The size of and height of wind turbines are increasing every year. Installing a wind turbine blade is an engineering challenge that Crosby Airpes can successfully overcome thanks to our proven experience and deep technical knowledge.

Wind turbine blade: characteristics

A wind turbine blade is a key element of a wind turbine, as the nacelle and the gearbox. It harnesses wind’s kinetic energy and transforms it into mechanical energy for electricity production.

Usually, a blade is about 35 tons, around a 17,5% of the wind mill. The largest onshore wind turbine blades can reach up to 70 tons, while offshore blades are even heavier due to greater efficiency demands.

These blades are elongated and shaped aerodynamically, akin to airplane or propeller blades. They are mounted on a hub that links to the wind turbine’s main shaft.

Wind turbine blades are made from a combination of materials including fiberglass, carbon fiber, epoxy resin, polyester resin, core materials like balsa wood or foam, protective coatings, and small metallic components. This complex composition makes them delicate and requires precise tools for safe handling and installation.

Both offshore and onshore wind turbines generates electricity worlwide. A correct installation and ongoing maintenance are essential to maximize the efficiency, reliability, and lifespan of wind turbines.

Installation of a wind turbine blade

Figuring out the center of gravity for wind turbine blades at significant heights is tricky and requires specialized the right tools.

Installing wind turbine blades is challenging due to their large size and weight, the demand for precision alignment, and the elevated heights where the work takes place. Unfavorable weather conditions, particularly in offshore environments, further complicate the process.

Transporting these large blades to often remote sites adds logistical difficulties. The process requires technical electrical and mechanical work, demanding highly skilled technicians. Ensuring worker safety and minimizing environmental impact are also critical considerations in these installations.

In fact, as highlighted in the DNV-ST-0054 international standard, following strict guidelines for wind turbine transport and installation is crucial to ensure not only structural integrity but also operational safety. These best practices are essential when handling such large and delicate components under challenging conditions.

Ensuring worker safety, minimizing environmental impact, and preventing damage to the blades are also critical considerations during installation.

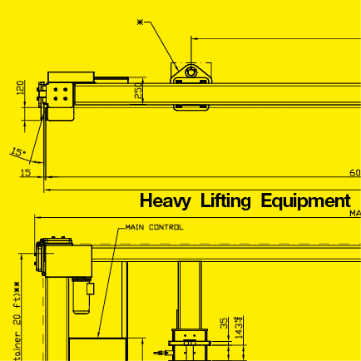

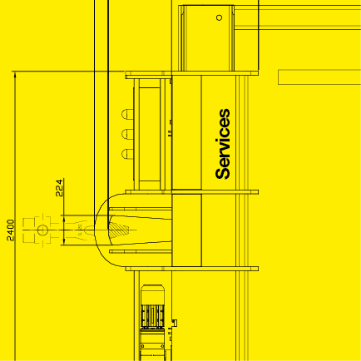

Crosby Airpes provides engineered lifting solutions, including the robust Yoke Blade Clamps, equipped with an advanced safety kit that makes this task safer, more stable, and highly reliable. These blades are important for turning wind into electricity and require expert teams for installation and ongoing maintenance.

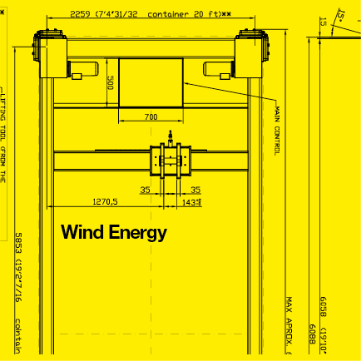

Yoke Blade Clamps by Crosby Airpes

Using Crosby Airpes’ Yoke Blade Clamps significantly simplifies the installation process by enhancing safety, reducing the risk of blade damage, and improving operational efficiency.

The kit includes:

- Cameras for real-time monitoring.

- A telemeter for precise distance measurements.

- An integrated safety system that continuously checks clamp integrity

This advanced setup also supports maintenance tasks, like accurately determining the blade’s center of gravity at height, improving stability, and preventing alignment issues.

Know more here: “Integral solution for the installation and maintenance of wind turbine blades”

Crosby Airpes is a leading provider of specialized equipment for installing, transporting, and maintaining both onshore and offshore wind turbine blades.