Hydraulic lifting tools are essential in industrial workplaces and warehouses, operated via pumps, using oil solutions and pistons to apply and distribute pressure with or without external power sources.

Hydraulic systems are closed fluid-based systems that use pressurized incompressible liquids as transmission media. A hydraulic system uses fluid under pressure to power machinery or to move mechanical components. Pressure applied to liquids enclosed in a vessel is used as the prime mover to control objects’ motion and force. Specially designed fluid systems can provide both linear and rotary motions.

We will analyze everything you need to know about hydraulic tools and how they can be applied to lifting equipment.

What are the applications for hydraulics systems?

Hydraulic systems are so ubiquitous that you may interact with a hydraulic-based system multiple times throughout the day without even realizing it.

Hydraulics is a mechanical function that is acted upon by fluid pressure. In hydraulic-based systems, motion is created by an enclosed pumping fluid, usually a hydraulic cylinder that moves a piston.

Hydraulic systems have many applications. They are widely used in the automotive industry, from braking systems to power steering. However, they are also used in construction, manufacturing, aircraft, and various lifting and handling solutions.

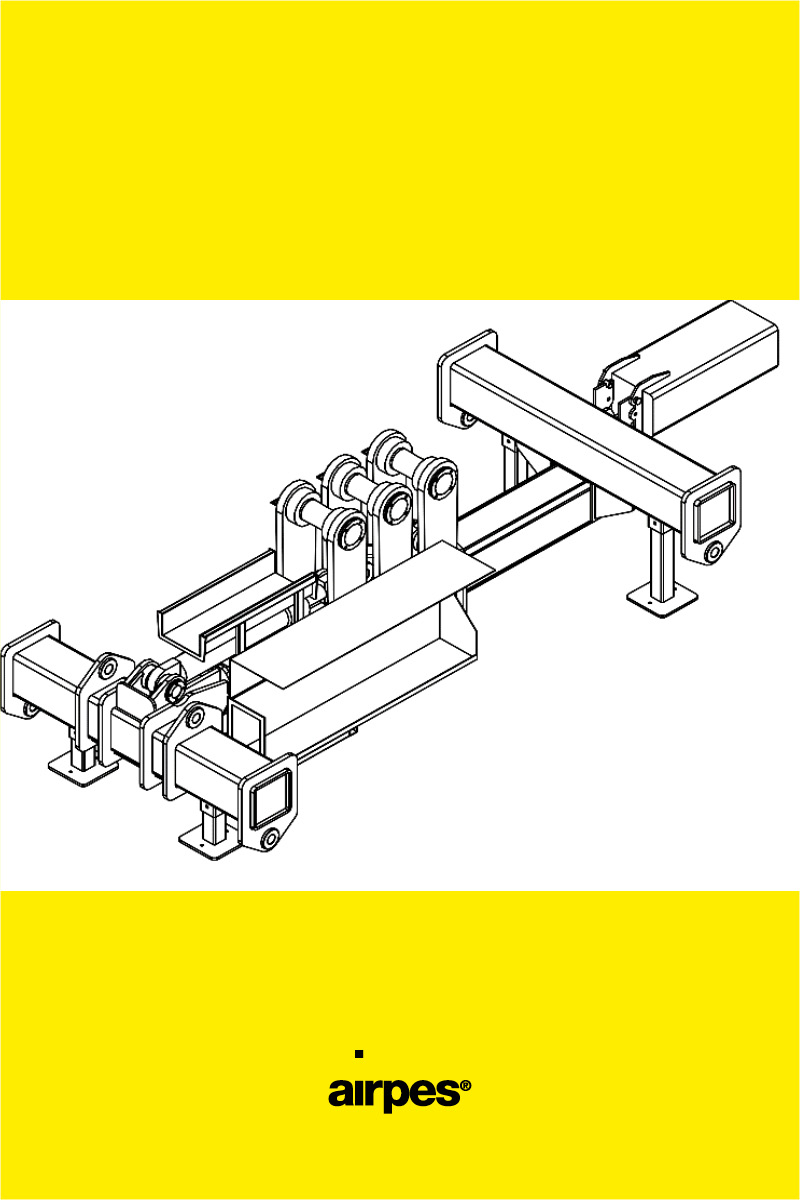

Discover our hydraulic adjustable lifting beam

Hydraulic cylinders: the power source in hydraulic lifting tools

Hydraulic cylinders contain the pressurized oil that allows force and motion to be applied in hydraulic tools. They can have single-acting or double-acting forms, using force in one direction or simultaneously horizontally and vertically.

A hydraulic cylinder’s size, capacity, and stroke size may vary to make it compatible with tools with differing clearances for attachment, changing its lifting capacity and the distance from which it can move something.

Connecting hydraulic cylinders to the lifting tool

Using a hydraulic lift system is not as simple as attaching the cylinder to the back and getting ready to use it. To securely attach the cylinders to the tool, they must be connected with hydraulic hoses, the correct couplers, valves, and manifolds to control the flow of pressure correctly, and gauges to monitor the pressure used.

Generating the pressure for hydraulic lifting tools

Hydraulic cylinders are connected to hand-operated pumps, electric or powered pumps to create the pressure needed and be activated.

Hydraulic pumps move hydraulic tools and cylinders. Many devices have built-in hydraulic hand or foot pumps, but separate hand or electric pumps can also be used as attachments for other tools.

Essentially, a pump pushes pressure through an air cylinder or tool to achieve the desired effect, whether lifting, pushing, clamping, or any other typical hydraulic function.

Discover how we use hydraulics in lifting tongs design.

Hydraulics systems vs. pneumatic systems

Hydraulics systems and pneumatic systems are similar in function. Both systems use pressurized fluid power, but the main difference is that hydraulics use liquids and pneumatics use gasses.

Hydraulic systems are capable of higher pressures: up to 10,000 psi, while pneumatic systems are around 100 psi. This pressure is due to the incompressibility of the fluid, allowing for greater power transfer and higher efficiency since no energy is lost through compression except when air enters the hydraulic lines. Hydraulic oil also lubricates, cools, and transmits hydraulic power. Pneumatics are less versatile and require separate oil lubrication, which can mess up the air pressure.

The design and control of pneumatics are more straightforward and safer (with a lower risk of fire) partly because the compressibility of gas-absorbing shock absorbers protects the mechanism.

Crosby Airpes’ hydraulic lifting solutions

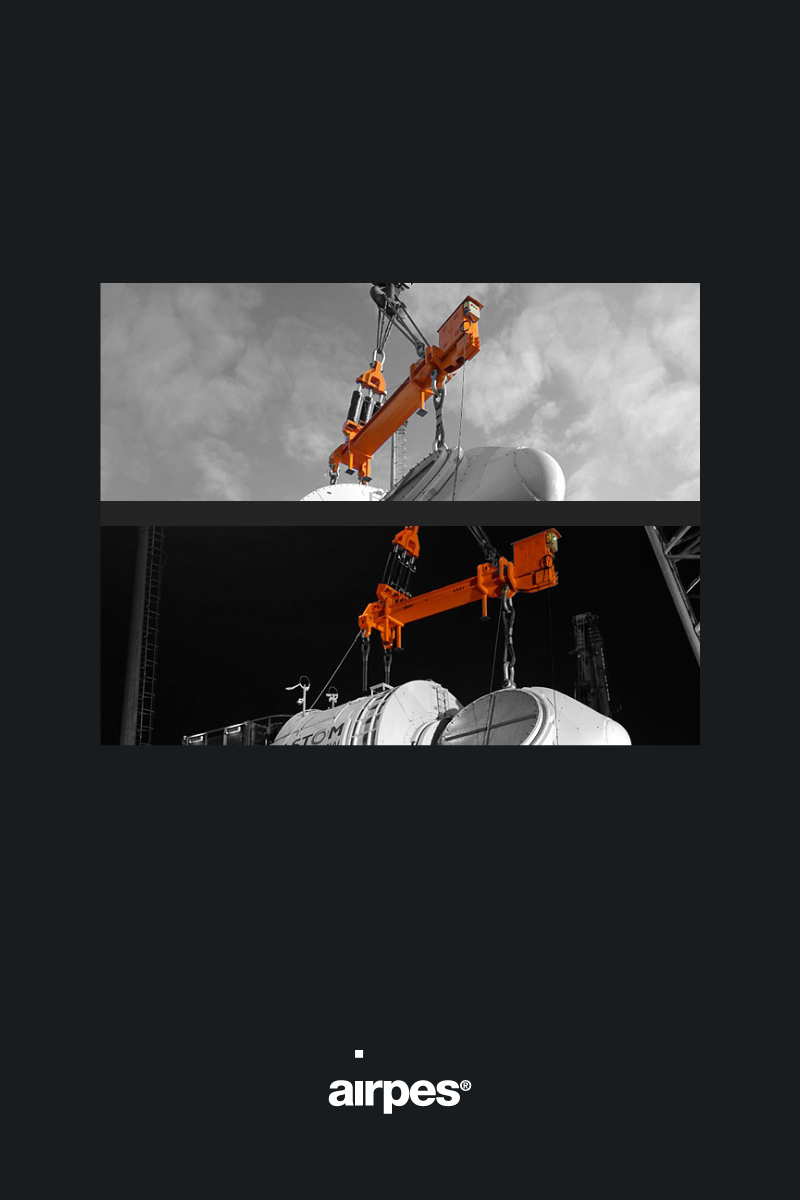

We design our solutions for safety and quality and stand behind our products. Our tools are primarily used to lift, tow, and distribute heavy equipment and loads weighing hundreds of tons in wind energy, metallurgical, or shipbuilding industries.

Discover some of our wind energy projects with hydraulic systems: