In the dynamic and ever-evolving realm of renewable energy, wind turbines stand as colossal icons of progress towards a more electrified and carbon-free society. Harnessing the power of wind to generate electricity not only reduces our carbon footprint but also presents immense opportunities for employment and technological innovation. Amid this backdrop, the safety of wind energy workers takes center stage.

Ensuring their well-being requires a thorough understanding of essential safety precautions and protocols.

Related post: How do you set up a wind farm?

In this comprehensive guide, we present an in-depth overview of the crucial safety measures that wind energy workers must adhere to, promoting a secure working environment and minimizing risks.

Understanding the wind energy landscape difficulties

Before delving into safety precautions, it’s paramount to comprehend the landscape in which wind energy workers operate.

Wind turbines usually are located in areas with difficult access and where meteorology is harsh, so that makes it a difficult environment to work in.

Also these engineering marvels consist of multiple components, including the rotor, gearbox, generator, and tower, each with specific safety considerations.

9 safety considerations to take into account for wind turbine workers

The 9 most important safety precautions for wind energy workers are the following.

Proper training and certification of all the workers

Education and preparation form the cornerstone of wind turbine safety. All workers involved in wind energy operations should have received comprehensive and certified training on the field to know the intricacies of turbine components, emergency protocols and hazard recognition. Certification programs (like the ones offered by OSHA in the US) ensure that workers possess the necessary skills to navigate challenges effectively.

Heightened awareness of working at heights and the equipment needed for that

Working at substantial heights is a defining characteristic of wind turbine maintenance and repair. Fall protection systems, including harnesses, lanyards, and anchor points, are non-negotiable requirements. Regular inspection of these safety systems and perfect about how to use them is essential to maintain their efficacy.

Adherence to lockout-tagout procedures

Lockout-tagout procedures involve isolating energy sources before maintenance or repair work commences. Implementing these protocols prevents accidental start-up of machinery or electric shocks even on disconnected systems, safeguarding the well-being of workers who might be in close proximity.

Related post: Know the differences between onshore and offshore wind farms

High knowledge of electrical safety measures

Wind turbines house complex electrical systems. Proper training on electrical safety, including procedures for handling live circuits, grounding, and insulation testing, is paramount to prevent electrical accidents while testing, fixing, repairing or maintaining a wind turbine.

Having proper fire safety and fire emergency response protocols

Fire hazards are a reality in wind energy operations due to electrical components and the presence of lubricants inside of the turbines.

Adequate fire suppression systems and well-defined emergency response plans can minimize the danger of potential fires.

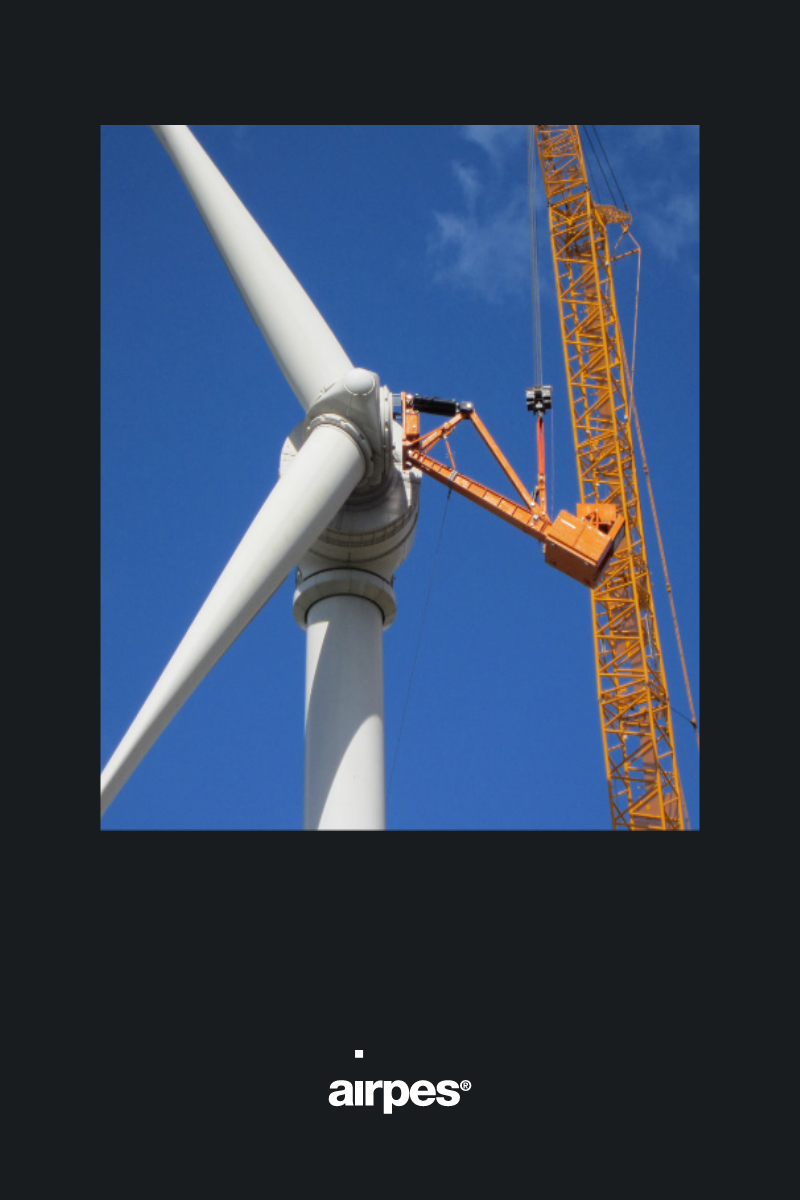

Safe lifting and rigging practices to reach high places

Lifting heavy components during maintenance or installation necessitates adherence to safe lifting practices. Rigging equipment, such as slings and shackles, should be inspected regularly to prevent failures during lifting operations.

Having proper weather awareness knowledge

Weather conditions significantly impact wind turbine operations. Monitoring weather forecasts and having well-defined evacuation plans (in case conditions change rapidly) are essential to prevent accidents during adverse weather events.

Effective communication protocols between technicians and ground team

Clear communication is vital in any workplace, but it becomes even more critical in wind energy operations, where coordination between workers is imperative. Radios, signal systems, and standardized communication protocols contribute to a safer work environment.

Personal protective equipment (PPE)

Wind energy workers must be equipped with appropriate PPE, including helmets, safety glasses, gloves, and steel-toed boots. PPE is a very important active safety measure, since they act as the first line of defense when accidents happen and can minimize damage o injury.

Work safer: use the best lifting equipment during installation or repairs of wind turbines

When it comes to installation and maintenance of wind turbines, the choice of lifting equipment can significantly impact efficiency and safety. In Crosby Airpes, we are renowned for designing lifting equipment tailored specifically for the wind energy industry. The unique challenges posed by working at heights and handling heavy turbine components require specialized solutions, and Crosby Airpes delivers precisely that.

Safety for your workers, efficiency for your maintenance or installation procedures.

Crosby Airpes offers a range of lifting equipment designed to meet the stringent demands of wind energy operations. Our solutions incorporate cutting-edge technology, ensuring precise control and minimizing the risks associated with lifting heavy loads.

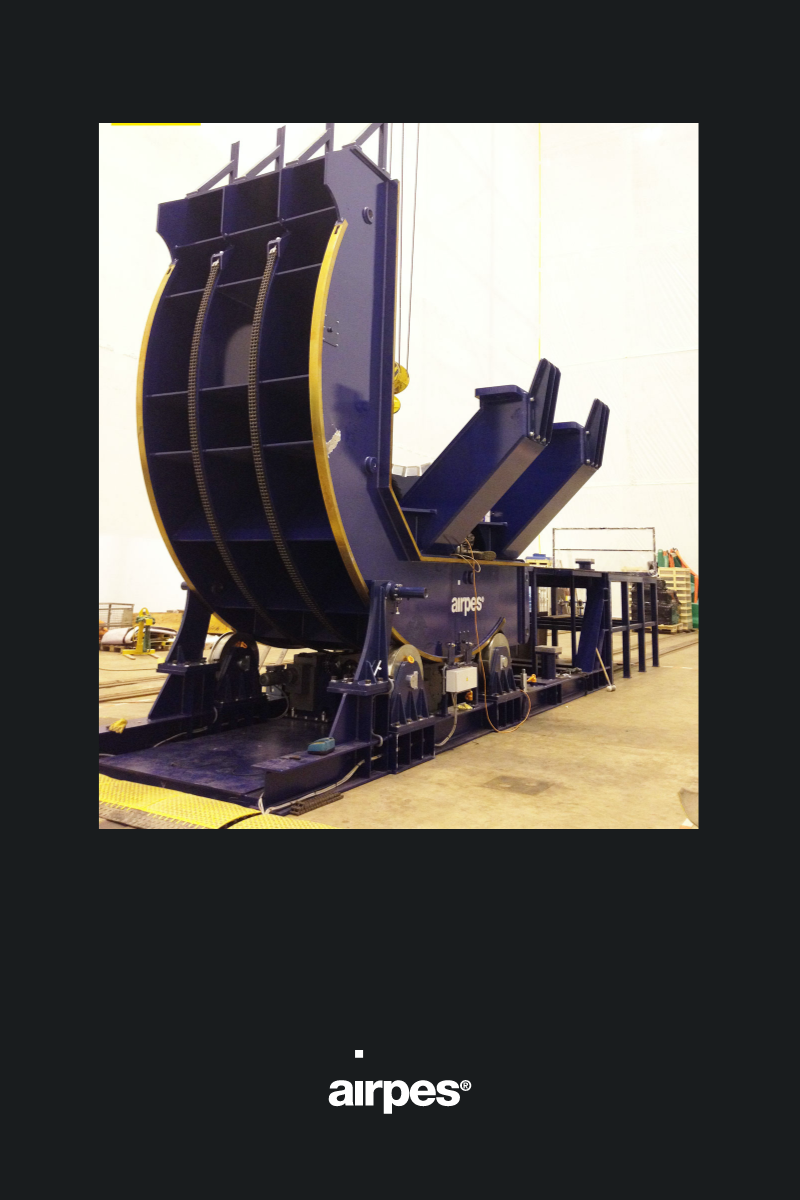

All our lifting solutions designed for wind energy include:

- Clamp installation tool

- Blade exchange system

- Lifting beam for blade installation

- Rotation tools

- Blade transportation tool

- Lifting beams and tools for wind turbines installation

- Installation tools for wind turbine towers

If you want to see them all, check our custom lifting solutions for the wind energy industry.

And remember that if it’s not on our portfolio, we can also design it for you: we make tailored lifting solutions for any need.

Conclusions

In the sector of wind energy, safety is not an option but an obligation. Wind turbines are extremely complex structures usually placed in remote places, so safety protocols are extremely important for workers and/or any individual on-site.

Implementing theessential wind turbine safety precautions described in this article ensures the well-being of workers and the optimal functioning of turbines. As the wind energy sector continues to expand, the industry’s commitment to safety remains steadfast. By prioritizing comprehensive training, stringent safety protocols, and incorporating advanced lifting equipment, we pave the way for a sustainable and secure future.

Discover some of our on demand solutions developed specifically for offshore wind farm projects.