Blade Lifting and Rotation System for Transport

On-demand solution for VESTAS

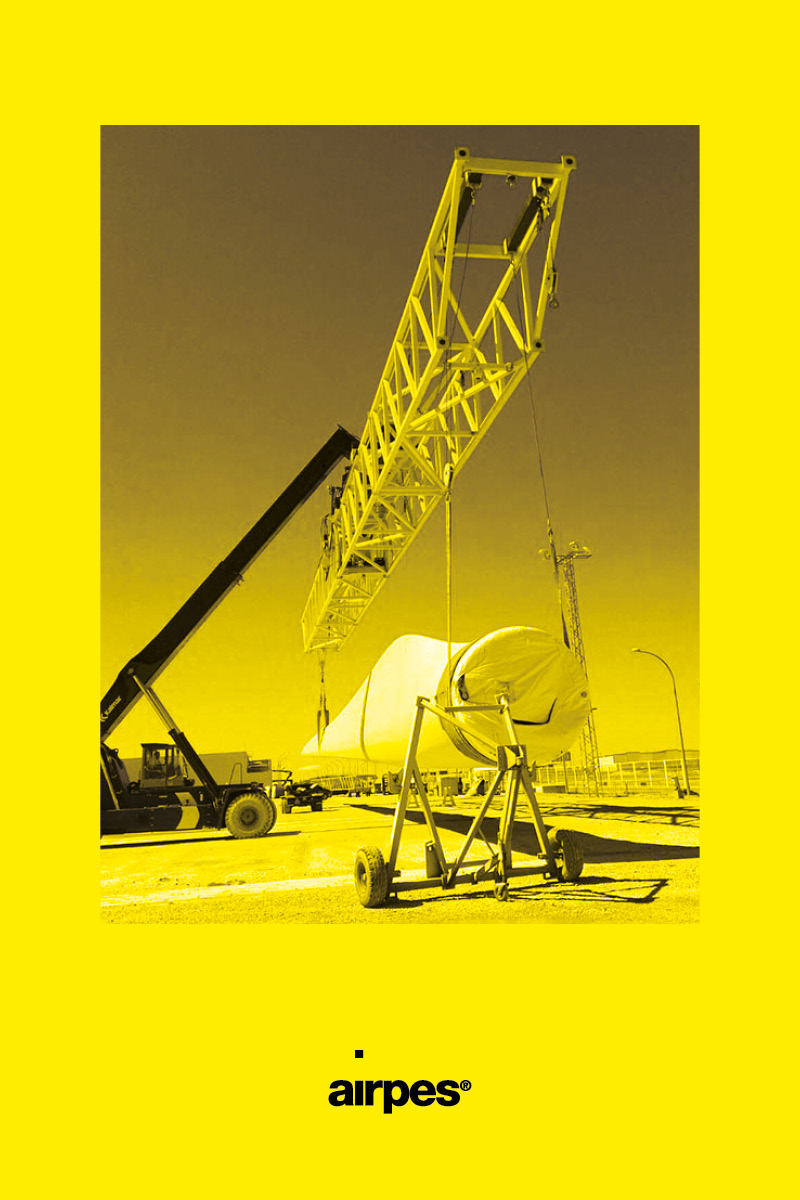

The latest on-demand solution designed by Airpes has been for the company Vestas, with the design and manufacture of a lifting system for moving wind turbine blades.

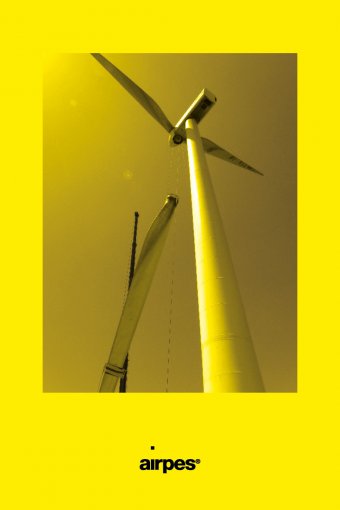

Moving wind turbine blades

Preparing the shipments of their wind turbine blades, Vestas found the need to improve productivity and a quicker and more effective, with better security, way to carry out their project.

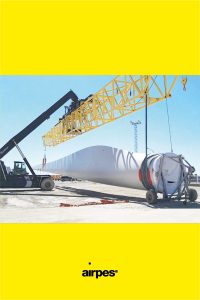

Wind turbine blades are produced in the plant of the company, but its preparation for shipment are made outside, so they had to transport them and move them safely and efficiently.

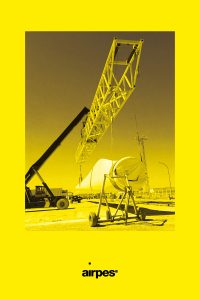

Airpes proposed the design and construction of a type lattice lifting equipment. 4 adjustable winches are responsible for lifting and turning moves while an integrated reach stacker includes an electro-hydraulic control.

Angle Control

Thanks to the electro-hydraulic control and the angle control system, we can know the blade’s angle in real-time.

Wind Load Information

Using sensors in our tool, we can know the Wind Speed and translate it to the Load that the Wind is performing in our tool with the Blade.

Signal Video Cameras

In order to ensure that the system is working properly, a wi-fi controlled video signal is feed to the operator to ensure the safety of the blade during transport.

Rotation at will

Due to the necessity of the client, the tool incorporates a Rotation system for the blade’s tilt.

Electro-Hydraulic Winch System Control

Our system is powered by a tailor-made electro-hydraulic system to control the winch, which provides control over the lifting and rotation capabilities of the tool.

Safety First

With safety as our utmost important goal, the tool ensures safety with all the detailed highlights before mentioned; cameras, angle control, load control, wind load control, and so on…