LIFTING ELECTRO MAGNET

We have the most interesting products in the industrial electromagnet field because we are in charge of the whole lifting electromagnet design, but also of its whole production and delivery. See an example of how we work clicking in Telescopic Permanent-Electro Magnetic System.

A magnet will allow to lift any material made out of metal that can be attracted to a magnetic field. They are easy to maintain and easy to work.

Why don’t you request us a quote? We have decades of experience in designing the best lifting devices for industries all over the world. Discover our outstanding products, the best customer service and the most competitive prices. We lift your future.

Lifting electromagnet features

Electromagnets are also designed to work in extreme conditions like hot or really high-temperature rooms, dust, heavy-duty environments, small rooms, or high service factor plants.

Benefits

Scalable and reliable

Lifting electromagnets are easy to operate, can be used for handling situations in a factories involving steel and magnetic metals. We have installed electromagnetic lifts all over the world, in different shapes and for many different industries. Click here to check out some of our best electromagnet lifting systems we have installed.

Airpes manufactures all kind of electromagnets for all kind of applications. The only limits when designing lifting magnets are the customer’ crane and hoist capacities. We can design:

- Round shaped lifting magnets

- Square shaped lifting magnets

- Personalized surface (flat, round…), magnetic field, lifting capacity…

- We fabricate in all measures to increase the options for our customers

Different configurations

Magnets have a cast case with aluminum or copper coil. As well they can be built with a standard field, deep-field or extra deep field depending on the application.

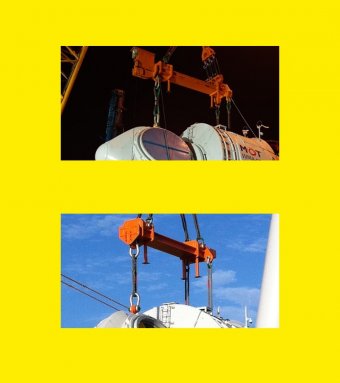

Our electro magnets can be used individually or in series of multiple magnets, with different suspension systems and weight lifting capacity. Airpes provides an integral solution through the use of lifting beams from where to hang all the required magnets.

Optional services and parts

Optional features can be added to every lifting magnet installation to make the most of your material handling magnet. For example:

- Telescopic opening/closing

- Special suspensions

- Fixed welded hooks to increase system’s versatility

- Protection pads

- Loose cable control

- Collision control

- Stock in/out control on every lift

- Radio control or device information

- Battery powered (power failure safety system)

- Integrated rotation

Own design and engineering

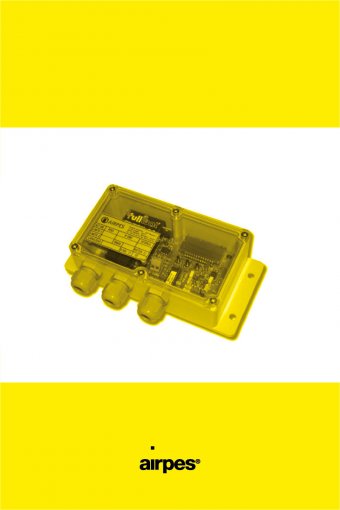

We design, build, and supply the complete system: the solenoid, the power supply (cable reel as optional) and every wire of the electrical Control Box and circuit. This box is manufactured and controlled by our electrical engineering department who ensures the system complies with voltage, electrical resistance, and electrical safety standards. Airpes’ electric engineers are also in charge of supplying support batteries to prevent the accidental release of the load in case of power supply failure. We give at least 20 extra minutes of power supply by the battery. Battery for the lifting electromagnet can be supplied in Pb or Ni/Cd as optional.

Material handling lifting magnet project

Check out this article where we describe a lifting magnet installation in central America

Sectors

Electro magnets can be as powerful as required and used for nearly every handling situation in a factory involving steel plates, profiles, scrap, handling tubings, rebars, bars stock, plates, coiled strips, structural shapes, castings, forgings, and bundles. Any metal material that can be magnetized can be handled with electromagnetic lifts.