In the bustling world of manufacturing, construction, and various industrial sectors, the efficient movement of goods and materials using modern material lifting equipment is crucial for achieving a fast and seamless flow of materials and products.

Related post: Tips and what to think about before buying lifting equipment

In this article, we will give you 4 advantages that material lifting equipment brings to businesses across different industries and a short list of specific designs you can install on a crane or lifting device.

Do you move heavy materials? 4 reasons why you need specialized material lifting equipment

A next-generation lifting device can help improve heavy material moving processes in a factory in an amazing way.

Let’s take a look at 4 reasons why, if you move materials within your factory, you should have the latest technology available to lift and move those materials.

1- Enhanced efficiency and productivity

Efficiency is the cornerstone of any successful business, and material lifting equipment significantly contributes to this goal.

Whether you’re in manufacturing, construction, logistics or any other industry that involves the movement of heavy materials, the use of lifting equipment can dramatically speed up the process of building and shipping materials.

Cranes and other lifting devices can handle heavy loads with ease, reducing the need for manual labor and cutting down on project completion times. This increased efficiency translates directly into improved productivity, ultimately benefiting your bottom line.

2- Improved safety standards

Safety is paramount in any workplace, and material lifting equipment is designed with safety in mind. Using cranes and other lifting devices minimizes the risks associated with manual lifting and handling of heavy objects.

This not only protects your employees from potential injuries but also mitigates the chances of damage to your valuable materials or products and complies with OSHA and other safety regulations. Additionally, modern lifting equipment often comes equipped with advanced safety features, further enhancing workplace security.

3- Versatility across industries

Material lifting equipment finds applications in various sectors, making it a versatile asset for your business.

For example:

- In the construction industry, cranes are indispensable for lifting heavy construction materials and equipment to elevated locations.

- In manufacturing, they facilitate the efficient movement of raw materials and finished products within the production facility.

- Beyond these sectors, material lifting equipment is also used in shipyards, warehouses, and tenths of places more, showcasing its adaptability and utility.

As well, the same design of crane can be easily equipped with a totally different below-the-hook system. One option could be designing a system to lift metals through magnetization for a company that needs so, or for the same crane in another company it can be installed a specific lifting beam for another totally different job.

4- Cost-effective solution in the long run

While the initial investment in material lifting equipment may seem substantial, it ultimately proves to be cost-effective in the long run. The efficiency gains, reduced labor costs, and minimized material damage translate into significant savings over time.

Additionally, these machines are built to last for at least a few decades if the maintenance cycles are done when it is supposed to, offering durability and longevity. In other words: they are a wise investment for any business that moves heavy loads and that is looking to optimize its operations.

Diverse equipment options can be installed on almost any type of crane

When it comes to material lifting equipment, you have a wide range of options in terms of specific below-the-hook system you want to install.

That allows you to select the one that best suits your specific needs no matter the type of crane you have installed in your factory. Some of the common types of equipment that can be installed in lifting devices (and that Crosby Airpes can design for you) include the following ones.

C-Hook

Ideal for lifting and transporting coils, pipes, and other cylindrical objects.

No matter how big or heavy the coil or pipe is, we can design the C-Hook you need in terms of capacity and functionality.

Lifting magnet or electromagnet

Used for handling ferrous materials such as thin steel plates, iron rebars, metal mesh and small beams.

No moving parts and a very simple design make lifting magnets a very demanded solution for iron based materials.

Lifting beam or spreader beam

Designed for lifting elongated loads or loads that need at least two fastening points, such as timber, special heavy parts or very large pipes.

The brother of the lifting beam is the spreader beam, that allows to lift heavier loads with a beam built with less material. The limitation to use a spreader beam is only the headroom available in the premises.

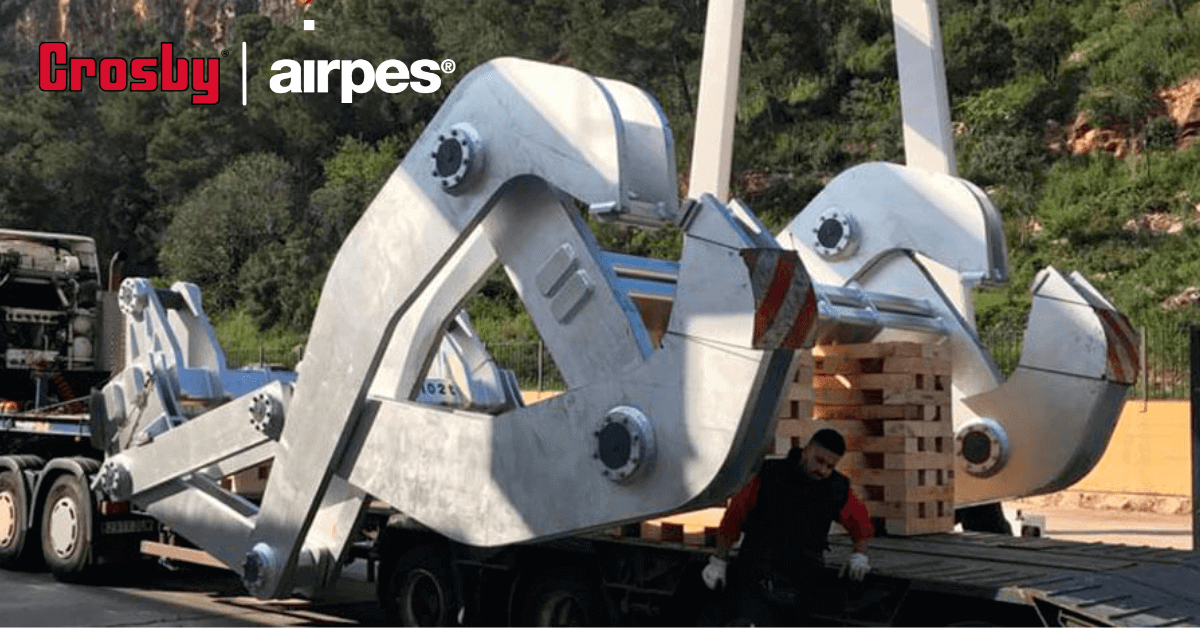

Lifting Tong

Perfect for securely gripping and moving materials with irregular shapes or materials that need a strong grip like rocks, heavy beams, timber and trees, or coils (this last one as an option for coils other than C-Hooks).

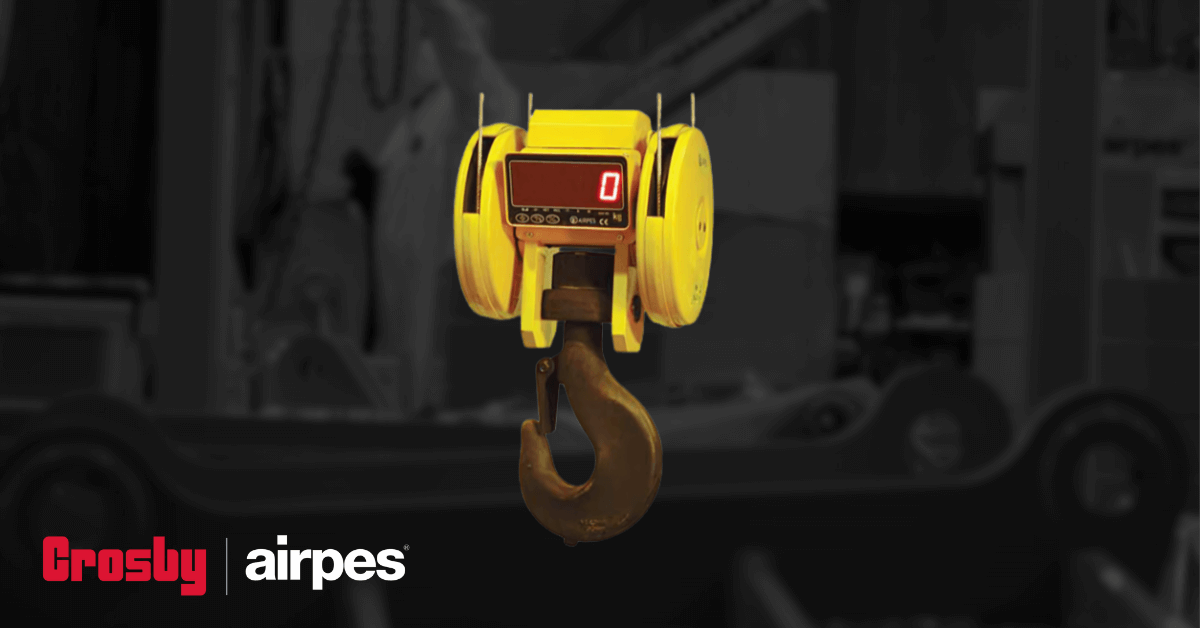

Weighing Hooks

Provides the added benefit of weighing materials while lifting and moving them, ensuring accurate measurements and saving a lot of time when it comes to measuring volume of materials or products loaded or unloaded: weigh them while you move them.

Some of our material lifting equipment solutions

Material lifting equipment is a valuable asset for businesses across various industries.

The ability of a modern lifting device to enhance efficiency, improve safety, and provide versatility makes it an indispensable tool for streamlining operations and boosting productivity if you have to move a lot of materials per day.

Whether you’re involved in construction, manufacturing, wind energy or other industrial sectors, integrating material lifting equipment into your workflow can lead to substantial benefits for your business.

Discover some of our aforementioned solutions that we can install on your actual crane or lifting device.