The automotive industry involves a lot of physical efforts and strategies for the operators in charge. Sometimes, these efforts are more than the capacity and require an effort that is imposible to carry, this give rise to lifting systems.

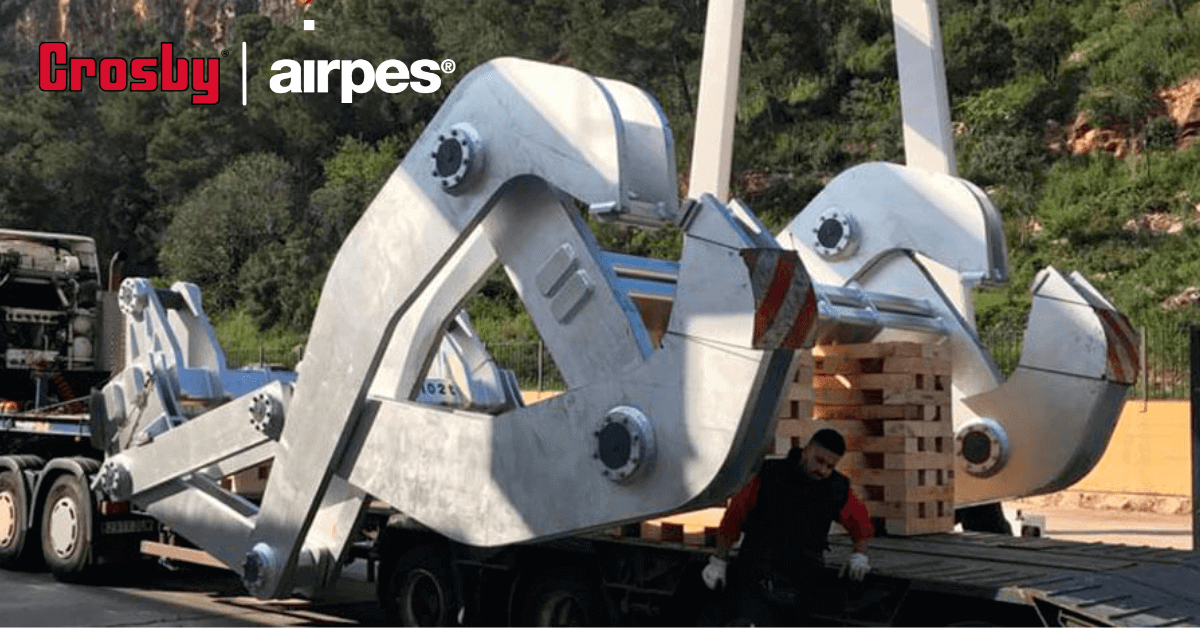

Moving parts is an arduous task, especially to do it quickly and efficiently. Crosby Airpes offers you lifting systems that allow the displacement of loads and help to minimize the negative effects that the manual activities of the operators bring with them.

From the experience that characterizes us, we offer you designs and developments of lifting systems that cover your needs, providing you with flexible, fast, easy to implement and reliable solutions. The care of the machinery being transported is just as important as the care of the operators in charge of it. That is why at Crosby Airpes we take care of adapting to any transport system or element to be transported.

We present in this post some of the most used lifting systems in the automotive industry.

Types of lifting systems for the automotive industry

Among the types of lifting systems present in the market you can find several options, we are going to tell you about the most important types of lifting machines:

Types of hydraulic lifts for cars

Hydraulic lifts are used to lift heavy objects, frequently used in the automotive industry since they allow working with cars of any size and/or model. You can find them in different types:

- Single column. They are very light lifts, called mono-columns, their frequent use is anchored to the floor and ceiling. They are used in the production and maintenance systems of industrial plants.

- Two columns. These lifts are designed to lift vehicles of all types, they support a great deal of weight thanks to their strong columns and stabilizing support arms. They are available as symmetrical and asymmetrical, what varies are the support arms.

- Four columns. Mostly used for industrial vehicles for offering greater versatility in the case of weight capacity, it has four strong columns. Some models have ramps that help the entry and exit of vehicles. They can represent a solution in the case of parking lots due to their storage capacity.

- Scissor lift. Used to lift engines or motorcycles. The mechanism used is accordion type, which improves the load. In the market you will find different models that vary according to capacity and height.

- Spider lift. They are aerial lifts that are very versatile and agile, which allows them wide applicability in the automotive sector, can handle heights from 49 to 160 feet, and are present in different models with tracked or wheeled chassis, and can also rotate up to 360 °.

How to choose the right hydraulic lift?

From Crosby Airpes we recommend that when purchasing a hydraulic lift you take into account:

- The type of material it was manufactured with, evaluating the resistance and safety it provides.

- The height of elevation that it handles, both low and maximum. That will give you a range of action in the models and types of vehicles you want to work.

- The weight it can support, so you will know if it fits or not to your needs.

- The use it will be given.

Tube lifts for big loads:

Tube lifters are used to support heavy loads. They use vacuum technology, which allows the operation of clamping and lifting, making the use of manipulators, chains or cables essential for picking up and lifting the load. It operates with air inlet and outlet, which allows lifting (high vacuum) and lowering (low vacuum) the device, it is also easy to control by the user thanks to a valve that allows it. You can find in the market different models, varying the use to be given, the load to be handled.

Crane merchandising systems:

They vary depending on their use and the load to be supported, we can find from overhead cranes, jib cranes and hoists.

As well, crane solutions are the merchandising specialty of Crosby Airpes, and we are able to install any lifting system in your current crane, for automotive repair or building industry.

- Overhead cranes are very useful for lifting and moving heavy parts, both horizontally and vertically. They can be operated remotely, wired or wireless, and also through a control cabin. Several types of bridge cranes are available on the market, among which monorail or bi-rail cranes stand out.

- Monorail bridge crane, in this case it has a single girder, resulting in a simple and lightweight system.

- Double girder bridge crane, in this case there are two girders, thus having a greater load capacity, speed, precision and safety of movements.

- Jib cranes, also known as jib cranes, are lifting devices consisting of a column, a slewing arm unit and an electric hoist. They can be column, mast and wall-mounted.

- Column jib cranes are designed to be self-supporting and can rotate up to 360°. They generally have a lifting capacity of 1 to 5 tons, and some of them can handle up to 15 tons.

- Mast type jib cranes have many uses and it will depend on your work environment whether or not it is convenient for you to acquire one. They can be of the drop and full cantilever type. It has a lifting capacity of 1 to 5 tons.

- Wall-mounted slewing crane, it is placed on the wall, has a rotation of up to 180°, uses very little space for its mobilization, is more economical, and has a lifting capacity of 5 tons.

- Hoists are machines used to move or lift heavy loads, they are made up of two sets of pulleys, one with mobility and the other fixed. They are widely used in the automotive sector due to the variety of loads to be handled, through cables, chains or ropes. They can use their power through manual force, electricity or levers.

Click here to know more about lifting equipment for cranes..

In Crosby Airpes, we know the relevance of the automotive industry worldwide, we know that it is one of the sectors that boosts the economy, by the income received and the jobs it generates. That’s why making known the lifting systems is a priority for us, because you can improve the work done quickly and ergonomically, moving tons will no longer be a problem, just study the needs of your company and we will advise you.

Looking for assistance on lifting systems for the automotive industry?

If you are looking for a reliable partner on lifting systems for the automotive industry, trust Crosby Airpes as your best option when it comes to cranes and different types of lifting systems, installation and logistics.

Contact us for more information in our contact page.