Weighing System Project for a Swiss Company

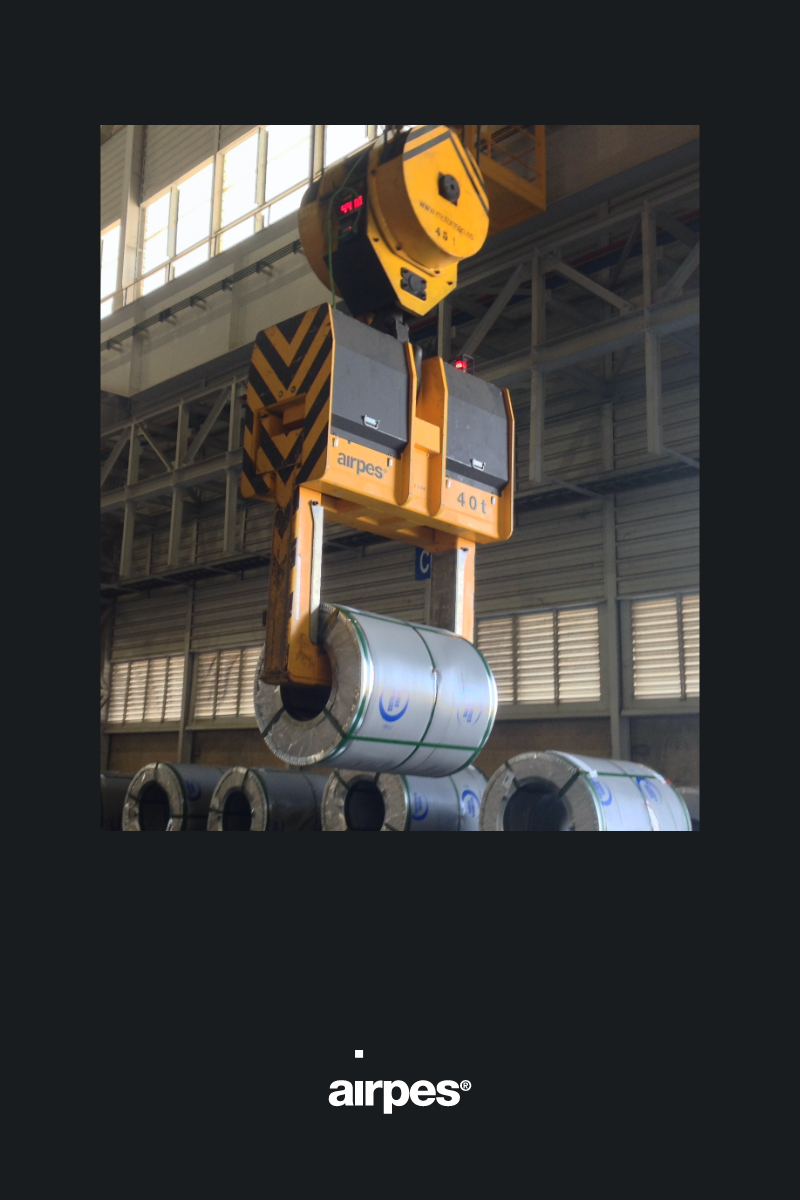

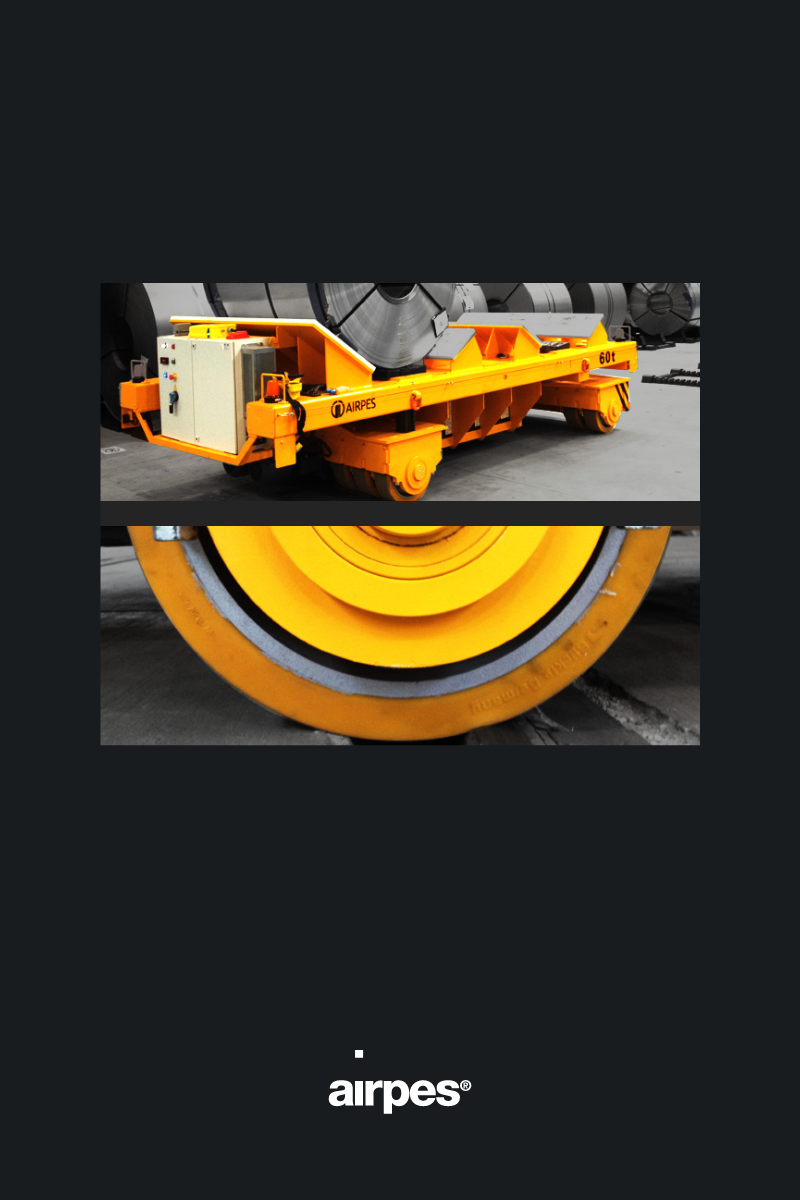

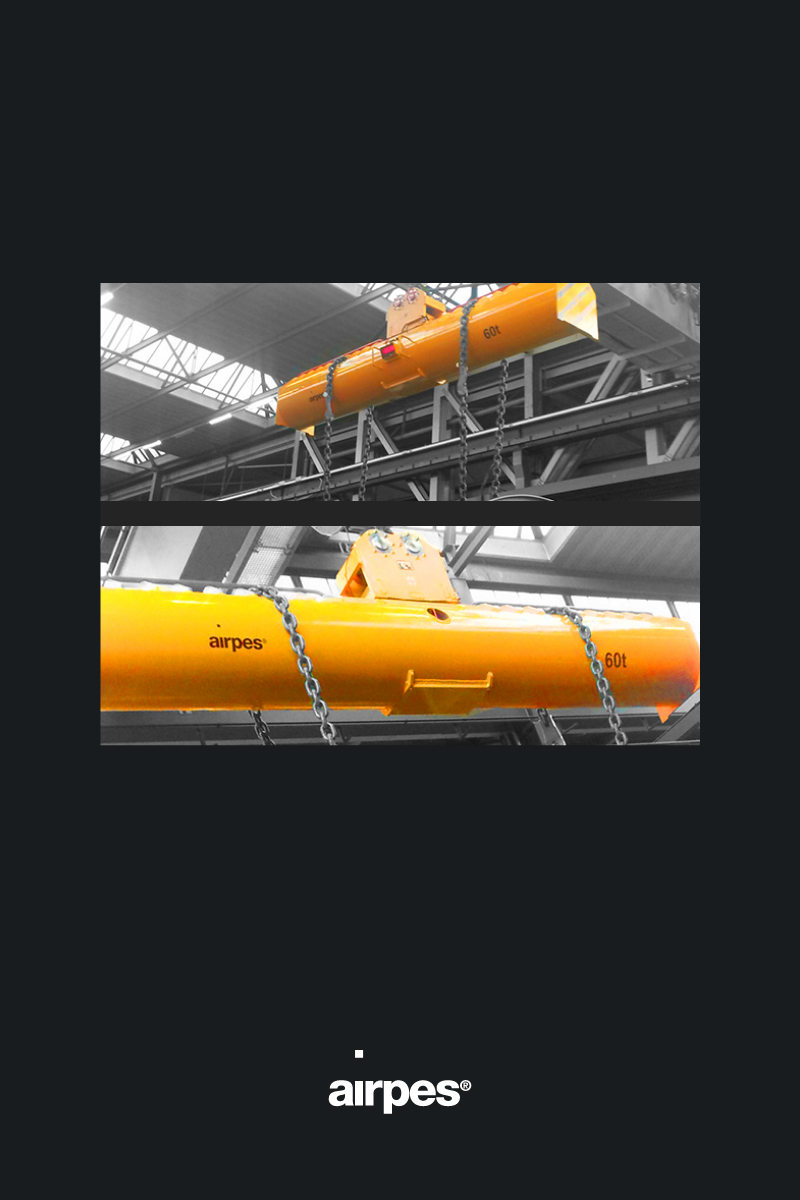

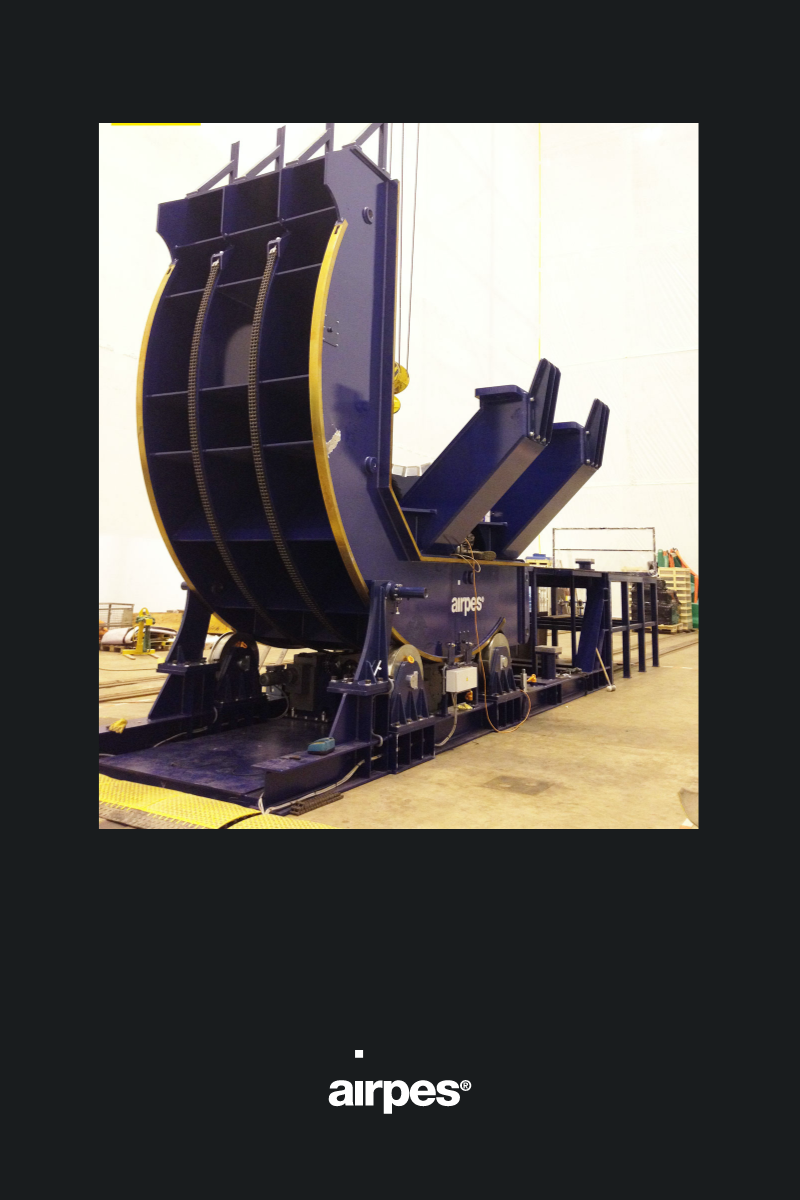

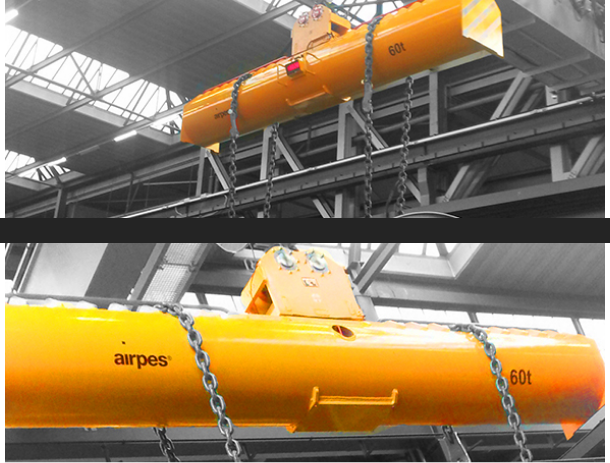

Airpes, along with its Switzerland distributor, Hausherr, delivered a 60t handling and weighing system to the Swiss company Brugg Kabel AG with 0.1% accuracy in weighing of wire coils.

Initial situation description

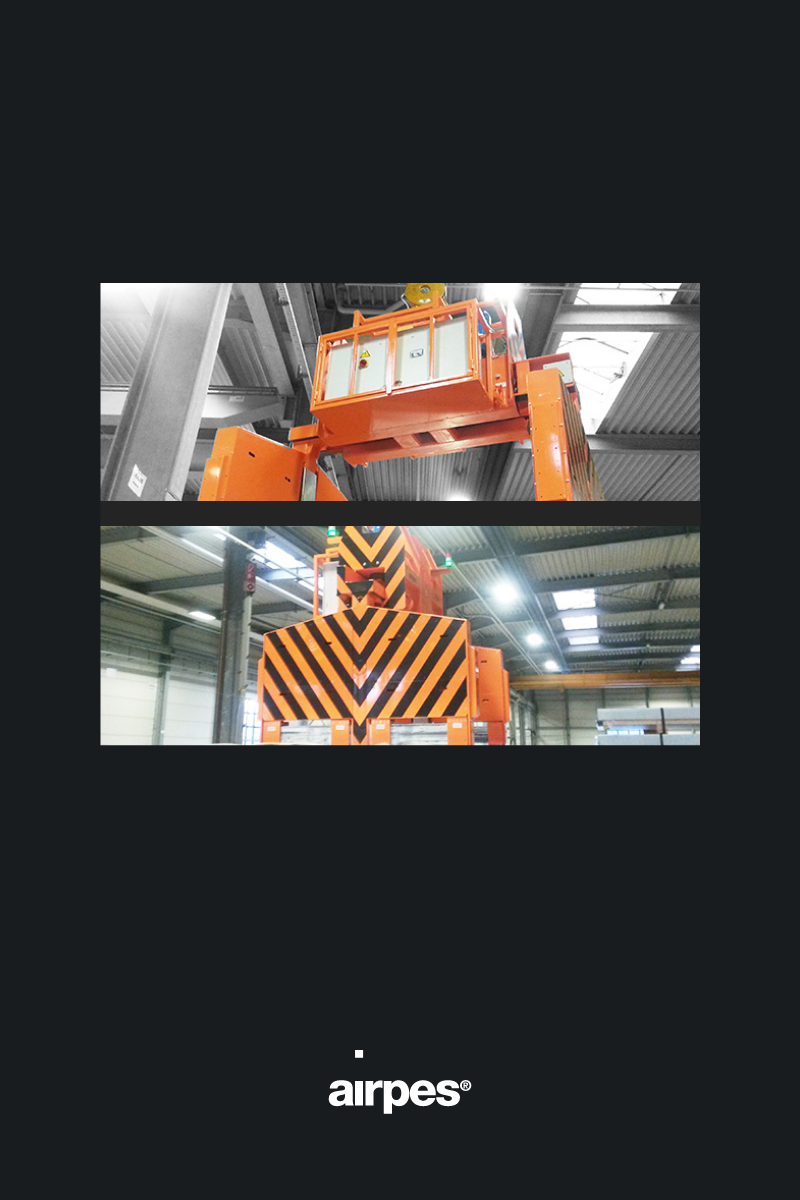

The client had an old crane with an old handling system. In the need to transport larger and heavier wire coils, a new crane and a new handling system is presented by Airpes, along with Hausherr. The old weighing system can’t weigh the wire coils because its dimensions and limited capacity.

Need to solve

Given the need to transport large and heavier wire coils, it is necessary to design and install a handling system with integrated weighing. It is also essential that the weighing accuracy is 0.1 %.

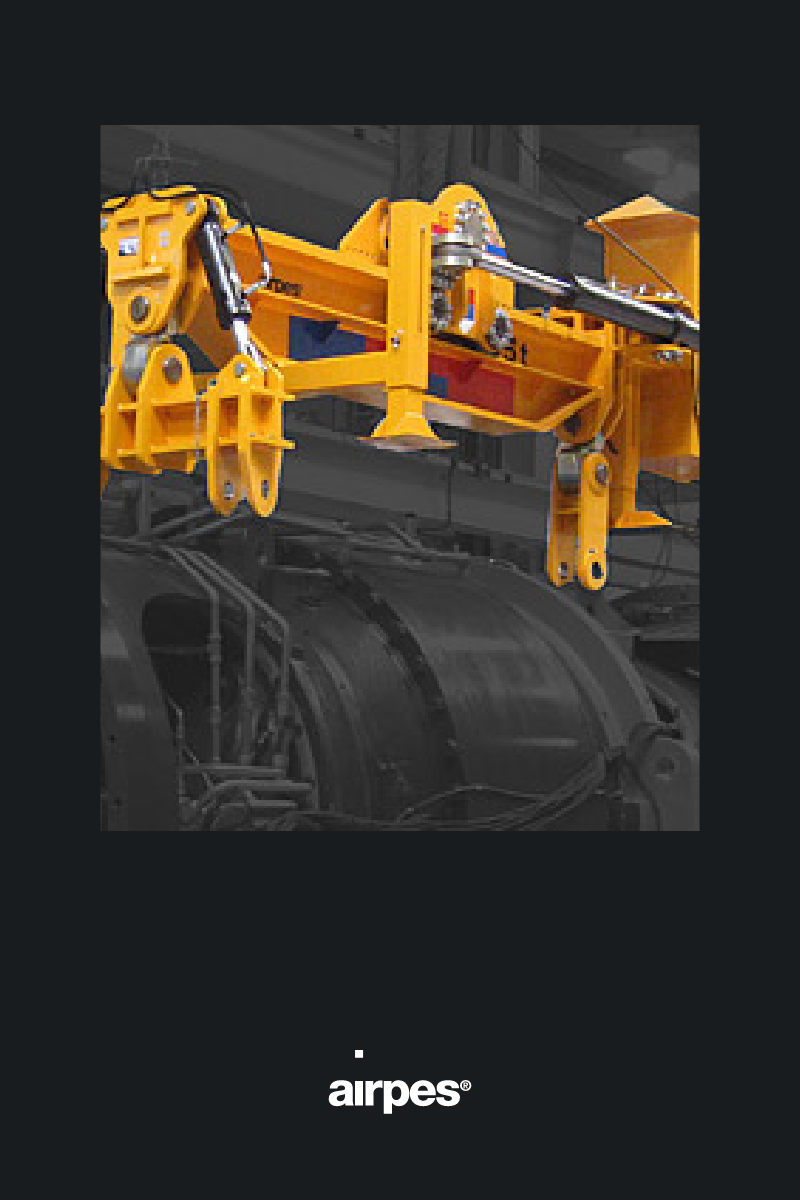

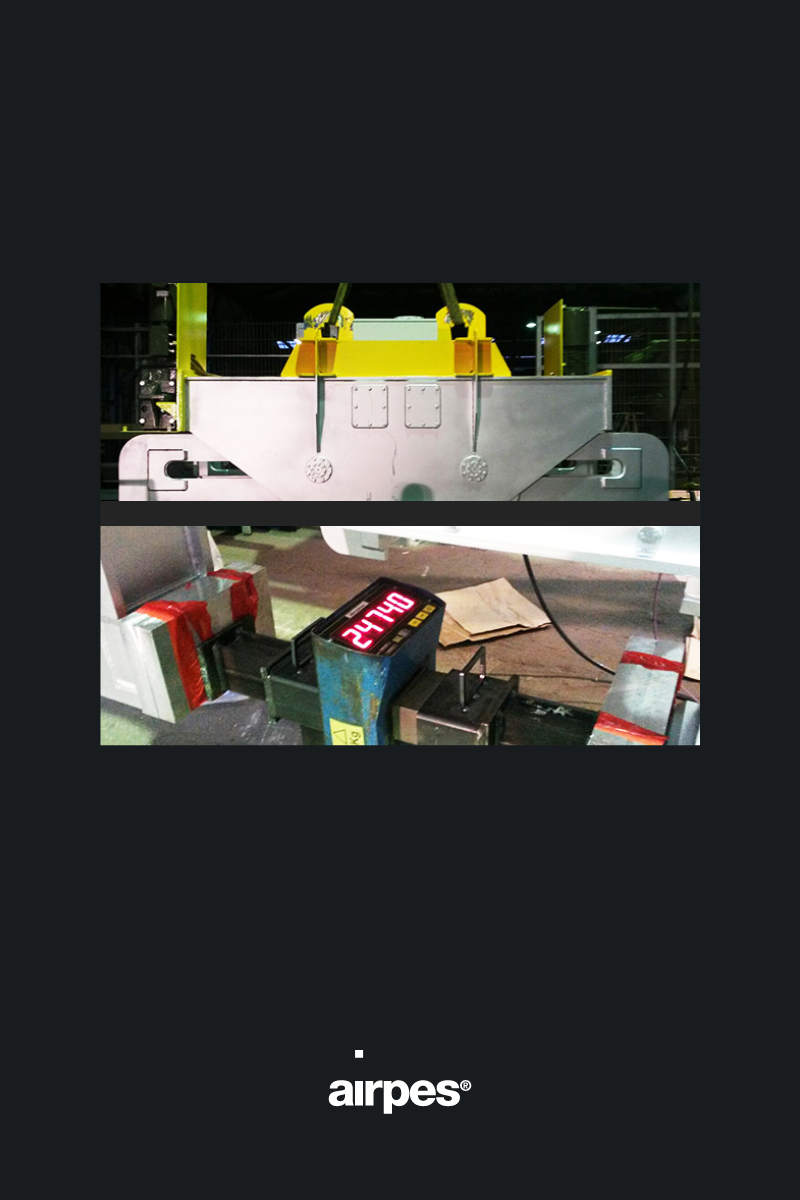

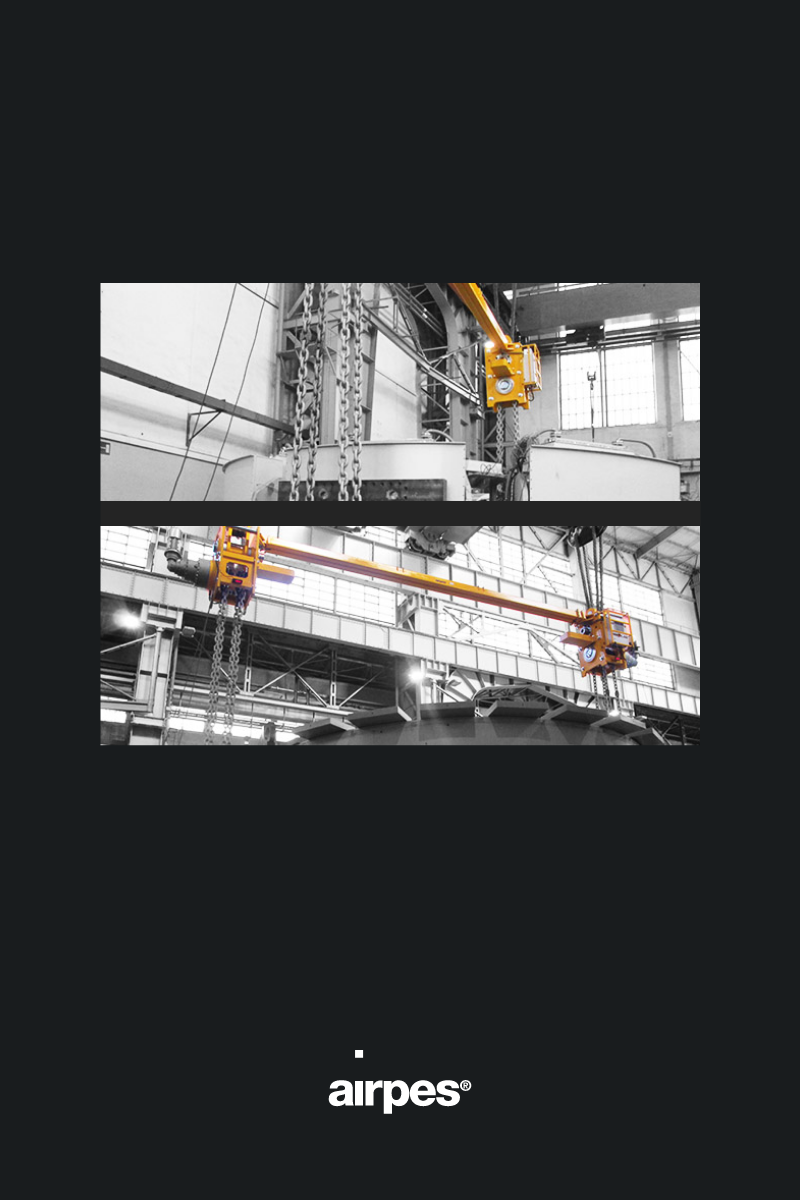

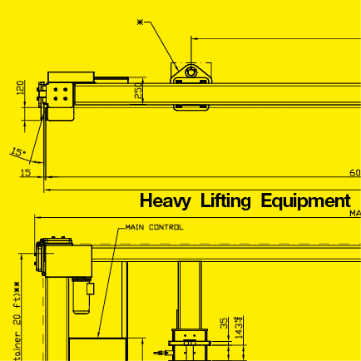

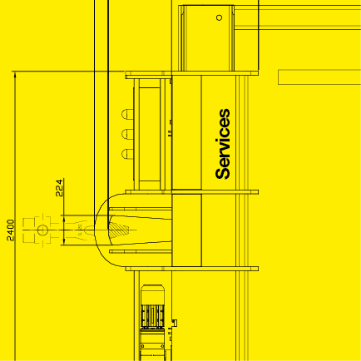

Airpes technicians designed a tubular seesaw with weighing in a double frame and limited inclination to guarantee an 0.1% accuracy.

Airpes also installed the AMR130RE Viewer showing the precise weight of the crane throughout the workspace. A radio system is also incorporated to send the weight information to the computer, keeping it stored.

With optional PC data transmission, the client gains flexibility and immediate access to information about their products.

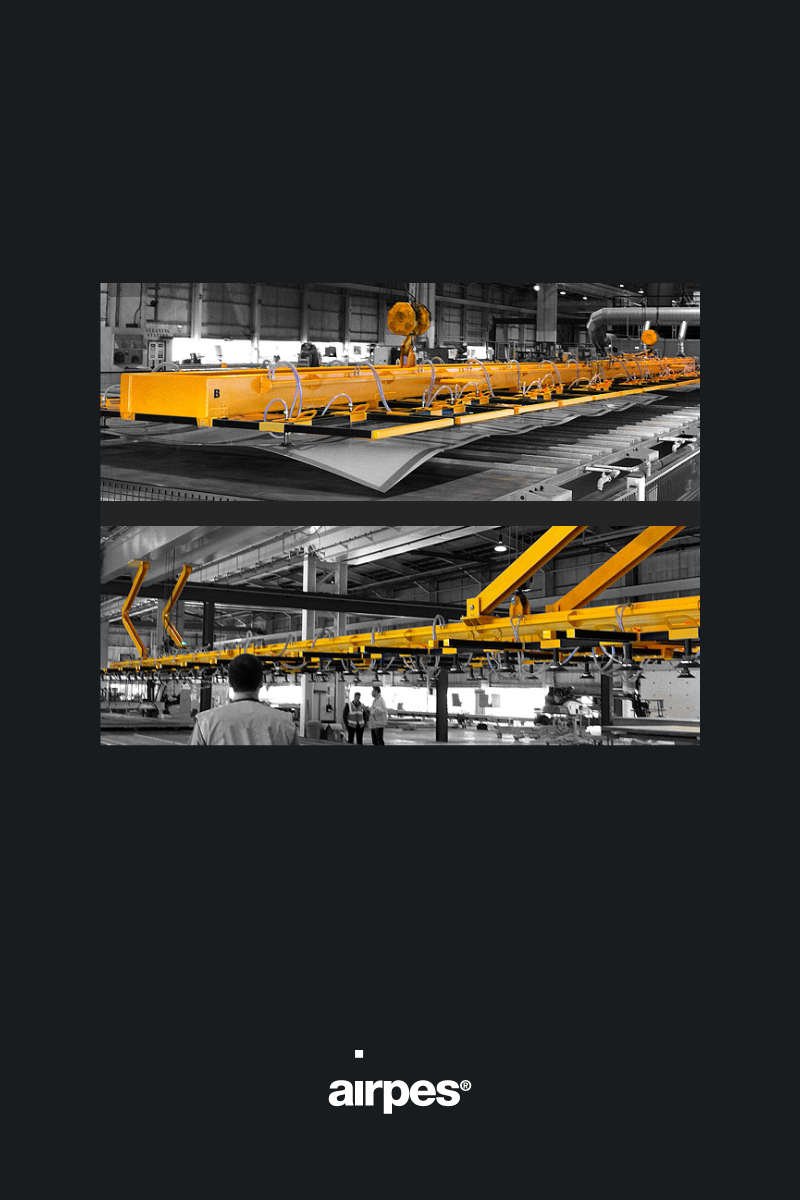

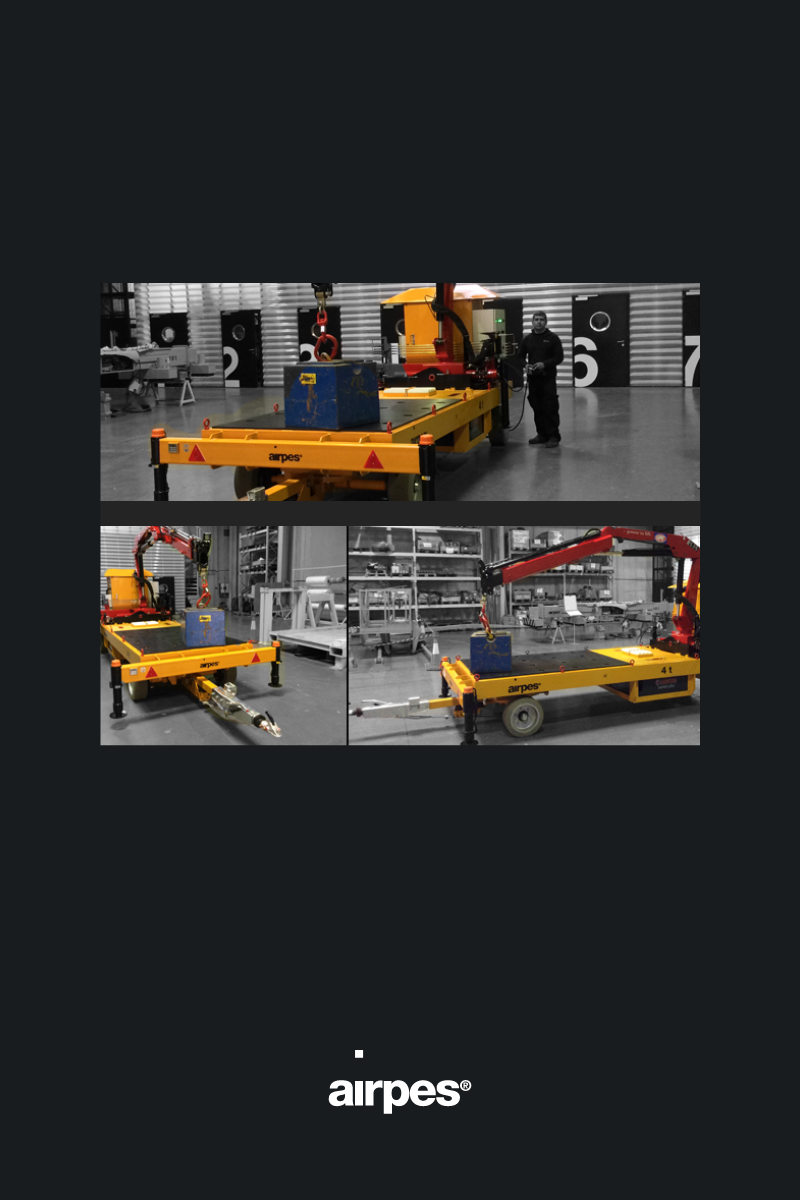

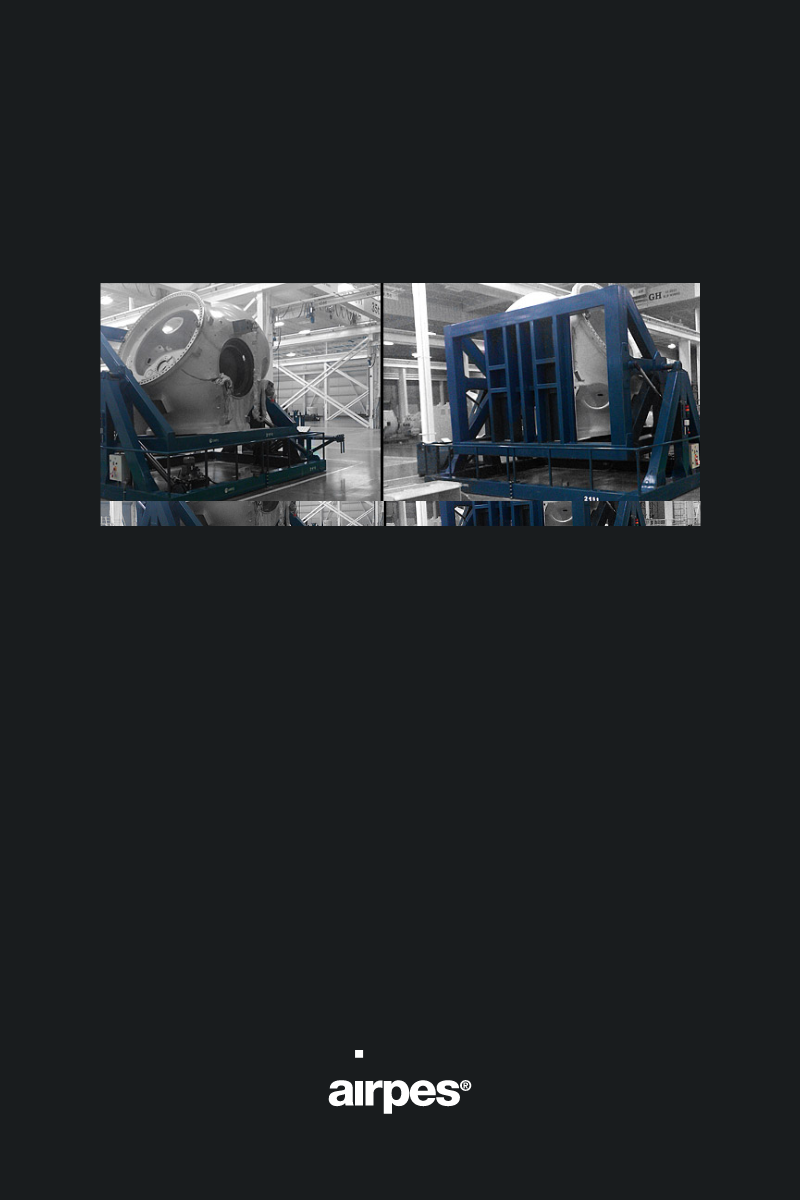

OUR on demand solutions

Airpes Solutions

LATEST POSTS ON THE BLOG

Discover our brand new developments, events, get posted of our activity.

- Types of lifting tongsDiscover how Crosby Airpes' lifting tongs design is made to safely grab and lift various materials and objects...

- Lifting tongs design: the most precise toolDiscover how Crosby Airpes' lifting tongs design is made to safely grab and lift various materials and objects...

- Benefits of adjustable lifting beams to your businessAdjustable lifting beams offer versatile solutions for various load sizes and shapes, reducing the need for multiple beams,...

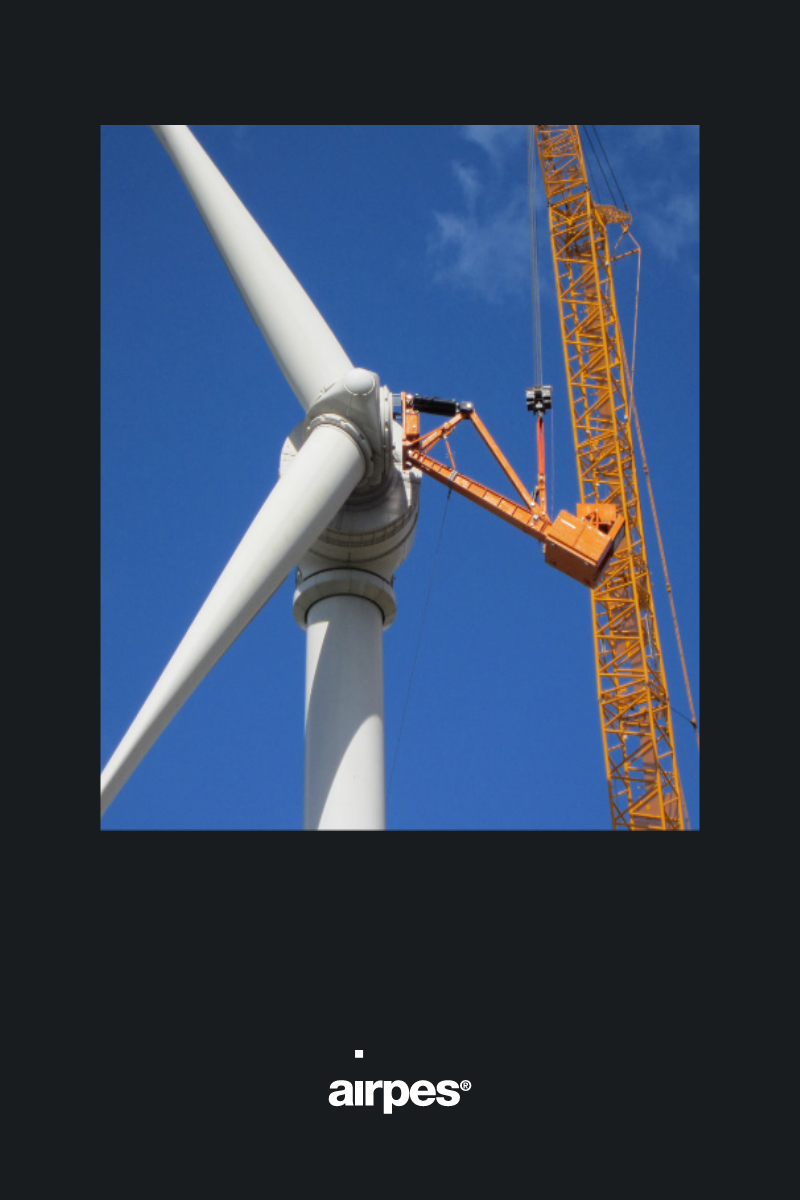

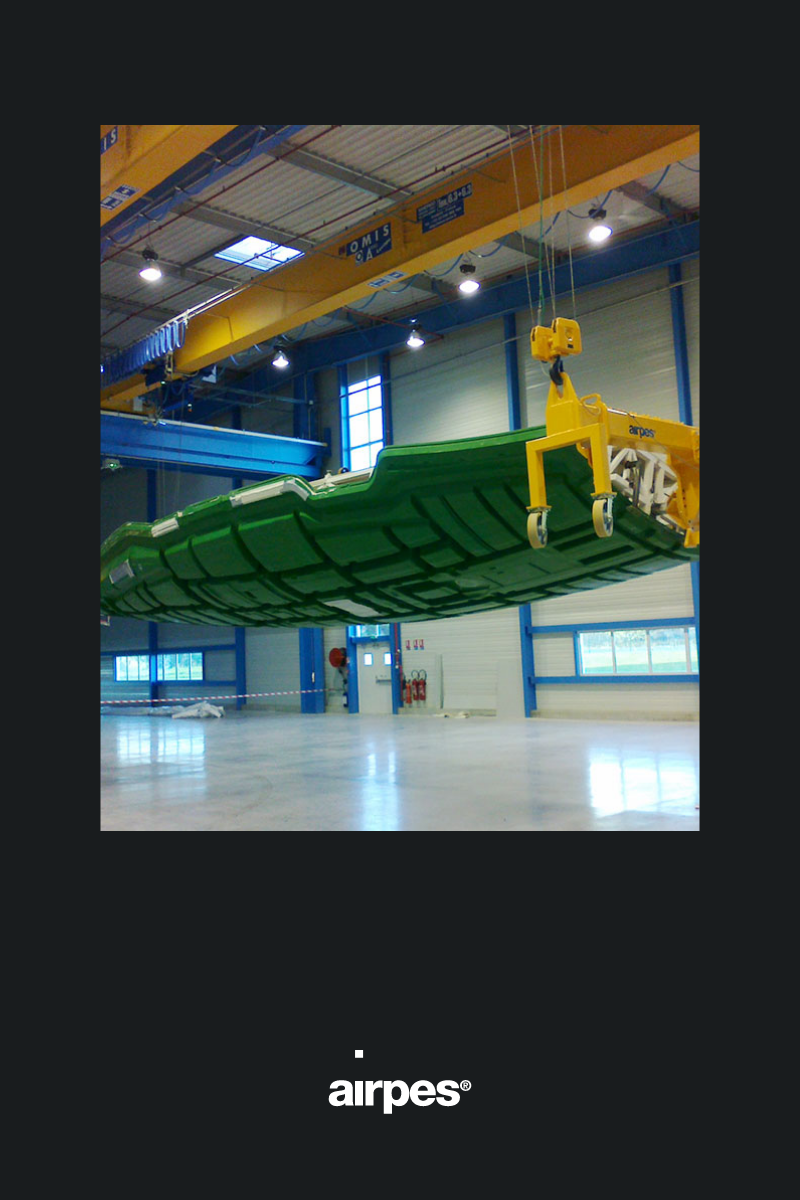

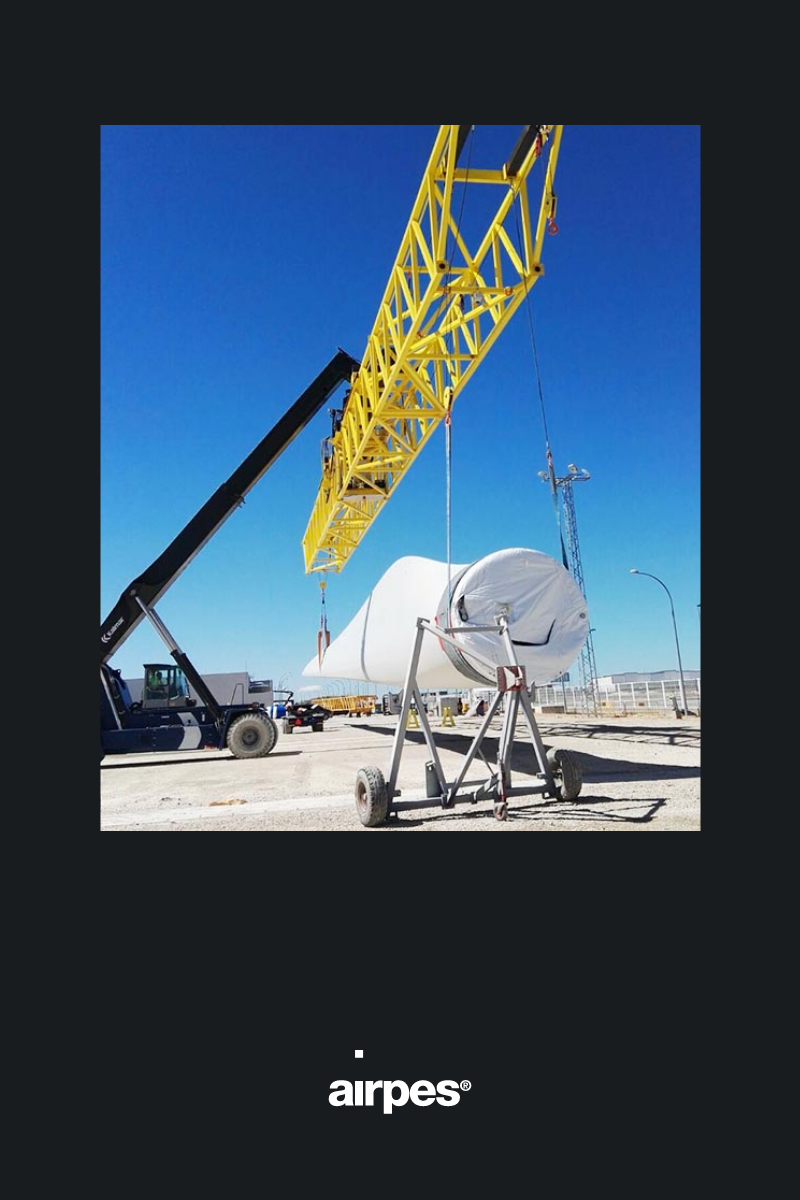

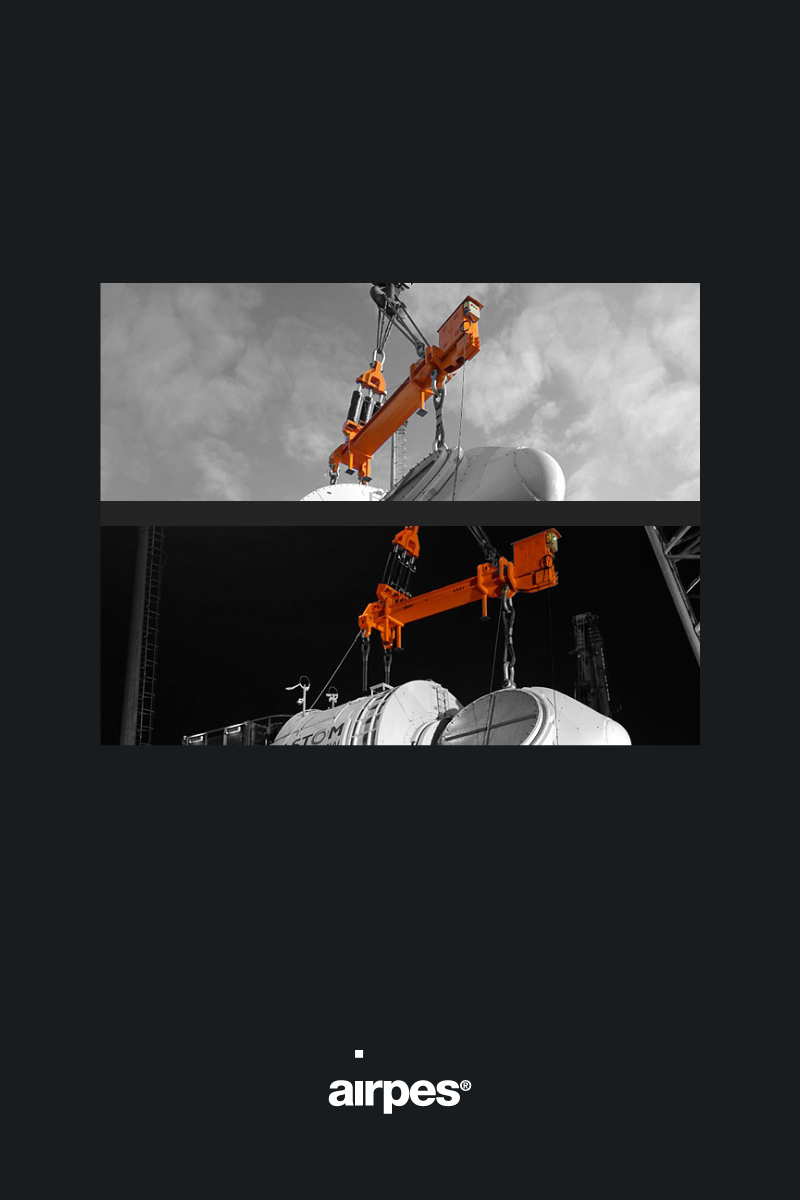

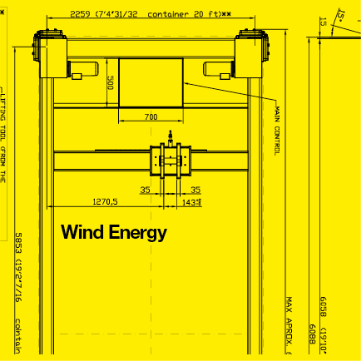

- Integral solution for the installation and maintenance of wind turbine bladesAn integral solution for the installation and maintenance of wind turbine blades. Adapting Yoke Blade Clamps with our...