it with our blade counterweight tool

When a blade has been assembled, it is time to turn the generator and get ready to assemble the next blade. However, turning the generator in this situation is not easy because you have a lot of weight on one side, making it difficult to rotate the axis. You need something powerful enough to do the job. In Crosby Airpes, we have designed a blade counterweight tool that will produce the necessary rotation force to turn the generator and orientate it to the position we need to assemble the blades.

The most advanced solutions for the wind energy industry

In Crosby Airpes, we are experts and have broad experience in engineering the lifting system that will help your wind energy company. Contact us now and let us know what you need.