Lifting hooks are pivotal tools in the realm of industrial lifting and material handling, seamlessly integrating strength, precision, and safety into daily operations across various sectors.

From construction sites and manufacturing plants to docks and warehouses, lifting hooks play a crucial role in ensuring the smooth execution of tasks that involve lifting and moving goods.

Every lifting hook is meticulously designed to fulfill particular needs, guaranteeing safety, effectiveness, and dependability in tasks related to material handling. Selecting the right lifting hooks is contingent upon the intended use, characteristics of the material, and the conditions under which they will operate

Benefits of all types of lifting hooks

- Improved Load Management: Specialized hooks enhance the precision and security of load handling, reducing movement damage and improving overall material handling efficiency.

- Durability and Longevity: Constructed from tough materials like alloy steel, all types of lifting hooks offer resilience against wear and harsh conditions, ensuring a prolonged lifespan and lower replacement frequency.

- Versatility and Adaptability: Their wide range of designs and capacities make lifting hooks suitable for various applications, allowing for their use in multiple industries with different load types.

- Operational Efficiency: By facilitating quicker load attachment, lifting hooks streamline lifting tasks, leading to significant time and labor savings and accelerated project timelines.

- Safety Enhancement: Equipped with safety mechanisms such as latches, lifting hooks minimize the risk of load disengagement, enhancing site safety and reducing accident risks.

Principal types of lifting tongs

Lifting hooks come in a variety of designs, each tailored to specific applications and load types.

- Eye Hooks: Featuring a simple looped end, eye hooks are designed to be attached to slings and chains by threading. Their simplicity makes them versatile for many lifting applications.

- Swivel Hooks: These hooks can rotate 360 degrees, making them ideal for applications where the load may need to be turned or rotated during lifting. The swivel feature helps prevent twisting of the lifting cable or chain.

- Self-Locking Hooks: Designed with a safety mechanism that automatically locks when a load is applied, self-locking hooks increase safety by preventing accidental release of the load.

- Foundry Hooks: With a larger opening than standard hooks, foundry hooks are designed for lifting heavy loads with lifting slings. They are commonly used in foundries and steel mills for moving large castings and other heavy materials.

- Sling Hooks: Often used at the end of a chain or wire rope sling, these hooks have a wider throat opening to easily attach to loads. Some sling hooks come with a latch for added load security.

- C-hooks: Specialized lifting tools designed for handling and transporting coils, rolls, and other cylindrical objects.

Versatile, secure and efficient: C-hook

C-hooks are specialized lifting tools designed for handling and transporting coils, rolls, and other cylindrical objects.

Their name comes from their distinctive “C” shape, which allows them to cradle the load securely during lifting and movement.

C-hooks are particularly useful in industries such as steel and aluminum manufacturing, paper mills, and other sectors where coil handling is a regular task.

Benefits of Crosby Airpes C-hooks

C-hooks are ingeniously designed with a curved shape to securely cradle coils, minimizing material damage during handling thanks to their match to the coil’s radius. Available in a wide array of sizes and capacities, these hooks can lift anything from light to several-ton coils, catering to diverse industrial needs. Constructed from high-strength steel or similar robust materials,

C-hooks endure the demands of industrial use without bending or breaking. Equipped with safety enhancements like latches or locking mechanisms, they ensure a secure and balanced lift, mitigating accident and injury risks. They are versatile, operable manually or with machinery such as overhead cranes and forklifts, and can be customized in size, functionality, and protection to meet specific industry requirements, including adjustable widths and protective linings for delicate materials.

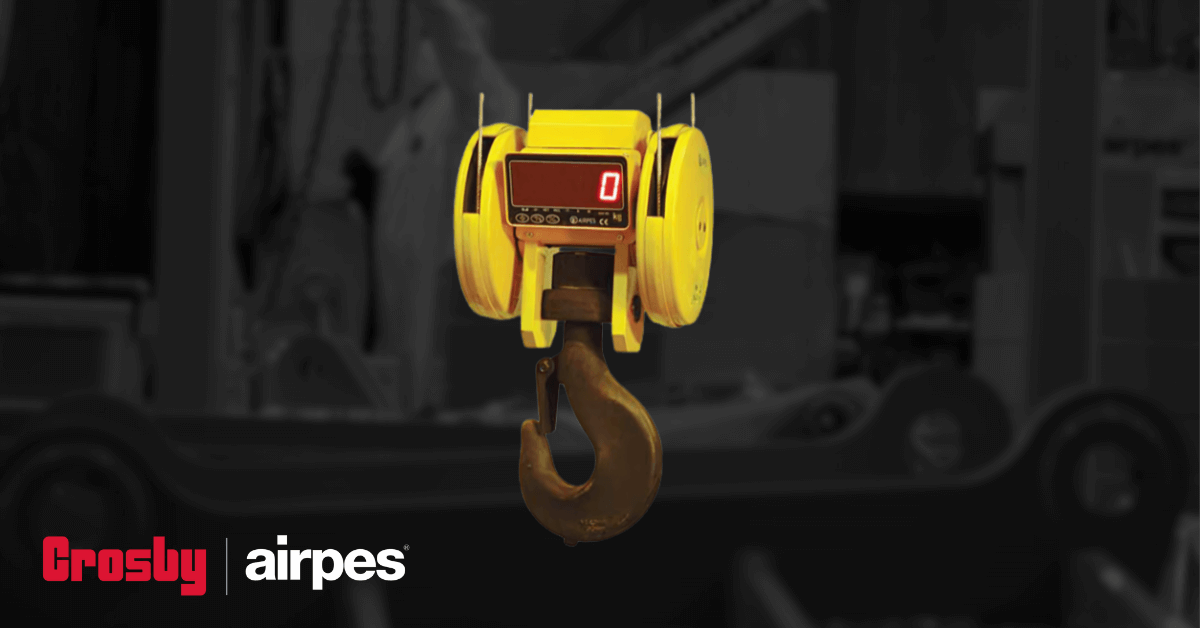

About weighing hooks, a type of lifting hooks with an extra

If you want to know more about this solutions, you can read it here.

Weighing hooks are crucial tools for measuring the weight of heavy items, designed to be attached to lifting equipment like cranes and hoists. These devices provide precise weight measurements, essential for managing inventory, reducing shipping costs, and adhering to safety standards.

They offer the convenience of weighing items in mid-air, which enhances safety by eliminating the need to place heavy items on ground scales, and improves efficiency by integrating weight measurement directly into the transport process.

Crosby Airpes, specializing in crane scales, offers models that combine weighing and lifting, customizable with additional functions to meet specific requirements, ensuring adaptability across many industries:

Crosby Airpes help you with your specific type of lifting hooks

At Crosby Airpes, we are specialists in lifting equipment, your equipment.

Each type of our lifting hooks can be customized to match with your needs and solve the problems that can appear.

Do you have specific needs? We solve it with our on-demand solutions.