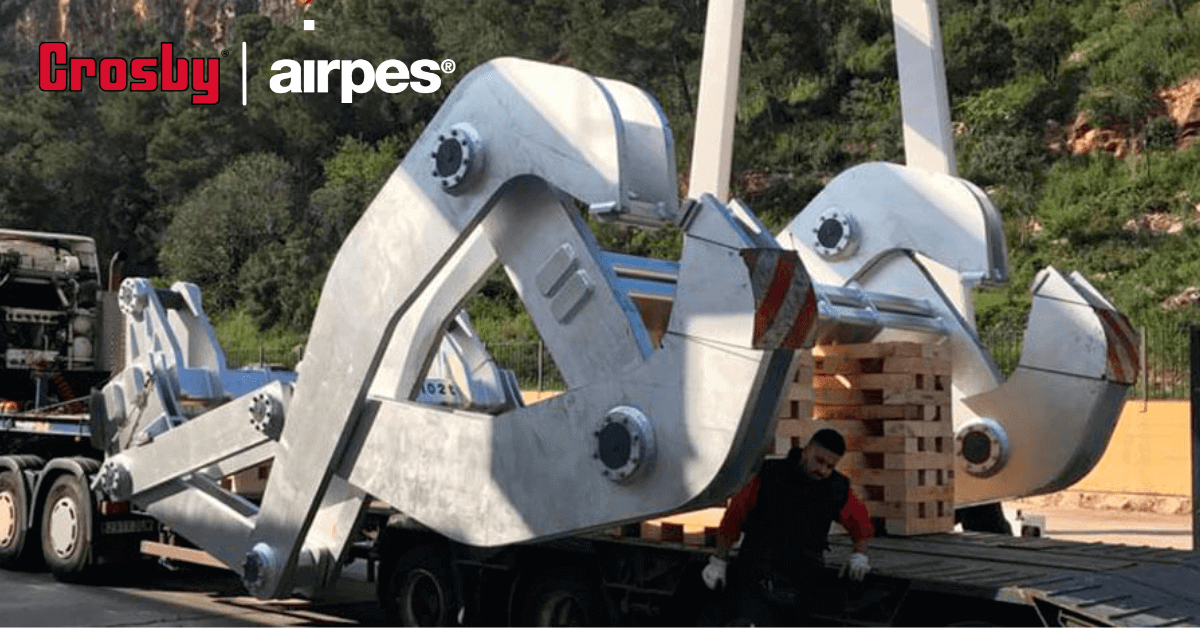

C-Hooks are a great option if you work with wire or rope coils and need heavy-duty machinery to handle them.

Crosby Airpes is a world leader in the design of C-Hooks, other lifting hooks, and industrial lifting systems.

Discover what a C-Hook is used for and the types of metal coils that a C-Hook can handle quickly and effectively.

What is a C-Hook used for?

The most frequent use of a C-Hook is the lifting and handling metal coils or rolls, such as steel coils. It could be used, for example, for warehouse management in companies in the metallurgical industry.

Coils are how metallic intermediate materials companies used to sell large quantities of products. A coil is a convenient format that is easy to handle and manage (in terms of weighing, quantity control, etc.) for companies that will handle and create final products with a metallic base.

Three types of metal coils

Customers who contact us to acquire a C-Hook usually have to manipulate three main types of metal coils. Let’s see what they are.

Metal wire reels

These are coils of cable, wire, and in general, any metallic wiring produced in the form of a wire. Buyers will use this type of material to make products such as metal fences, safety nets, etc.

Metal strip coils

Metal strip coils are used for very thin sheets of rolled metal to produce many products. Metal strips can’t be folded and wound. They are made continuously and rolled on a coil.

Electric cable rolls

Electric cables are not a direct product of the metallurgical industry. They would only be so in the case of thick high voltage cables that do not have an insulating coating. Although for their industrial production and sale, they are also wound in coils for better handling.

Other types of uses for the C-Hook

C-Hooks are not only suitable for lifting steel or metal coils. They can also be used for various applications and adapted to other sectors. Some examples would be:

Handling of pipe sections

In the case of companies that produce large metal pipes, a C-Hook allows each section of pipe made to be handled comfortably and safely.

Non-metallic coils

A C-Hook can handle virtually any type of coil of any material, although adaptations to the design will have to be made in some cases. For example, a C-Hook can handle different types of coils like:

- Fiber or rope cabling

- Paper reels in the paper industry

Advantages of a C-Hook compared to other systems

C-Hooks have two competitive advantages over other types of lifting systems. Crosby Airpes recommends a C-Hook for the following reasons:

- They are easy to maneuver as the grip of the coil is made only by approximation movements without the need to operate other gripper systems simultaneously, such as clamps, activation, and deactivation of electromagnets, etc.

- Less maintenance since there are no moving parts: a c-hook is a solid metal block built to support the loads the customer requests mechanically.

Crosby Airpes is your on-demand handling solutions supplier

Crosby Airpes designs C-Hooks to meet customers’ specific coil handling requirements. We manufacture these hook lifting products according to the FEM Standards. We know you keep an eye on quality, so Crosby Airpes, in its concern about safety in the workplace and understanding different loads and handling operations, has based the standard safety factor of 4:1 on its entire line of products.

If you need a coil lifting hook or another coil handling device, we’ll help you.