LIFTING BEAM

Engineered lifting beams for industrial environments

At Crosby Airpes, we design lifting beams that meet the highest standards of safety, efficiency, and precision. Developed to support a wide range of material handling challenges, our lifting beams adapt to complex lifting environments, from wind turbine installations to steel mill operations.

Every lifting beam is designed with your needs in mind: modular, reliable, easy to maintain, and produced for real-world heavy-duty applications. Whether your priority is headroom, load stability, or special rigging configurations, Crosby Airpes has the skills and capacity to develop a tailored and optimal solution for your lifting operation.

Available lifting beam models:

- Fixed lifting beams

- Adjustable lifting beams

- Spreader beams

- H lifting beams

- Lifting beams with moving center of gravity

- Hydraulic-powered lifting beams

- Lifting beams with leveling systems

- Motorized rotating lifting beams

Each crane lifting beam we deliver is manufactured under certified quality systems (TÜV, CE, ISO 9001) and engineered to solve lifting challenges safely and efficiently.

What is a Lifting Beam?

A lifting beam is a robust metal structure used to distribute the load’s weight evenly, improving lifting stability and safety. It is connected to a crane hoist using rigging systems such as chains, slings, and shackles. Lifting beams are commonly used to handle unbalanced loads or uniquely shaped objects that cannot be lifted with a standard hoist system.

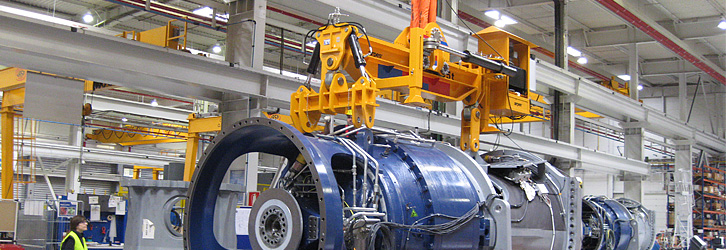

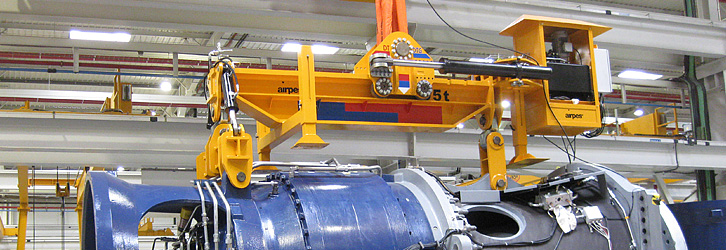

They are widely used in heavy-duty lifting operations across industries such as aeronautics, steel mills, and wind energy.

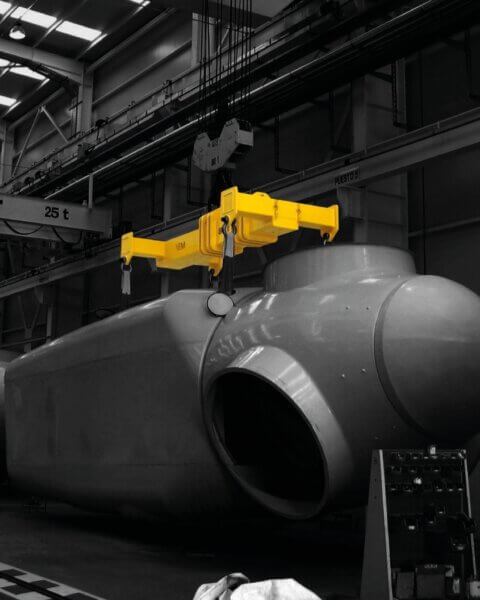

On-demand solution: drivetrain hydraulic lifting beam

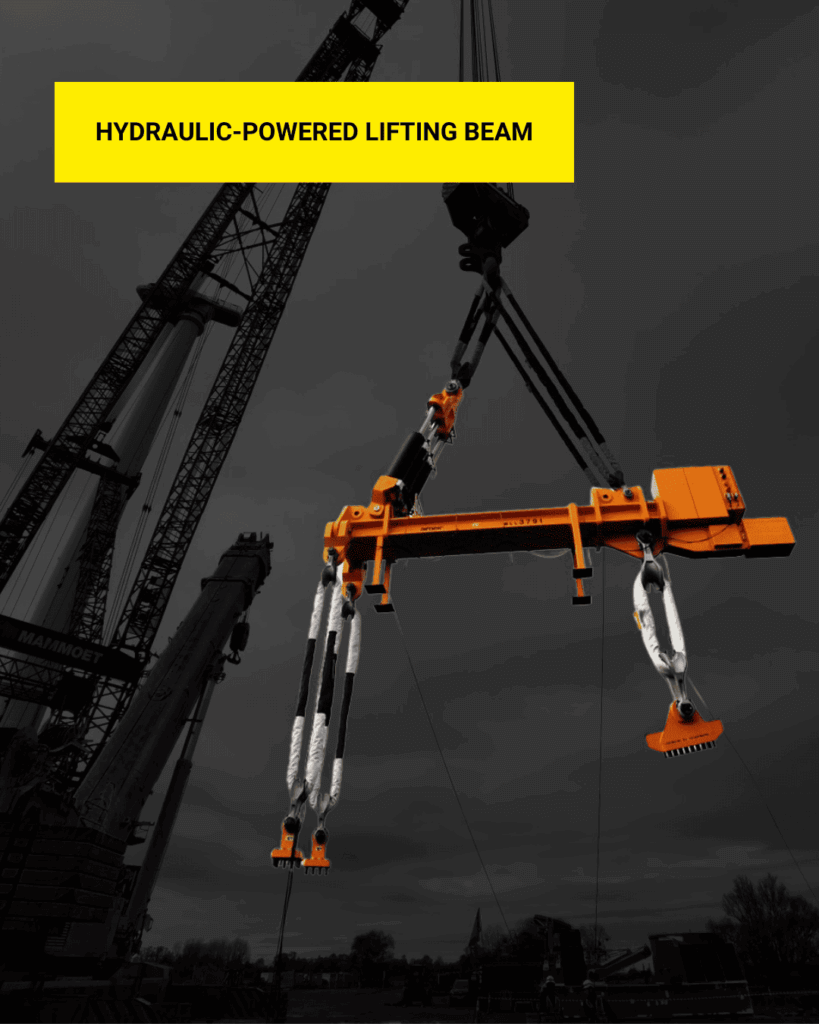

We specialize in tailor-made lifting solutions—designed from the ground up to solve real, complex challenges. One of our latest custom developments is a hydraulic lifting beam engineered specifically for drivetrain handling in extreme conditions.

Designed to operate both indoors and outdoors, and within a wide temperature range of -30ºC to +45ºC, this 95 Tm beam features a central lifting point and a precise tilting system: from 0º to -7º on the horizontal axis and ±1º on the transversal axis. It’s built to handle the drivetrain with or without its generator and transport frame, ensuring total stability and control in any configuration.

The result? A fully adaptable lifting system that improves safety, saves time, and integrates seamlessly into our client’s industrial workflow.

Why use a lifting beam in industrial operations?

Lifting beams are critical for industries where loads are large, unbalanced, or delicate. But beyond just lifting, our solutions offer strategic operational advantages:

For sectors like wind energy, steel, and aerospace, where the margin of error is zero, we deliver lifting systems that make a difference.

Types of Lifting Beams

Fixed Lifting Beams

Designed for consistent and repetitive lifts, fixed beams offer dependable performance with low maintenance. Ideal when the center of gravity is known and consistent.

Adjustable Lifting Beams

Gain operational flexibility by repositioning hook points and adjusting to varying load sizes. A smart choice for production lines, warehousing, and logistics hubs.

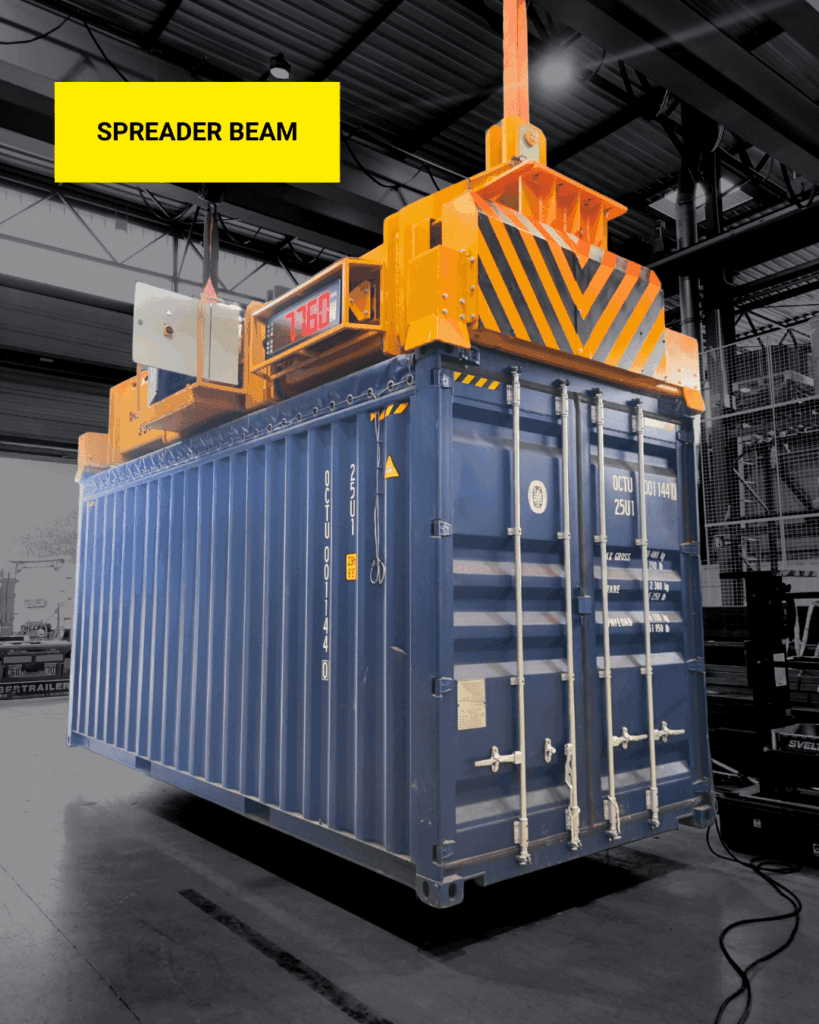

Spreader Beams

These distribute forces into compression, increasing stability for long or delicate loads. Used when additional rigging space is available and load integrity is paramount.

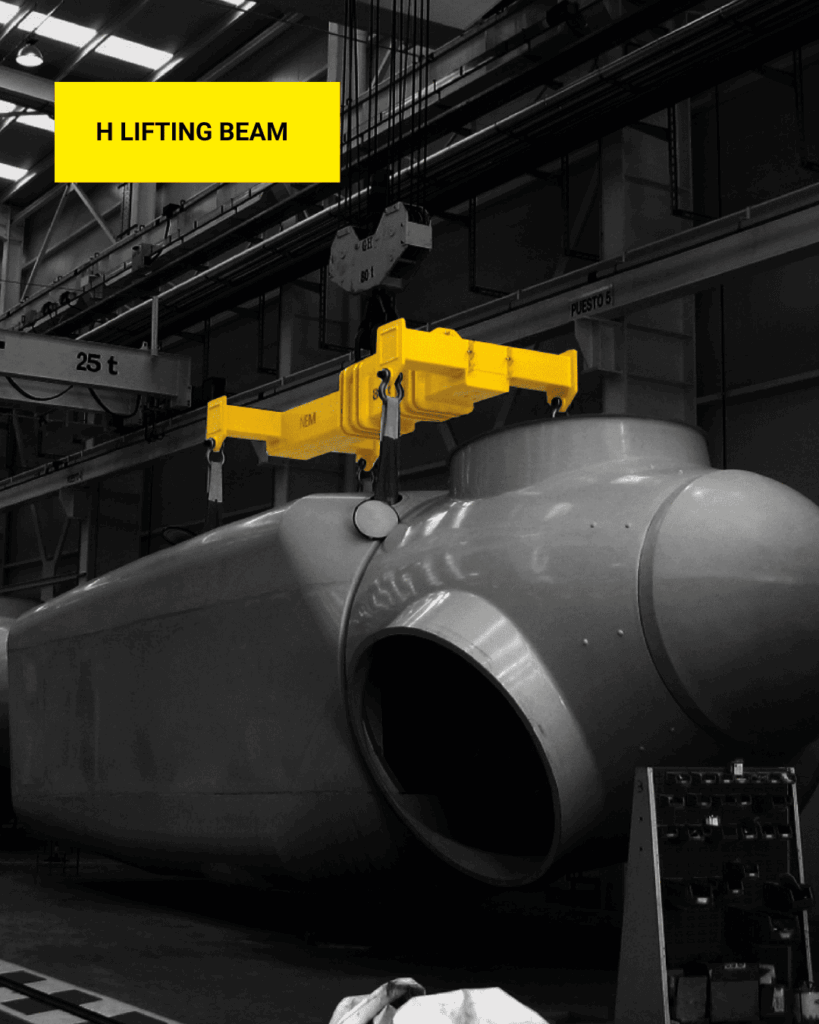

H Lifting Beams

When you’re lifting wide, oversized loads, the H beam’s four-point distribution ensures better balance. Widely used in steel and aeronautical sectors.

Lifting Beams with Moving Center of Gravity

Dynamic and adaptable, these beams allow real-time balancing of uneven or shifting loads. Reduce the risk of tilt or load drift.

Hydraulic-Powered Lifting Beams

For automated lifting tasks that require real-time adjustments and power. Perfect for high-frequency, high-load operations.

Lifting Beams with Leveling Systems

Guarantee a horizontal position during the lift, essential for sensitive components and fragile structures.

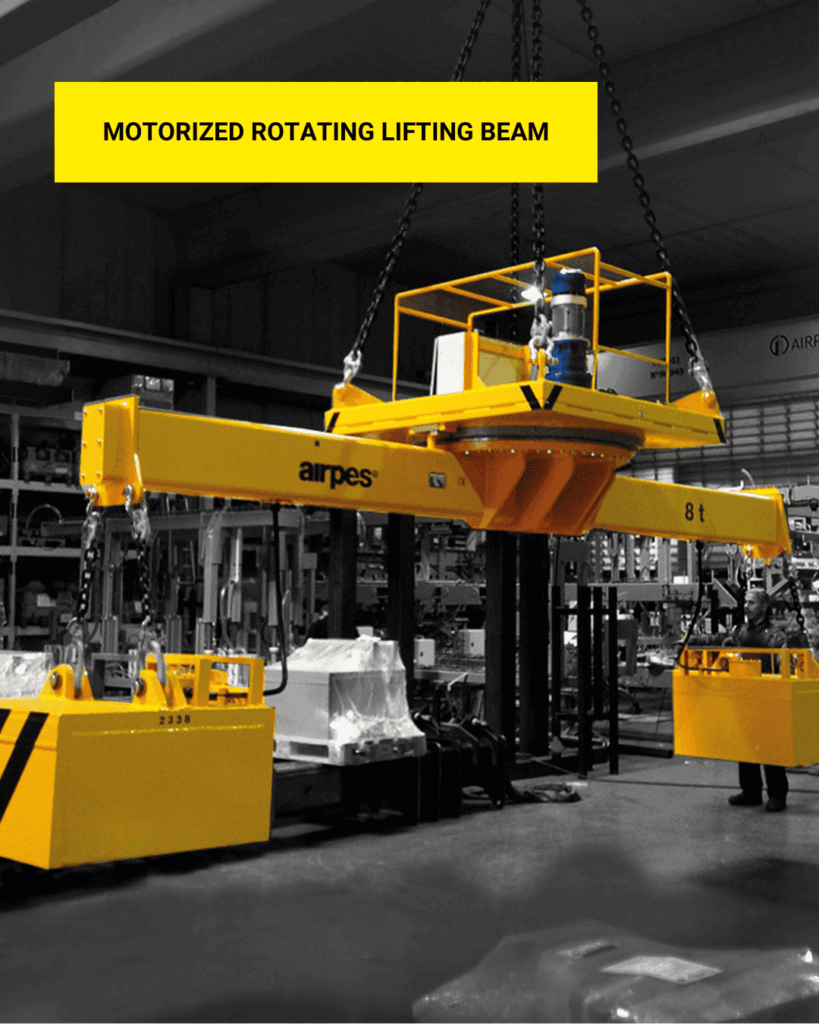

Motorized Rotating Lifting Beams

Full 360° control from the ground. Reduce manual intervention and optimize precision during placement or assembly.

-

LIFTING BEAM

Engineered lifting beams for industrial environments At Crosby Airpes, we design lifting beams that meet the highest standards of safety,…LIFTING BEAMSeptember 22, 2020 -

RAIL LIFTING BEAM

Our rail spreader beam is a solution designed by Airpes to lift and handle train rails in an easy and…RAIL LIFTING BEAMSeptember 22, 2020 -

SPREADER BEAM

Airpes spreader beams are the perfect solution if you need a lifting beam and you don't have a low headroom…SPREADER BEAMSeptember 22, 2020 -

TURN LIFTING BEAM

Airpes designed a 20t. turn lifting beam with electro-hydraulic capacity, specially designed for air transportation. A lifting beam is a…TURN LIFTING BEAMSeptember 22, 2020

Lifting beam vs spreader beam

A lifting beam suspends the load from a single top rigging point, which subjects the beam to bending moments. This makes it compact and well-suited for headroom-restricted applications, but it demands higher-strength materials and a more robust cross-section to withstand flexural stress.

A spreader beam uses multiple top rigging points, transforming bending loads into axial compression. This structural efficiency allows for lighter construction and superior load stability, though it requires additional vertical clearance.

Need help selecting the right solution? We’ll analyze your load characteristics, crane configuration, and spatial constraints to recommend the optimal beam design for your application

Comparison table

| Type | Ideal For | Main Benefit | Limitations |

| Fixed Lifting Beam | Repetitive, consistent loads | Simplicity and durability | Limited flexibility |

| Adjustable Lifting Beam | Variable load shapes | Adaptable to changing needs | Requires manual adjustments |

| Spreader Beam | Long/heavy loads | Excellent weight distribution | Needs more rigging space |

| H Lifting Beam | Oversized or irregular items | Four-point stability | More complex to fabricate |

| Hydraulic Lifting Beam | High-volume industrial lifts | Automated adjustments | Requires hydraulic systems |

| Motorized Rotating Beam | Loads needing orientation mid-air | Remote 360° positioning | Higher investment |

When precision and stability matter, our crane lifting beams offer reliable performance across various industrial applications.

Why choose Crosby Airpes?

- Certified excellence

CE, TÜV, and ISO 9001-certified equipment.

- Tailored engineering

Each beam is custom-made for your exact needs.

- Proven industry excellence

Trusted by aerospace, renewable energy, and steel leaders.

- Global support

From design to installation and servicing.

- Integrated solutions

Works with hoists, electric chains, PLCs, and custom automation.

Clients around the world trust us because we deliver equipment that performs when it matters most.

Looking for a lifting beam engineered for your specific operation?

We design custom crane lifting beams that match your load profile, crane capacity, and operational constraints. Whether you need a compact lifting beam for tight headroom or a heavy-duty spreader configuration for complex loads, our engineering team will specify the right solution.

Explore our complete range of below-the-hook lifting solutions or contact us to discuss your lifting requirements.

A lifting beam connects at a single point, making it perfect for low-clearance operations. It’s simple, compact, and ideal for vertical lifting. A spreader beam, in contrast, uses multiple points to distribute weight, offering more balance and less stress on the load. Use lifting beams when space is tight and spreader beams when stability is key.

You can combine lifting beams with:

- Eye bolts

- Lifting clamps

- Pallet lifters

- Ratchet lever hoists

- Electric chain hoists

These accessories allow the beam to adapt to various industries like shipping, manufacturing, and logistics.

We use high-strength steel alloys, selected for their durability, resistance to bending, and ability to withstand extreme load conditions. All materials are compliant with international lifting standards, and every beam is tested under load.

Frequent inspections help prevent equipment failure, prolong the beam’s life, and ensure legal compliance. We recommend scheduled checks to detect stress fractures, corrosion, or wear.

- Wind Energy: for lifting blades, hubs, and nacelles

- Steel Mills: coils, plates, and billets

- Aerospace: sensitive components and large parts

- Ports & Logistics: container handling and machinery

Yes. Customization includes:

- Manual or motorized adjustment

- Hydraulic systems

- Load-monitoring integration

- Special coatings for outdoor or corrosive environments

Let us design the right tool for your operation.

A crane lifting beam is specifically designed for integration with overhead or gantry cranes, offering enhanced lifting control and load security.