PAPER COIL TONG

At Crosby Airpes, we design and manufacture paper coil tongs tailored to your specific operational needs. Our advanced lifting systems allow you to handle paper rolls safely, accurately, and efficiently, ensuring material integrity and operator safety throughout the process.

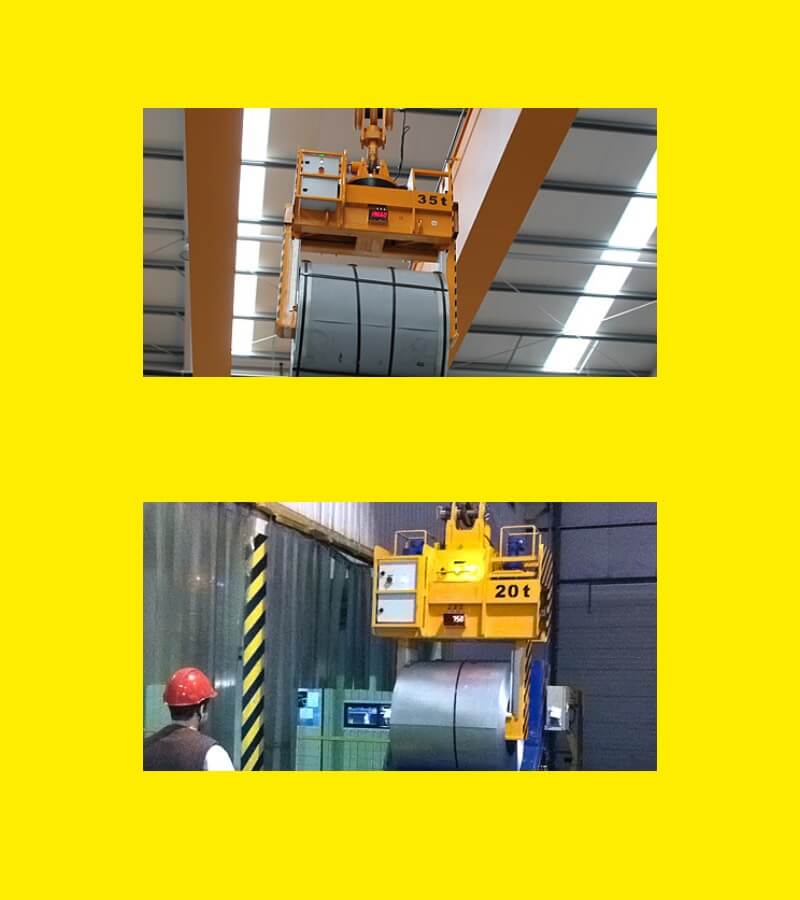

Thanks to their modular and adaptable design, our paper coil tongs integrate seamlessly into overhead cranes, lifting systems, or production lines. Whether you’re in the paper manufacturing, logistics, or packaging industry, this is the ultimate solution to lift heavy paper coils without compromising productivity.

Why Choose Crosby Airpes’ Paper Coil Tong?

- Custom-built based on your coil’s size, weight, and application.

- High load capacity: up to 5 tons — ideal for jumbo paper coils.

- Optional rotatable tong: enables both horizontal and vertical positioning for easy storage and transport.

- Maximum safety: compliant with Directive 2006/42/EC and other global safety standards.

With Crosby Airpes, you get a reliable and robust solution engineered to boost productivity and minimize operational risks.

Technical Features of the Paper Coil Tong

- Manufactured in S355 J2 + N grade steel for enhanced strength and durability.

- High-precision hydraulic system for smooth, safe operation.

- Optional coil rotation feature for efficient load orientation.

- Integrated electronics (PLC, sensors) for intelligent, secure control.

- Protective pads and coatings to prevent damage to paper coils.

- Fully customizable: dimensions, lifting capacity, control systems, and compatibility with your current equipment.

Coil catching systems

As a new feature this paper coil tong includes two independent coil catching systems for versatile handling. These systems allow the tong to operate both when the coil incorporates an axis for laminator placement and when it does not, ensuring adaptability to different handling requirements. This versatility makes it an ideal solution for various paper processing and manufacturing applications, optimizing efficiency in material transport and storage.

To enhance operator safety, the tong is equipped with advanced anti opening leg security systems, preventing accidental coil release during handling. Additionally, its heavy-duty construction ensures long-term durability, while its customizable design allows it to be tailored to meet specific industry requirements, providing reliability and efficiency in paper roll transportation.

Industry Applications of Our Paper Coil Tong

Our paper coil tong is the ideal equipment for:

- Paper and cardboard mills

- Printing and packaging companies

- Logistics centers handling heavy paper rolls

It is designed as a heavy-duty roll lifting machine, tailored to each operation’s specific requirements and built to streamline loading and unloading times.

Explore our complementary coil handling systems:

Engineered-to-Order: custom solutions for your workflow

Every paper coil tong is developed in collaboration with your technical team, considering:

- Coil specifications (material, size, weight)

- Operating conditions and lifting environment

- Integration with your existing lifting systems

Whether you require a rotating paper coil tong or a standard fixed version, we guarantee optimal performance, improved workflow, and maximum safety.

Get a Custom Quote for Your Paper Coil Tong

At Crosby Airpes, we create tailor-made solutions to handle paper coils safely and efficiently.

Request your custom quote now and optimize your paper coil handling process.

FAQs – Everything About Paper Coil Tongs

What is a paper coil tong?

A paper coil tong is a lifting accessory designed to grip, lift, and move paper rolls safely without causing any damage, ensuring operational efficiency.

What’s the purpose of the rotating coil tong?

It enables rotation between horizontal and vertical positions, making it easier to store, transport, or feed paper coils into production lines.

What kind of maintenance does it require?

We recommend regular preventive checks: hydraulic system inspections, sensor and electronics testing, and fine-tuning of all moving parts to ensure continued safe operation.