Our solutions include specialized clamps for safely lifting large boulders.

Lifting tongs are versatile devices that we can adapt to the needs of every client. Delivering the most amazing lifting solutions is not easy. Each type of lifting equipment must fulfill specific needs we must consider when manufacturing them. We must consider every critical variable to obtain the most suitable tool for each client. The system is designed to be user-friendly for any operator, ensuring ease of use and efficiency in various work environments.

A rock lifting tong is a piece of equipment specifically designed for handling blocks of stone, marble, and similar materials using our classic coil lifting tong design as a base. Discover the on-demand solution Crosby Airpes intended for a company in the extractive sector, using our tongs heavy duty to meet the most demanding lifting requirements.

Lifting tongs for the extractive industry

For a company in the extractive sector, we designed adjustable lifting tongs to move blocks of stone, marble, and similar materials used in construction. The design of these clamps starts from the base of the Crosby Airpes coil lifting tongs, with specific adaptations so that the machine can carry out the operations requested by the client. Our rocklift solution is ideal for handling heavy materials efficiently in this industry.

These tongs also feature an easy chain hook system, allowing quick attachment and detachment for improved efficiency.

Adjustable lifting tongs available for rock blocks

The client needed lifting tongs to handle and manipulate marble and stone blocks extracted from a quarry and stored in the open air.

Since the type of material the company works with is not affected by weather, it can be stored anywhere without needing an enclosed space or complex security, custody, or preservation system.

This storage system is the most convenient, practical, and economically viable for any company in the sector: this saves costs on the maintenance of buildings and related infrastructure. Our grapple system is perfect for handling such heavy materials in an open storage environment, including boulder tuff.

One of our types of rock lifter grapple

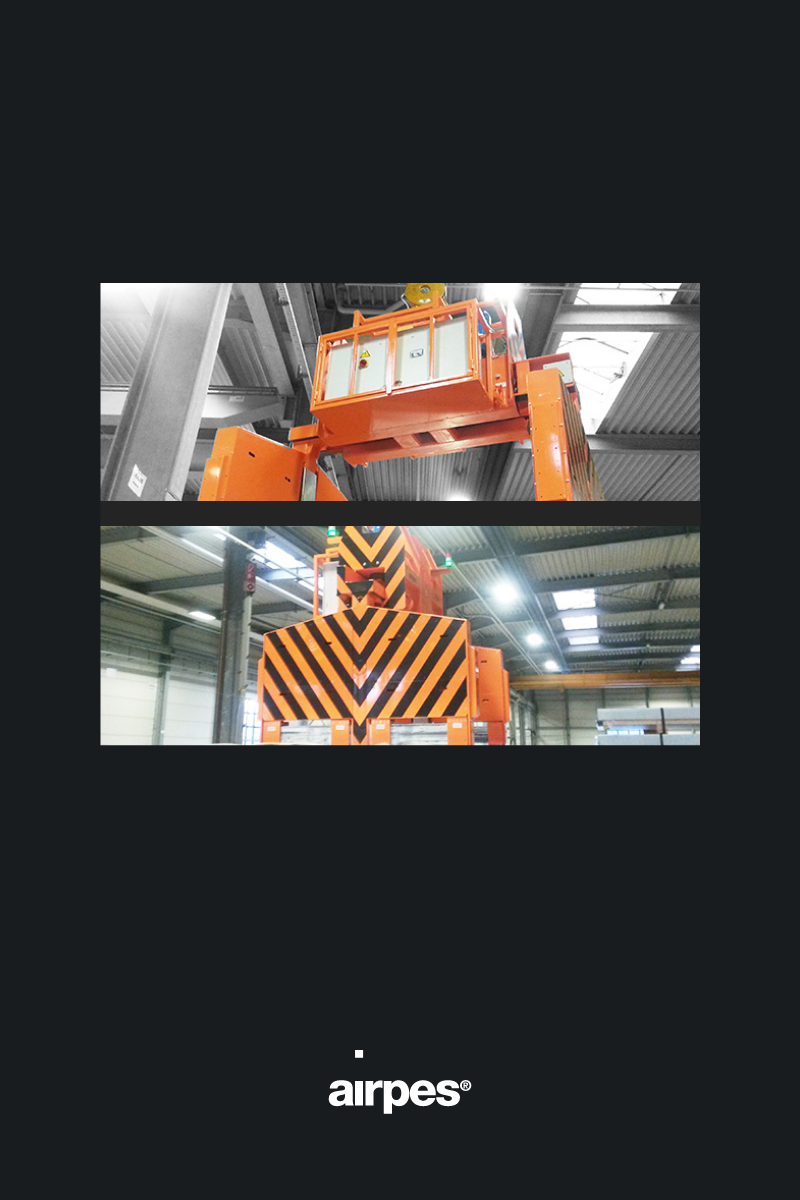

Clamp installed on a gantry crane with wheels

For manipulating the blocks of material, the customer has a gantry crane with wheels powered by electric motors that can move freely throughout the storage site.

The gantry crane from our catalog can support weights of up to 42 tons. In this crane has been installed the lifting clamp, which has the following characteristics in order to make the client satisfied with the service that we make:

- Lifting capacity up to 25 tons for rock lifts

- Reinforced and waterproofed structure against water and dust, designed to resist rust and corrosion in all weather conditions

- Ability to work outdoors and under all weather conditions

- Rotary hoist and beam for reorienting parts while in the air

- Adjustable arms with an opening and closing system to lift blocks of different widths

- Rotating arms: some pieces are not symmetrical, and one or both arms must be oriented at a different angle to lift such blocks.

- Anti-opening safety system: The clamp will not open if it detects that the object held by the rock tongs is not on the ground.

- An industrial radio-controlled system allows the machine to be operated from the ground.

- The lifting clamp also features rock retaining capabilities, ensuring that large stones and materials remain securely in place during lifting operations. Additionally, the clamp is designed to handle debris that may accumulate around the blocks during lifting.

One of our best rock grabber tools

The experience of a professional team

It is important to take into account that Crosby Airpes has been in charge, as in all the projects we make, of the study, design, and manufacture of the lifting clamp based on the client’s requests and needs. This implication allows us to provide customized solutions, such as clamps with hardened teeth for enhanced grip and durability. That is why we can:

- Design and provide that lifting system that performs exactly what the customer needs.

- The machine adapts to the customer’s working method and not the other way around

- The product is known for perfection, which translates into the following points:

-

- Increased efficiency in scheduling revisions

- Greater immediacy during training and transfer of knowledge of use to the client.

- Fast and immediate resolution of problems and/or breakdowns

Experts in all types of lifting tongs

You can see the tongs of this article in the following video. These models are engineered to lift and handle rocks boulders with precision and ease.

You may be interested in: Lifting tongs design

Other designs of rock lifts

Take a look at some of the other lifting tongs projects we have installed around the world:

-

TUNNEL CONCRETE SEGMENT TONG

Airpes keeps working hard to offer the safest way to work in the most delicate and precise handling and weighing…TUNNEL CONCRETE SEGMENT TONGSeptember 22, 2020

-

MESH NIPPERS

Find out more about Airpes’ Mesh Nippers, our best tool to ensure a perfect and safe lifting for your wire…MESH NIPPERSSeptember 22, 2020

Requested by Airpes’ customer Becker Stahl-Service to manufacture 2 units of fully automatic Packet-Tongs, up to SWL 7,5t.

Crosby Airpes can fulfill your project needs

At Crosby Airpes, we work hard to find the best solution to your needs at the most reasonable price. We design, manufacture, and test the handling or weighing system that best fits your company, especially if it works with rocks or other heavy materials. In the items that we made, we considered all the factors to ensure safety and improve the process’s efficiency.

FAQS about our rock grabber attachment

What type of rocks can a rock claw lift?

Our rocklift can lift various types of rocks, including large, irregularly shaped stones like granite, marble, and limestone. It’s designed for heavy-duty applications in industries such as construction and quarrying, handling stones of different shapes and sizes efficiently.

What is the difference between a rock lifter and a rock grabber tool?

A rock lifter generally refers to devices that lift stones using gripping mechanisms, while a rock grabber tool typically features adjustable claws or arms to grab and securely hold the rocks during lifting.

How do rock lifting tools adjust to different rock sizes?

Rock lifting tools, like rock lifting tongs and rock grabber tools, usually feature adjustable arms or claws. These can be widened or narrowed to securely grip rocks of varying sizes and shapes, ensuring stability and safety during lifting.

How does a rock grabber tool ensure safety in construction projects?

A rock grabber tool ensures safety through its secure gripping mechanism, adjustable arms, and safety locks that prevent accidental releases. It often includes remote operation, which allows precise control, reducing the risk of accidents in construction projects.

Can rock tongs be used in extreme weather conditions?

Yes, rock lifting tongs are designed for durability and can be used in extreme weather conditions. Many rock grabber tools are built with reinforced materials to withstand outdoor environments, including harsh temperatures, rain, and wind, ensuring reliable performance even in tough climates.