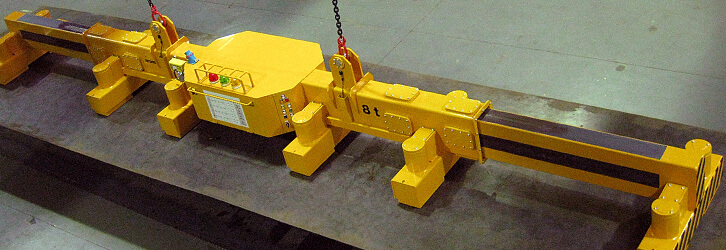

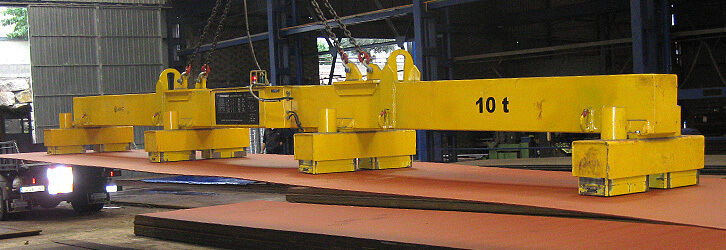

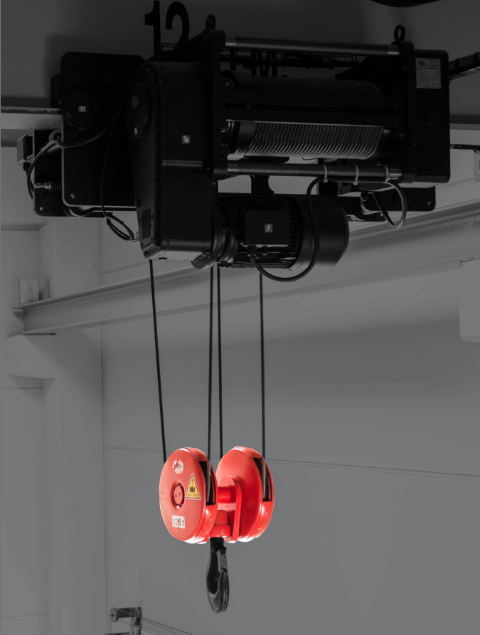

Magnetic Lifting Equipment for maximum efficiency

Looking for a safe, powerful, and efficient solution to handle heavy steel loads? Our electropermanent magnet combines the advantages of permanent and electromagnets, delivering magnetic lifting equipment that maximizes safety, reduces energy consumption, and ensures productivity without compromise.

Contact us today to learn how our electropermanent magnet solutions can optimize your operations.

Why choose an Electropermanent Magnet for your lifting operations?

The electropermanent magnet is the optimal choice for operations requiring robust, reliable, and sustainable solutions for lifting and handling ferrous materials. Unlike conventional magnets, it does not require continuous electric power to hold the load. It only uses electricity at the moment of activation and deactivation, offering clear advantages:

-

Maximum safety even in case of power failure.

-

Up to 90% lower energy consumption compared to traditional systems.

-

Versatility to handle plates, tubes, beams, irregular parts, and more.

-

Durable and maintenance-free operation.

We some of the world’s most prestigious companies in shipbuilding, steel production, construction, and logistics, delivering tailor-made solutions trusted by industry leaders such as Siemens Gamesa, ArcelorMittal, and Navantia.

Do you need our expertise in Electropermanent Magnets? Contact us

If you’re ready to move forward, fill in your specifications in the form below.

If you’d prefer to have one of our experts contact you and provide personalized assistance, you can reach us here.

Looking for the perfect Electropermanent Magnet?

Fill out the form and get a custom offer

Just hit play and follow the steps to send us your custom inquiry, our team can send you a tailored quote based on your lifting needs.

It’s quick and easy!

Key features of our Electropermanent Magnetic Lifting Equipment

Our electropermanent magnets are designed to meet your specific needs, providing superior performance and reliability in all conditions. Key features include:

-

High safety and reliability in demanding environments.

-

Minimal energy consumption thanks to advanced engineering.

-

Fully customizable to your load dimensions and weight.

- Modular system design: active modules and magnets can be increased or reduced according to the particularity of each magnet beam and operation, ensuring maximum flexibility and efficiency.

-

Compact, maintenance-free design.

-

Suitable for a wide range of materials and shapes.

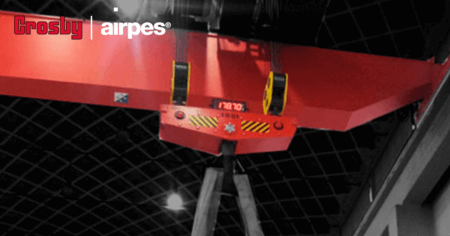

Every unit is manufactured in compliance with the strictest international standards, backed by the expertise and global reach of Crosby Airpes.

Technical Specifications

To help you plan your projects, here is an overview of typical technical specifications:

| Specification | Typical Value |

|---|---|

| Lifting capacity | Up to several tons |

| Power supply | Required only at switching |

| Cycle time | Fast, within seconds |

| Dimensions | Fully customizable |

| Operating temperature range | As specified per project |

Applications of Electropermanent Magnets

Electropermanent magnets from Crosby Airpes are designed to meet the rigorous demands of diverse industrial sectors. Their combination of safety, efficiency, and adaptability makes them the ideal choice for a wide range of lifting and handling scenarios.

-

Steel Service Centers and Warehouses:

Efficient stacking, destacking, and transportation of steel plates, sheets, and slabs without damaging the material surface or requiring additional clamps or slings. -

Shipyards:

Handling large steel plates and sections for ship hull construction and repair, where secure lifting in windy or unstable conditions is critical. -

Structural Steel Fabrication:

Moving and positioning beams, pipes, and profiles of various shapes during assembly or welding operations with precision and safety. -

Railway and Transportation Industries:

Lifting rails, bogies, and structural parts quickly and securely, optimizing turnaround times and reducing manual intervention. -

Heavy Machinery Manufacturing:

Transporting large, irregularly shaped components where conventional lifting systems would be impractical or unsafe. -

Energy and Wind Power Sector:

Handling large steel components for wind turbine towers and nacelles, where high lifting capacity and reliability are essential for productivity and worker safety. -

Metal Recycling and Scrap Yards:

Picking and sorting ferrous materials efficiently, even in harsh and dusty environments, without risk of load drop in case of power failure.

Our engineering team can assist you in evaluating your specific workflow and recommending the optimal electropermanent magnet configuration to improve your operational efficiency, safety, and cost-effectiveness.

25 YEAR EXPERIENCE

Crosby Airpes has been designing and engineering lifting solutions for more than 25 years.

Trust us for any kind of project:

petrochemical, hydraulic, transport… We will just do it. We are constantly improving our designs, manufacturing, marketing and QC processes in every project.

The quality of these processes qualifies airpes® to obtain UNE-EN, ISO9001 by the prestigious German Quality Control Organization TUV.

Why partner with us?

For over two decades, Crosby Airpes has delivered innovative and reliable magnetic lifting equipment solutions to clients worldwide. We have become a trusted partner to some of the most demanding industries by combining engineering excellence with deep knowledge of lifting challenges.

-

Global presence with experience in large-scale, complex projects.

-

Custom-engineered solutions to meet precise requirements.

-

Commitment to safety, innovation, and superior customer support.

Speak with our experts today to take your lifting operations to the next level.

Certifications and Compliance

All our lifting systems, including our Electropermanent magnets, are manufactured in full compliance with the European Union’s safety and quality directives. Our design, manufacturing, and quality control processes are certified under UNE-EN ISO 9001:2000 by TÜV, one of the world’s most recognized certification bodies.

Each Magnetic lifting solution comes with complete technical documentation, including:

- Proof load test results

- Design safety factors

- Compliance and inspection certificates

This ensures full traceability and quality assurance for every product delivered.

Related Products

-

LIFTING ELECTRO MAGNET

We have the most interesting products in the industrial electromagnet field because we are in charge of the whole lifting electromagnet design, but…LIFTING ELECTRO MAGNETSeptember 22, 2020

Enhance your lifting operations with us

If your operation requires safe, efficient, and reliable lifting of ferrous materials, our electropermanent magnets provide a proven, durable solution engineered to meet your exact requirements.

Contact our team today to request a personalized quote and learn how our precision-engineered equipment can optimize your operations.

CONTACT US

FAQS

What is an electropermanent magnet and how does it work?

An electropermanent magnet is a lifting device that combines permanent magnets and electromagnets to handle ferrous materials. It uses a brief electrical current only to activate or deactivate the magnetic field. Once activated, it securely holds the load without requiring continuous power, ensuring both efficiency and safety.

Is an electropermanent magnet safe if the power supply fails?

Yes. Electropermanent magnets remain securely engaged even in the event of a power failure. Since they do not rely on continuous electricity to hold the load, they provide a higher level of safety compared to traditional electromagnets.

What are the advantages of using an electropermanent magnet over other lifting solutions?

Electropermanent magnets offer several key advantages:

-

They consume significantly less energy than electromagnets.

-

They ensure load security even during power outages.

-

They provide faster cycle times and require minimal maintenance.

-

They can be customized to suit specific load shapes and operational needs.

Does an electropermanent magnet require regular maintenance?

Electropermanent magnets are designed to be virtually maintenance-free. Their robust, sealed construction minimizes wear and tear, reducing downtime and operating costs over time. However, periodic inspections are recommended to ensure optimal performance.

Can an electropermanent magnet be customized for my specific operation?

Yes. Crosby Airpes engineers and manufactures electropermanent magnets tailored to your exact requirements. The modular system allows the number and arrangement of magnets to be adjusted based on the load dimensions, weight, and beam configuration.

What materials can be lifted with an electropermanent magnet?

Electropermanent magnets are designed to lift a wide range of ferrous materials, including steel plates, sheets, slabs, beams, pipes, and other iron-based components. They can also handle irregularly shaped and uneven loads efficiently.

Crosby Airpes solutions

LATEST POSTS ON THE BLOG

Discover our brand new developments, events, get posted of our activity.

- Coil Transfercar: handle industry coils safelyCoil transfer cars are mobile platforms for the safe transport of industrial coils...

- Industrial Load Turning Devices: how to choose the right solutionNot all heavy loads are the same and not all turning devices should...

- Industrial scale safety: essential measures for crane scales and lifting equipmentWe review six safety precautions to keep in mind when using a crane...

- Difference between onshore and offshore wind farmsOnshore and offshore wind energy present similarities and differences. We analyze the challenges...