Have you seen how big the cranes used to build large infrastructures, skyscrapers, or wind farms can be?

Mega cranes are used in the remotest places, and their construction is deceptively hard work. The individual steel elements are huge, but the crane needs millimetric precision in its assembly. Faced with this challenge, engineers push the limits of physics in their design.

Discover next all the secrets of mega cranes.

What is a mega crane used for?

A mega crane can lift hundreds of tons, can be hundreds of meters high, and its weight can be gigantic. One of their pieces alone can weigh hundreds of kilos.

Mega cranes are used all over the world in construction, harbors, and industrial plants, in opencast mining, in inner cities, or in the construction of wind turbines.

Mega cranes are available in different configurations. Different heights are possible depending on the requirements on site.

They are characterized by their huge chains, a gigantic boom, and be capable of lifting incredibly heavy loads. Mega cranes are so high, they need to have a flashing lamp so that the crane can be seen from the air by airplanes and helicopters.

You may be interested in: Automatic cranes characteristics and advantages

Which types of mega cranes exist?

Mobile cranes

This kind of cranes can be used anywhere because they normally have the substructure of a conventional truck. The advantage is that the crane can be transported quickly from one point to another, and it can be set up and dismantled in a relatively short time. However, they can usually lift significantly less weight than large crawler cranes.

Caterpillar cranes or crawler cranes

These are huge cranes, far too big for smaller applications, such as construction sites in narrow residential areas. They are also mobile, but, they don’t have a truck substructure. One of the largest parts of a crawler crane is the caterpillar track that allows movement.

That doesn’t mean that the crane is one piece. Normally, it is made up of different crane components that must be assembled where it will be used.

Mega crane engineering

Designing a mega crane

The construction of a crane starts with the study of the customer’s needs. Next, the manufacturer needs to make calculations and use computer programs to design it. Every project is a challenge and engineers are constantly trying to improve existing cranes to raise the maximum load and reduce weak points, but you can’t cheat physical limits.

During design, the location where the crane will be used must also be taken into account. Is there enough space for the crane? Is the terrain suitable?

Manufacturing a mega crane

Crane manufacturers work with production lines, similar to the automotive industry ones. They used tons of steel and usually use magnet solutions to move the materials.

Usually, mega cranes have a lot of big parts that must be put together. This is challenging because huge amounts of steel need to be moved. The individual elements are moved by an auxiliary crane.

You may be interested in: ISO certifications for cranes

How are cranes transported?

As mentioned above, some cranes are mobile and are mounted on top of trucks. But some cranes are so large that they must be transported in pieces. In that case, they are assembled where the lifting operation is performed.

These cranes can be fixed or mobile if they have a crawler track.

Assembling a mega crane

Every crane deployment is different, but assembling needs precision. If a crane component is not straight, that would be fatal. All huge crane parts have to be controlled precisely. For this purpose, the cranes are equipped with highly sensitive electronics. Computers monitor the entire operation. Above all, they ensure that the crane is stable under all conditions.

The hoisting rope is just as important. It alone can weigh several tones. The rope is subjected to severe stresses during the operation to include it in the structure of the crane. Because of this, it needs to be regularly maintained and cared for with rope grease.

Erection of a mega crane

Once the crane is assembled, it has to be erected. This is a critical moment during construction. For doing it, they usually use a huge boom that moves upwards very slowly. In the middle of the process, the hoisting rope can be fed into the pulley with the crane hook. Then, the erection of the crane can be resumed.

You may be interested in: The importance of crane deflection limits in the design of lifting devices

Safety is a must when operating a mega crane

Operators of mega cranes need specific training, immense expertise and must know the equipment and its functions in detail. They check out every screw and every bolt. They know how to put the crane through its pieces. All crane components are connected with heavy bolts and they are secured with an oversized safety slip pin.

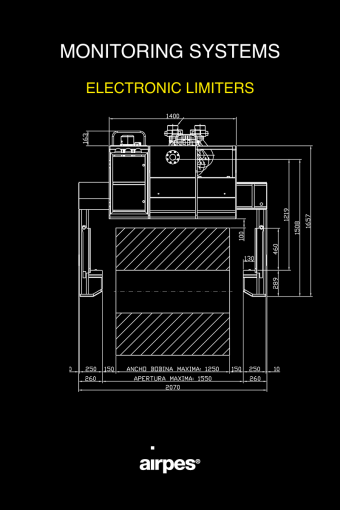

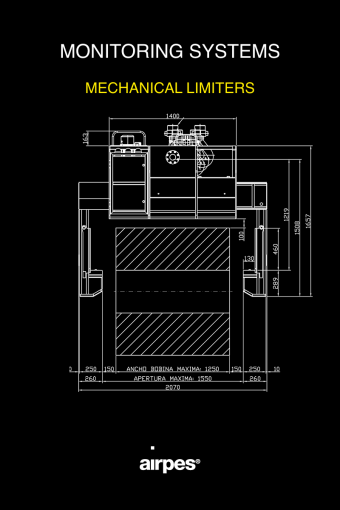

Safety is a must. The cranes require appropriate counterweights that can be changed according to the weight of the load. They must also have overload protection equipment, such as a hoist limit weight, a safety device to prevent the crane hook block from bumping against the book if the crane operator pulls it up too far. There are mechanical limiters and electronic limiters.

Bellow the hook crane equipment for all types of cranes

Crosby Airpes specializes in the design and manufacture of lifting equipment for any type of crane. Do you need custom crane equipment? Contact us.